fourdegreesc

New Member

- Messages

- 3

Well, I hope I'm posting in the right place. This is a beginner question, but since it's about AL welding, it's not really beginner. I'm a tolerably good welder in steel and stainless, but this is my second attempt at AL and here are the results.

Terrible!

I've followed all the advice I could find online. I RTFM! I watched a dozen YouTube vids. I compiled a list of details to take care of but I absolutely must be missing something. Here's all the things I have done:

+ I have new metal, fresh from the supplier, 6061

+ Cleaned with a SS wire used only for AL

+ .035 wire, 4043 in a spool gun

+ 100% Argon, 15 LPM (I've tried more and less, and I've tried a LOT more and less)

+ put the ground on the piece itself

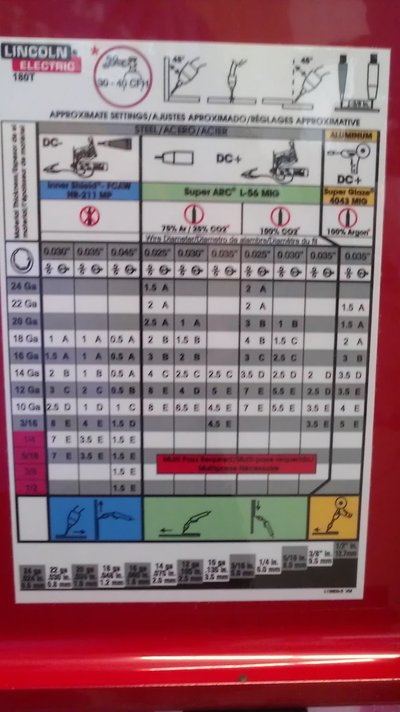

+ followed the settings on the welder case, tried nearby settings, mostly cooler and slower feed

+ welding in push direction on flat surface

I've burned myself several times and even that doesn't seem to help.

Have a look at the photos and feel free to make fun!

The welds are (black) sooty, not great penetration until suddenly the wire shoots out the other side to the table. I'm also getting white soot on the nozzle and feed gear, somewhat on the work piece too.

So the photos. The welds that look smooth and not AS terrible, that's the back side of piece. ALL my welds look the same.

The material is 1/8 inch, and I've tried dialing the heat down a bit (to D) and I've experimented with the speed from 2.5 to 4.5. The slower feed seemed to help a little, but not enough to worry about.

I hope I haven't left anything out. I have to be missing something. This even close to working right.

Terrible!

I've followed all the advice I could find online. I RTFM! I watched a dozen YouTube vids. I compiled a list of details to take care of but I absolutely must be missing something. Here's all the things I have done:

+ I have new metal, fresh from the supplier, 6061

+ Cleaned with a SS wire used only for AL

+ .035 wire, 4043 in a spool gun

+ 100% Argon, 15 LPM (I've tried more and less, and I've tried a LOT more and less)

+ put the ground on the piece itself

+ followed the settings on the welder case, tried nearby settings, mostly cooler and slower feed

+ welding in push direction on flat surface

I've burned myself several times and even that doesn't seem to help.

Have a look at the photos and feel free to make fun!

The welds are (black) sooty, not great penetration until suddenly the wire shoots out the other side to the table. I'm also getting white soot on the nozzle and feed gear, somewhat on the work piece too.

So the photos. The welds that look smooth and not AS terrible, that's the back side of piece. ALL my welds look the same.

The material is 1/8 inch, and I've tried dialing the heat down a bit (to D) and I've experimented with the speed from 2.5 to 4.5. The slower feed seemed to help a little, but not enough to worry about.

I hope I haven't left anything out. I have to be missing something. This even close to working right.

.

.