You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

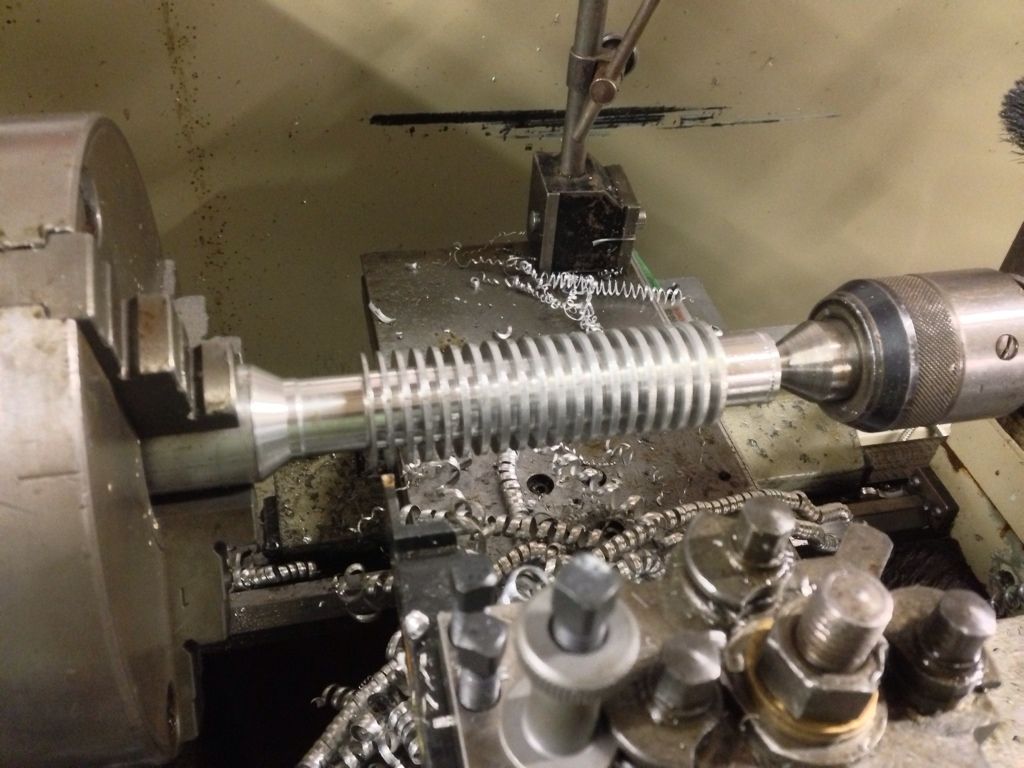

Been playing on the lathe

- Thread starter chris-law

- Start date

aametalmaster

Member

- Messages

- 763

- Location

- Salem Ohio USA

Nice work for sure...Bob

pedrobedro

Man at Matalan

- Messages

- 13,078

- Location

- CX near Chesterfield

I thought it was a light sabre handle

Very good Chris, see the dros been put to good use.

Im having problems with the dro , the cross axis keeps counting down on its own , as soon as you power the lathe off it stops

.

.Thats nothing compared to the work you produce pal , its a start though

Wait until you start with the milling. That will get your head in knots, in a good way.

Yes i spent a couple of hours spinning an impeller on the lathe only to ruin it in 2 mins on the mill

, now i know why i need a rotary table

, now i know why i need a rotary tableNice work. Is that before or after the rad?

Its after the rad , i was having overheating issues when the going gets tough , im hoping this helps out , you can buy them at £30 a pop but i thought it would be good practice to make one

atomant48

Member

- Messages

- 1,846

- Location

- Salisbury, UK

Its after the rad , i was having overheating issues when the going gets tough , im hoping this helps out , you can buy them at £30 a pop but i thought it would be good practice to make one

Might help cutting some swirl inducers into the bore as well if the pump has enough grunt.

Pete.

Member

- Messages

- 14,940

- Location

- Kent, UK

Yes of course. This is what I use to sharpen carbide and it works great:

http://www.ebay.co.uk/itm/4-100mm-D...Home_Garden_PowerTools_SM&hash=item2a2a8246ff

http://www.ebay.co.uk/itm/4-100mm-D...Home_Garden_PowerTools_SM&hash=item2a2a8246ff

Chris could try a separate earth to see if that cures. Theres usually an earth terminal on back of readout.

Saying that i do have same problems on the lathe tailstock magnetic until i move it once any direction. 2 axis on mill do the same now and again notably the downfeed and X axis. a strip down and clean of glass sorts but yours is the magnetic.

Have a word with Machine DRO and tell them you are not the only one.

Saying that i do have same problems on the lathe tailstock magnetic until i move it once any direction. 2 axis on mill do the same now and again notably the downfeed and X axis. a strip down and clean of glass sorts but yours is the magnetic.

Have a word with Machine DRO and tell them you are not the only one.

octo0072000

Member

- Messages

- 5,992

- Location

- south yorks

by the look of the rad the fins dont look very good for airflow at the bottom end looks like it's been jet washed too many times

jet washing rads/inter coolers is not a good idea flattens the fins so no airflow then gets too hot seen it done loads of times at off road play days

jet washing rads/inter coolers is not a good idea flattens the fins so no airflow then gets too hot seen it done loads of times at off road play days

Chris could try a separate earth to see if that cures. Theres usually an earth terminal on back of readout.

Saying that i do have same problems on the lathe tailstock magnetic until i move it once any direction. 2 axis on mill do the same now and again notably the downfeed and X axis. a strip down and clean of glass sorts but yours is the magnetic.

Have a word with Machine DRO and tell them you are not the only one.

Typical , it didnt do it today at all .

You dont happen to have any edct or edpt inserts do you , i won a kennametal 50mm facemill on ebay for a grand total of £12

, without inserts and they are a bit scarce on the bay .

, without inserts and they are a bit scarce on the bay .Looks like ill have to pick up one o those wheels pete

by the look of the rad the fins dont look very good for airflow at the bottom end looks like it's been jet washed too many times

jet washing rads/inter coolers is not a good idea flattens the fins so no airflow then gets too hot seen it done loads of times at off road play days

I know it does look like that on the pic , i take care not to do that though , but some i may have cought

, too late now , its a great forum this with everybody helping with tips whenever possible

, too late now , its a great forum this with everybody helping with tips whenever possible