You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carbide boring bars

- Thread starter RichardM

- Start date

Solid carbide for only 86p including shipping! ttps://www.aliexpress.com/item/1005005378697314.html

What size and insert type are you after? I bought this C08M-SCLCR06 for a long 12mm bore https://www.aliexpress.com/item/1005004217397251.html

What size and insert type are you after? I bought this C08M-SCLCR06 for a long 12mm bore https://www.aliexpress.com/item/1005004217397251.html

I've not got an 8mm steel to compare, but on my worn out ML7 I can't tell the difference between a 12mm steel and that 8mm carbide, both use the same insert.C08M-SCLCR06, that one would do. How does it compare to to a steel one of the same size for flex?

Kram

Member

- Messages

- 8,521

- Location

- Sussex

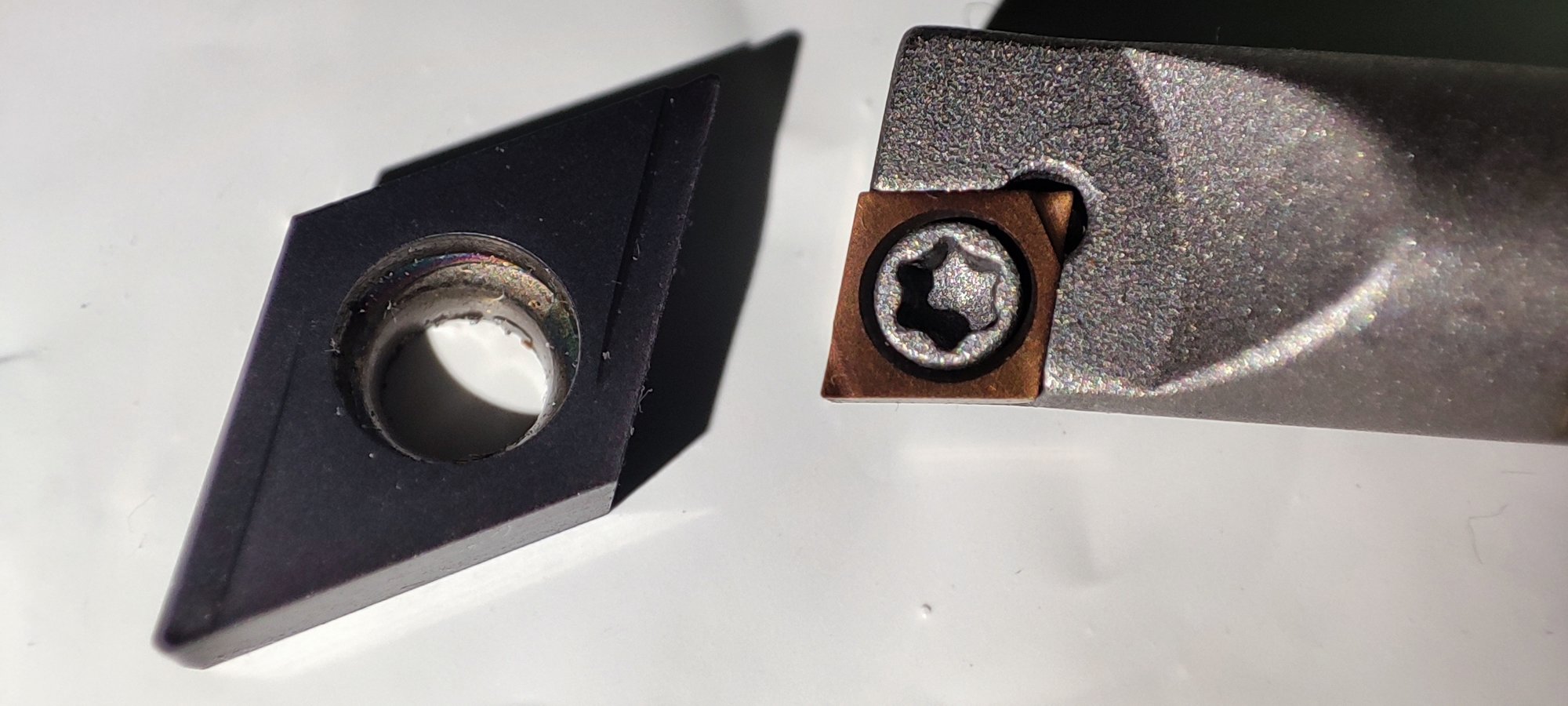

Ccmt06's are not much good below 10mm bore. The insert is 2.4mm thick, and the seat wants to be the same, near 5mm and double it.

If you want smaller bores, I'd recommed a smaller insert, i'll find my post..

Edit, Id recommend this sort for smaller bores.

Inserts: TBGT060101, bar C06K-STUBR06. I believe that should do a 7mm bore.

I got these

If you want smaller bores, I'd recommed a smaller insert, i'll find my post..

Edit, Id recommend this sort for smaller bores.

Inserts: TBGT060101, bar C06K-STUBR06. I believe that should do a 7mm bore.

I got these

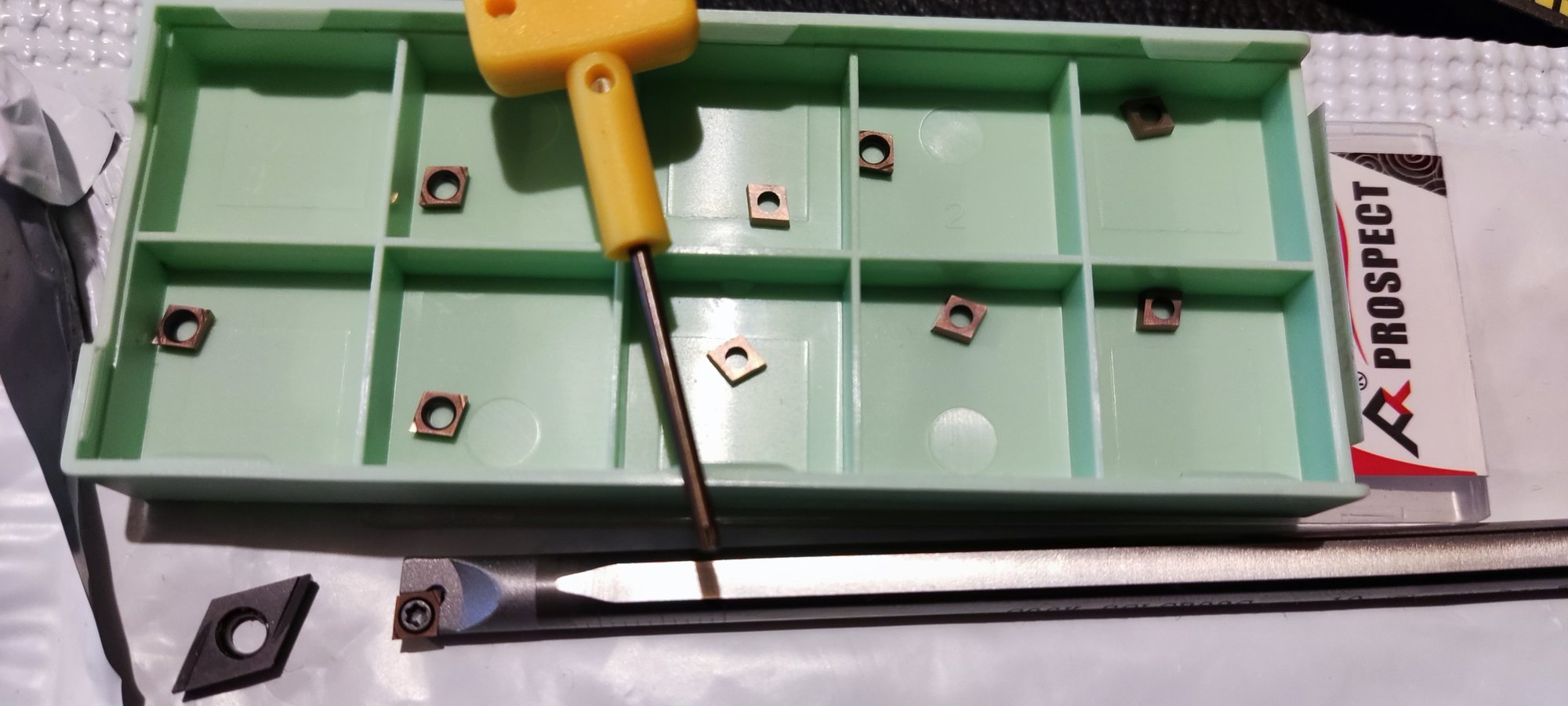

A pack of CCGT030101L-F inserts and a C06-SCLCR03 boring bar. The DCMT0702 insert for size, they are tiny!

Agroshield

Member

- Messages

- 6,386

How does it compare to to a steel one of the same size for flex?

Deflection formula for cantilever beam here:

The only thing that differs between steel and carbide, is E, the Young's modulus. As the formula shows, deflection is proportional to E. The E value for steel is 200 GPa; for carbide it is in excess of 500 GPa. Hence, minimum 2 1/2 times as stiff, so 40% the deflection.

northwest

Searching for the Holy Grail.........

- Messages

- 6,715

- Location

- Manchester UK

am really looking to standardise with as few insert sizes as possible.

Good luck with that, let me know how you get on............

Kram

Member

- Messages

- 8,521

- Location

- Sussex

An 8mm bar will only have 1.6mm of steel under the seat - it is standard for the insert to be on centre of the bar, even if it wont physically fit in an 8mm hole. They are angled 15 degrees or so which gives a little bit more meat under there, but not much.

Munkul

Jack of some trades, Master of none

- Messages

- 7,776

- Location

- Cumbria

carbide bars are superb compared to steel, you can stick them way out to 5x D, maybe 7x D and they don't chatter half as bad, even the cheap bars.C08M-SCLCR06, that one would do. How does it compare to to a steel one of the same size for flex?

They aren't however, a magic fix for trying to stick out say 10x D, or something stupid like that

I'd have an 04 insert on an 08 bar.

Keep the 06 inserts for 10 upwards.

If you're spending money, you may as well spend it right.

I have a cheap set of 08, 10 and 12 bars that take 06 inserts, however I've never used the 08 bar as I have another 08 bar made by mitsubishi that uses tiny trigon inserts, and that bar is magic.

I did 85mm long 12mm bore in O2 steel with the 8mm carbide bar I linked above, it was not fun, ended up taking tiny cuts with an aluminium type insert. Definitely a one off hobbyist kind of job, wouldn't be making money like that.a magic fix for trying to stick out say 10x D, or something stupid like that

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Aye, superb wee bars.....as I have another 08 bar made by mitsubishi that uses tiny trigon inserts, and that bar is magic.

Erie Fred

Member

- Messages

- 6,669

- Location

- Erie, Pa USofA

Or a toolmaker.I did 85mm long 12mm bore in O2 steel with the 8mm carbide bar I linked above, it was not fun, ended up taking tiny cuts with an aluminium type insert. Definitely a one off hobbyist kind of job, wouldn't be making money like that.

Munkul

Jack of some trades, Master of none

- Messages

- 7,776

- Location

- Cumbria

I don't have the patience for that kind of thing, it would be a drilled hole if not critical, or I'd buy a reamer if it was critical...I did 85mm long 12mm bore in O2 steel with the 8mm carbide bar I linked above, it was not fun, ended up taking tiny cuts with an aluminium type insert. Definitely a one off hobbyist kind of job, wouldn't be making money like that.

Kram

Member

- Messages

- 8,521

- Location

- Sussex

Link or details pleaseI have another 08 bar made by mitsubishi that uses tiny trigon inserts, and that bar is magic.