You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Balance

- Thread starter Cheesie

- Start date

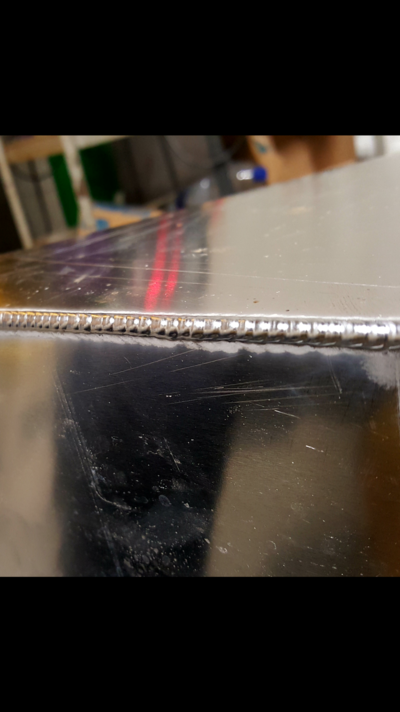

Oops the bit I'd written didn t seem to be added I'm struggling to get the balance right without so much white around the weld from the cleaning process, when I go into less cleaning the pool acts like water being poured over the job if that makes sense and is less controllable,

so I always end up stuck around the same setting this is on the welder in work a parweld xtt202 pulse

so I always end up stuck around the same setting this is on the welder in work a parweld xtt202 pulse

hotponyshoes

Member

- Messages

- 7,932

- Location

- Somerset. Uk

I would be happy with any of those welds.

I'm not very good at alloy tig but as you said, that white stuff is the oxides that have been pushed out of the weld.

It's done the job well as all the welds look nice and clean.

To reduce the amount of white you would need to reduce the amount of contaminants in the weld.

The metal itself looks like it was clean enough before welding, you could try wiping it off with acetone just before welding. Also wipe off the filler rod and use a clean glove. Keep the end of the filler rod inside the gas shield as you are welding (looks like you have done that anyway)

Basically, that contamination has come from somewhere and the right thing has happened when it has got pushed out of the way so get rid off as much as you can before welding. I suspect there will always be some impurities throughout the metal that you will not be able to remove just with a surface clean though. I have certainly never achieved a good weld without getting the white bit.

You could try a stainless brush before wiping on some test bits and see if it improves?

One of the more experienced guys will be along to give you some more advice soon...

I'm not very good at alloy tig but as you said, that white stuff is the oxides that have been pushed out of the weld.

It's done the job well as all the welds look nice and clean.

To reduce the amount of white you would need to reduce the amount of contaminants in the weld.

The metal itself looks like it was clean enough before welding, you could try wiping it off with acetone just before welding. Also wipe off the filler rod and use a clean glove. Keep the end of the filler rod inside the gas shield as you are welding (looks like you have done that anyway)

Basically, that contamination has come from somewhere and the right thing has happened when it has got pushed out of the way so get rid off as much as you can before welding. I suspect there will always be some impurities throughout the metal that you will not be able to remove just with a surface clean though. I have certainly never achieved a good weld without getting the white bit.

You could try a stainless brush before wiping on some test bits and see if it improves?

One of the more experienced guys will be along to give you some more advice soon...

AndersK

Member

- Messages

- 1,469

- Location

- Sweden

Are you using a gas lens?

There are people adamant to using a std collet with a #5 cup only on aluminium which is said to reduce the etched zone.

I have not experimented much with this but it looks to reduce a bit.

What balance are you running at? I am usually at 35-45% with my XTI202

15% will take away most of the etching

There are people adamant to using a std collet with a #5 cup only on aluminium which is said to reduce the etched zone.

I have not experimented much with this but it looks to reduce a bit.

What balance are you running at? I am usually at 35-45% with my XTI202

15% will take away most of the etching

No gas lens no 6 shroud I seem to get my best welds at 35-38% the etching starts reducing at around 20% but it's hard to control the pool runs like liquid, maybe a wipe like what has been said, that won't happen in work as there is no time but give been asked to do more and more intricate parts from home that I want to have a better Finnish without taking a pad to

Munkul

Jack of some trades, Master of none

- Messages

- 7,757

- Location

- Cumbria

I run my handytig around 25% cleaning, it will go down to 20% on clean alloy but start getting some dirt in after that. What frequency?

Not really sure what you mean by the puddle is hard to control... you mean like it's a hotter weld? It will be... you're putting more energy into penetration and less into cleaning. So you might get away with a few less amps... not always.

Try a no.4 or 5 shroud instead?

To be fair, that's not all that bad... the mitred corner weld etched zone looks huge, but the other flat one looks similar to what I would usually get, maybe slightly larger, no more

Do you run with much stickout? Arc length?

Not really sure what you mean by the puddle is hard to control... you mean like it's a hotter weld? It will be... you're putting more energy into penetration and less into cleaning. So you might get away with a few less amps... not always.

Try a no.4 or 5 shroud instead?

To be fair, that's not all that bad... the mitred corner weld etched zone looks huge, but the other flat one looks similar to what I would usually get, maybe slightly larger, no more

Do you run with much stickout? Arc length?

Last edited: