You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clarke 100EN - PCB

- Thread starter Ianh99

- Start date

Itfluxmeoff

Member

- Messages

- 38

- Location

- Scotland

If it works don't fix it!

Good advice - but I'm trying to determine whether the difficulty in getting a decent weld is down to my own rudimentary welding skills, or the possible shortcomings of the machine which was secondhand to me, and which I know has been messed with previously.If it works don't fix it!

Itfluxmeoff

Member

- Messages

- 38

- Location

- Scotland

Describe the difficulty you are experiencing.

mike 109444

Member

- Messages

- 4,805

If you are having or suspecting feed issues then check for cracks in the black plastic pressure roller arm and it's mounting as that was a known issue. Also oevr pressure of the arm and asuport bracket could be fitted.

Thanks everyone. I am having great difficulty in getting a continuous weld with good penetration. The manual suggests that the feed speed should automatically change with different switch settings, but mine remains constant across all settings, when measured across the motor, with the trigger pulled. I can though, change the speed on the rotary control quite effectively.

Just me overthinking perhaps.

Good point, thanks.I suspect the component is original given it is copper riveted to the heatsink, doubt anyone would do that DIY. Might have been unsoldered complete with heatsink for testing and refitted though.

Just me overthinking perhaps.

Alan Reynolds

Member

- Messages

- 1,304

I have an SIP Mig ate and it suffered all sorts of problems with horrible welds. Sticking feed rates etc.

I have an idea the Clarke is similar in construction internally.

I assumed it was just a cheap welder but I wasn’t too fussed as I’d got it for a song as a non working unit. The fault was just a switch on the front, halfway between,

I modded the wire feed bracket. Made my own wire feed pressure arm. Fitted a steel liner to replace the plastic one. Fitted a separate power supply for the wire feed motor. Fitted a separate wire feed trim potentiometers and ditched the pub co2 gas for a Hobbyweld argon/co2 mix.

WHAT A DIFFERENCE IN THE MACHINE NOW.

When it welds it sound like bacon sizzling

All this was due to the massive help I got from the lads on this site

I’ll post a little video later of my modifications.

I have an idea the Clarke is similar in construction internally.

I assumed it was just a cheap welder but I wasn’t too fussed as I’d got it for a song as a non working unit. The fault was just a switch on the front, halfway between,

I modded the wire feed bracket. Made my own wire feed pressure arm. Fitted a steel liner to replace the plastic one. Fitted a separate power supply for the wire feed motor. Fitted a separate wire feed trim potentiometers and ditched the pub co2 gas for a Hobbyweld argon/co2 mix.

WHAT A DIFFERENCE IN THE MACHINE NOW.

When it welds it sound like bacon sizzling

All this was due to the massive help I got from the lads on this site

I’ll post a little video later of my modifications.

That's great Alan. Thanks!I have an SIP Mig ate and it suffered all sorts of problems with horrible welds. Sticking feed rates etc.

I have an idea the Clarke is similar in construction internally.

I assumed it was just a cheap welder but I wasn’t too fussed as I’d got it for a song as a non working unit. The fault was just a switch on the front, halfway between,

I modded the wire feed bracket. Made my own wire feed pressure arm. Fitted a steel liner to replace the plastic one. Fitted a separate power supply for the wire feed motor. Fitted a separate wire feed trim potentiometers and ditched the pub co2 gas for a Hobbyweld argon/co2 mix.

WHAT A DIFFERENCE IN THE MACHINE NOW.

When it welds it sound like bacon sizzling

All this was due to the massive help I got from the lads on this site

I’ll post a little video later of my modifications.

Itfluxmeoff

Member

- Messages

- 38

- Location

- Scotland

There are many variables to consider and your description isn't very detailed.Thanks everyone. I am having great difficulty in getting a continuous weld with good penetration. The manual suggests that the feed speed should automatically change with different switch settings, but mine remains constant across all settings, when measured across the motor, with the trigger pulled. I can though, change the speed on the rotary control quite effectively.

Good point, thanks.

Just me overthinking perhaps.

The wire feed indeed changes with power settings so it's more or less set and forget.

To test the changing speed, flip the wire feed pressure roller tensioner down so the wire won't feed. Pull the trigger in all power settings and you should hear a subtle change in the wire feed motor speed.

To refresh, tell us what wire you're using, polarity config, what you're welding, welder settings etc.

With all electronic equipment, components are usually the last thing to be 'wrong', or at least should be the last thing to check when basic functionality is present. Especially with welders, that will likely spend their lives in environments that are not only grimy but thick with conductive metal dust particles, the first thing to check are the switches and the feed system (as mentioned above). They can easily collect grot and it can all add up to poor welding. It's a lot easier to check these systems than delve immediately into component-level troubleshooting, too!

In this case, the component circled is a generic fast-switching NPN transistor so unless faked there's not much that could be wrong with it (and no reason for it to be altered, since it's a totally normal type of component and very unlikely to be part-number critical). There's no evidence of circuit board damage or overload in your photograph that would point to a significant electrical problem.

The inside looks clean. Have you done the usual checks and maintenance like ensuring the feed rollers are in good condition, the switch contacts are clean, the liner is good and the tip isn't worn out? A spray with a switch cleaner (Kontakt Chemie 10 is a good standby, though the WD40-branded contact cleaner may be more widely available in your local shop - not normal WD40, I hasten to add) coupled with operating the switch many times will clean the contacts.

In this case, the component circled is a generic fast-switching NPN transistor so unless faked there's not much that could be wrong with it (and no reason for it to be altered, since it's a totally normal type of component and very unlikely to be part-number critical). There's no evidence of circuit board damage or overload in your photograph that would point to a significant electrical problem.

The inside looks clean. Have you done the usual checks and maintenance like ensuring the feed rollers are in good condition, the switch contacts are clean, the liner is good and the tip isn't worn out? A spray with a switch cleaner (Kontakt Chemie 10 is a good standby, though the WD40-branded contact cleaner may be more widely available in your local shop - not normal WD40, I hasten to add) coupled with operating the switch many times will clean the contacts.

Alan Reynolds

Member

- Messages

- 1,304

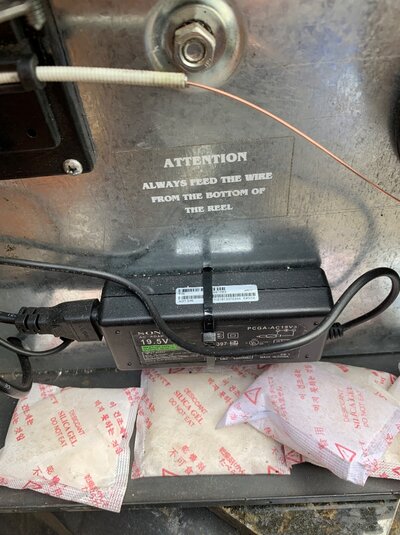

I didn’t know how to post a video, so I took some pictures.

The fine wire feed adjuster is a ten turn potentiometers, soldered in the lace of the original trim pot for the wire feed.

The fine wire feed adjuster is a ten turn potentiometers, soldered in the lace of the original trim pot for the wire feed.

Wow! Some mods there Alan! Thanks for the pics. I'll bear these in mind

I have looked for a variation in the feed speed, by checking the voltage at the feed motor, which I thought may make it easier to discern any speed variations that a visual check. At any given voltage (as set by the rotary knob) the voltage remains constant across all current settings.

I am sure that with my 0.8mm practice sheet, I should get a semi-reasonable bead. I am on no -gas, with the polarity set accordingly. Having checked, cleaned all the switches and connections, replaced the earth clamp and replaced the aluminium splice with a four terminal earth block, I'll see how she performs over the next couple of days. Thanks again.

Thanks for your reply.There are many variables to consider and your description isn't very detailed.

The wire feed indeed changes with power settings so it's more or less set and forget.

To test the changing speed, flip the wire feed pressure roller tensioner down so the wire won't feed. Pull the trigger in all power settings and you should hear a subtle change in the wire feed motor speed.

To refresh, tell us what wire you're using, polarity config, what you're welding, welder settings etc.

I have looked for a variation in the feed speed, by checking the voltage at the feed motor, which I thought may make it easier to discern any speed variations that a visual check. At any given voltage (as set by the rotary knob) the voltage remains constant across all current settings.

I am sure that with my 0.8mm practice sheet, I should get a semi-reasonable bead. I am on no -gas, with the polarity set accordingly. Having checked, cleaned all the switches and connections, replaced the earth clamp and replaced the aluminium splice with a four terminal earth block, I'll see how she performs over the next couple of days. Thanks again.

Are you using flux wire and not mild steel wire if your on no gas settingWow! Some mods there Alan! Thanks for the pics. I'll bear these in mind

Thanks for your reply.

I have looked for a variation in the feed speed, by checking the voltage at the feed motor, which I thought may make it easier to discern any speed variations that a visual check. At any given voltage (as set by the rotary knob) the voltage remains constant across all current settings.

I am sure that with my 0.8mm practice sheet, I should get a semi-reasonable bead. I am on no -gas, with the polarity set accordingly. Having checked, cleaned all the switches and connections, replaced the earth clamp and replaced the aluminium splice with a four terminal earth block, I'll see how she performs over the next couple of days. Thanks again.

Itfluxmeoff

Member

- Messages

- 38

- Location

- Scotland

Is the wire feed motor PWM driven? That would appear as a constant voltage on some DMMs. You can't go wrong listening to the speed of the motor... unless you're tone deaf!

Is the wire feed motor PWM driven? That would appear as a constant voltage on some DMMs. You can't go wrong listening to the speed of the motor... unless you're tone deaf!

Use analog meter or small bulb

Or use voice recorder on phone, look at the pattern on screen

This small MIG welder has no "auxiliary power supply" ( i.e. a medium-sized 12v or 24v transformer and rectifier ),

The small potted transformer on the PCB only runs the power-up relay, via the torch trigger.

Power for the wirefeed motor has to come from the main DC welding output. This voltage varies with the setting of the "1/2" and "Min/Max" switches. If the motor speed control is PWM, the variable control will alter the width of the pulses, but when the supply voltage changes, the voltage level of those pulses will change.

The small potted transformer on the PCB only runs the power-up relay, via the torch trigger.

Power for the wirefeed motor has to come from the main DC welding output. This voltage varies with the setting of the "1/2" and "Min/Max" switches. If the motor speed control is PWM, the variable control will alter the width of the pulses, but when the supply voltage changes, the voltage level of those pulses will change.

I've taken something of a backward step guys!

I removed the heatsunk npn transistor from the board to check it. All tested fine. Reassembled everything and powered up. Switch light comes on and fan runs - but now no feed when trigger pulled! Relay failing to operate too. I've metered the trigger and that's functioning as it should.

I have approx 30vac on the pcb transformer secondary. I've reflowed several of the connections on the pcb - but still nothing!

Wish I'd left it well alone now!

There is clearly more to the pcb than the simplistic diagram in the manual!

Does anyone have a full schematic for an E1289 board please?

I'm at a loss here!

Thanks

I removed the heatsunk npn transistor from the board to check it. All tested fine. Reassembled everything and powered up. Switch light comes on and fan runs - but now no feed when trigger pulled! Relay failing to operate too. I've metered the trigger and that's functioning as it should.

I have approx 30vac on the pcb transformer secondary. I've reflowed several of the connections on the pcb - but still nothing!

Wish I'd left it well alone now!

There is clearly more to the pcb than the simplistic diagram in the manual!

Does anyone have a full schematic for an E1289 board please?

I'm at a loss here!

Thanks