Hi there, I have just switched my Clarke 100EN MIG welder over from CO2 to Argon/CO2 (75/25) mix and am having trouble adapting to it.

I have only just begun to do any sort of welding, and jumped in to doing some car body repairs to a decaying Morris. I borrowed the welder from a friend, which was supplied with 0.8 mild steel wire, and CO2 gas. Having just got to the point that my welds were coming out OK, and that I was getting a good feel for the process, the gas ran out. And after reading on the forums it seemed a good idea to spend a little more on the Argon mix.

So I did.

But now, although I can see how the welds can be much better than before, the behaviour of the welder is starkly different, which I had not anticipated. Whereas before the very tip of the wire touching the work area would be the molten area, now it seems a molten blob starts when the wire touches the metal, but then works its way UP the wire, growing larger and larger, before jumping/falling/popping on to the work area. This makes it very difficult to dictate where the metal ends up, and you can no longer properly weave along the join depositing metal and build up heat.

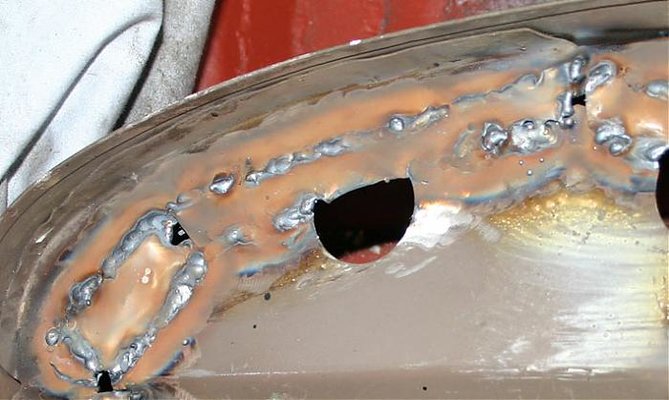

Below are a couple of photos of the work in question. They show a large area, and two close-ups before and after wire brushing. It is on some thin panels, using a bit of old PC case to patch. It seems after the welding there is a lot more brown residue than with CO2, but after cleaning up it is not too bad. The welder was set to 1 - Max for this work, wire speed 5ish.

So any tips/advice would be appreciated as I have working from the least critical areas of the car, building up ability and expereience as I work towards the more structural parts. And they are next, so it is important I am confident before tackling it. Oh, and that bit is upside down too, just for good measure.

I have only just begun to do any sort of welding, and jumped in to doing some car body repairs to a decaying Morris. I borrowed the welder from a friend, which was supplied with 0.8 mild steel wire, and CO2 gas. Having just got to the point that my welds were coming out OK, and that I was getting a good feel for the process, the gas ran out. And after reading on the forums it seemed a good idea to spend a little more on the Argon mix.

So I did.

But now, although I can see how the welds can be much better than before, the behaviour of the welder is starkly different, which I had not anticipated. Whereas before the very tip of the wire touching the work area would be the molten area, now it seems a molten blob starts when the wire touches the metal, but then works its way UP the wire, growing larger and larger, before jumping/falling/popping on to the work area. This makes it very difficult to dictate where the metal ends up, and you can no longer properly weave along the join depositing metal and build up heat.

Below are a couple of photos of the work in question. They show a large area, and two close-ups before and after wire brushing. It is on some thin panels, using a bit of old PC case to patch. It seems after the welding there is a lot more brown residue than with CO2, but after cleaning up it is not too bad. The welder was set to 1 - Max for this work, wire speed 5ish.

So any tips/advice would be appreciated as I have working from the least critical areas of the car, building up ability and expereience as I work towards the more structural parts. And they are next, so it is important I am confident before tackling it. Oh, and that bit is upside down too, just for good measure.

your welds aren't that bad really there's a lot worse on this forum

your welds aren't that bad really there's a lot worse on this forum