Hoping a physics expert can advise.

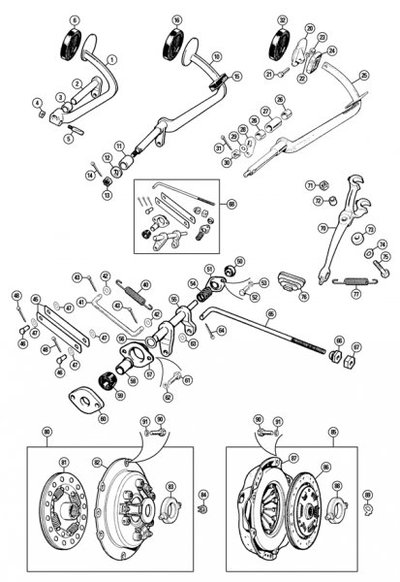

I have a 1959 Morris Minor convertible that I bought in a state of half finished restoration.It had had the engine and box replaced with those from an MG Midget(1275cc).The midget originally had a diaphragm clutch hydraulically operated.The Minor had a coil spring clutch manually operated clutch using rods and levers.I can buy a manual/hydraulic conversion kit but its not cheap and I would prefer if possible to use what I already have.The conversion has been done before but it seems to make the clutch operation quite heavy and on/off in operation.I enclose a diagram of the clutch linkage.Part no:10 is the pedal assembly,41 is the rod that connects the pedal to the lever on shaft 56,the other lever on shaft 56 connects to the clutch adjusting rod 65.I have welded extensions to the 2 levers on shaft 56 and drilled holes in them so I have a variety of positions for the operating rods to attach to in the hope that by increasing the effective leverage I can give more control over clutch operation and also decrease the amount of effort needed at the pedal to move the clutch fork.

My question which (now longer) arm on shaft 56 should be the one that I use to give this effect?I realise I could just try all combinations but if anyone understands the principles properly(its given me a headache)they could point me in the right direction.

Thx

Mick

I have a 1959 Morris Minor convertible that I bought in a state of half finished restoration.It had had the engine and box replaced with those from an MG Midget(1275cc).The midget originally had a diaphragm clutch hydraulically operated.The Minor had a coil spring clutch manually operated clutch using rods and levers.I can buy a manual/hydraulic conversion kit but its not cheap and I would prefer if possible to use what I already have.The conversion has been done before but it seems to make the clutch operation quite heavy and on/off in operation.I enclose a diagram of the clutch linkage.Part no:10 is the pedal assembly,41 is the rod that connects the pedal to the lever on shaft 56,the other lever on shaft 56 connects to the clutch adjusting rod 65.I have welded extensions to the 2 levers on shaft 56 and drilled holes in them so I have a variety of positions for the operating rods to attach to in the hope that by increasing the effective leverage I can give more control over clutch operation and also decrease the amount of effort needed at the pedal to move the clutch fork.

My question which (now longer) arm on shaft 56 should be the one that I use to give this effect?I realise I could just try all combinations but if anyone understands the principles properly(its given me a headache)they could point me in the right direction.

Thx

Mick