You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brazing rods/flux

- Thread starter GraemeVW

- Start date

GraemeVW

Member

- Messages

- 1,709

- Location

- Chesterfield

I'll either file it, or someone offered to cut it properly.How are you planning to shape the built up tooth?

Tig with sillicon bronze may work, easy enough to do Id say, lots of members have tig.

Best option perhaps, have a new gear cut. A few members on here seem to have the kit and know how to do it.

Shaping the tooth isn't high on my list of concerns.

GraemeVW

Member

- Messages

- 1,709

- Location

- Chesterfield

Yep. I have a wood burner in the workshop. Plan is to pre heat it as much as I can with that, then work on it encased in 50mm of vermiculite board.If you are going to try to braze it with map you will need some radiants around it to retain the heat.

I'll use the wood burner to keep the cool down controlled too.

I've had large ish bolts glowing hot like this when I wanted to undo the heat treatment. It managed it quite easily.

The gear will be pushing what I can do though, but I'm going to at least try. All ill waste is some time and some gas.

I used these https://www.amazon.co.uk/gp/product/B083PX5LJM/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1 and filed/grinder to shape, maybe only 5 hours total running since but fine so farTig with sillicon bronze may work, easy enough to do Id say, lots of members have tig.

GraemeVW

Member

- Messages

- 1,709

- Location

- Chesterfield

Exactly the ones I've orderedI used these https://www.amazon.co.uk/gp/product/B083PX5LJM/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1 and filed/grinder to shape, maybe only 5 hours total running since but fine so far

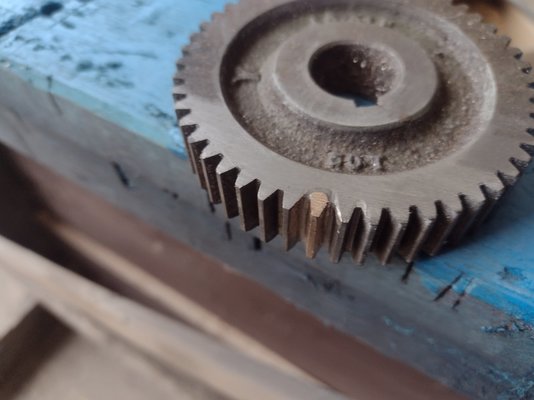

View attachment 399601

GraemeVW

Member

- Messages

- 1,709

- Location

- Chesterfield

That just jogged my memory. Those were listed as tig or gas, but at 1000° melting point.incase any confusion that was with TIG...

I thought that was too high so thought I'd better go check which ones I actually did order!

Seems I ordered these as they are 800° or thereabouts.