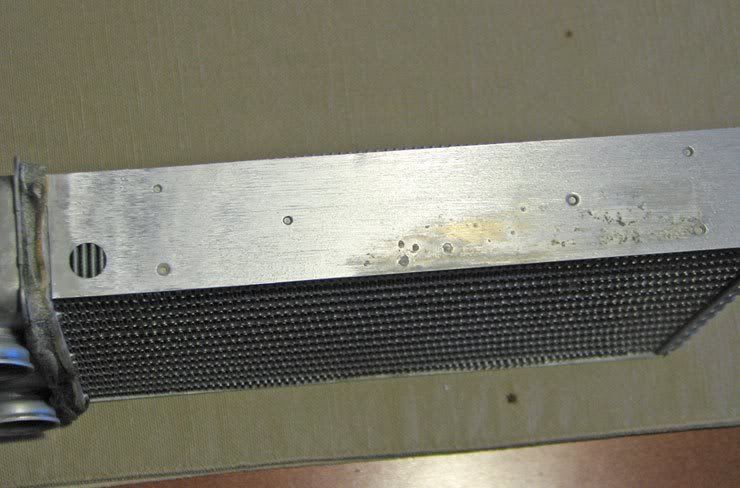

Well yesterday i tried my AC setting on an aluminium car radiator.

(Oxidised yes, tried to clean it but this thing is thin.)

Can anyone tell me if its really me, or is it AC double as bright in contrast with DC ??

I had set my helmet darkness to about 9 and everything was good and dark in the middle of the puddle @ a stainless pipe just minutes ago.

I switch to 40 Amps AC, i flick the switch and i got suprised, welding was about twice as bright and my ceriated 1.6mm tunsten spit its sharp end and balled like hell (ceriated is said it can keep its sharp point), and i got some light spots in my vision, set my helmet to about 11.

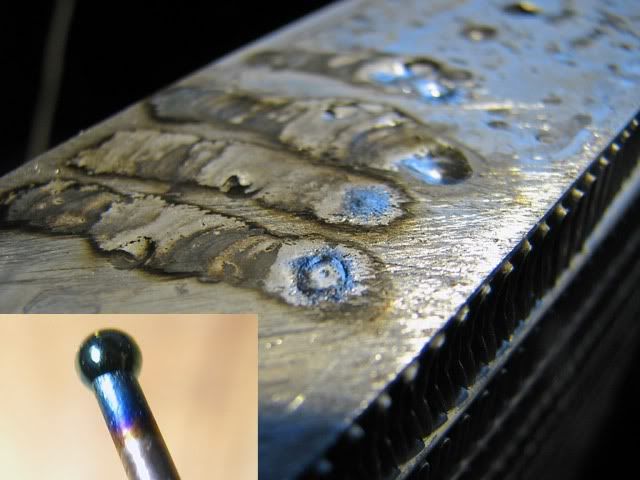

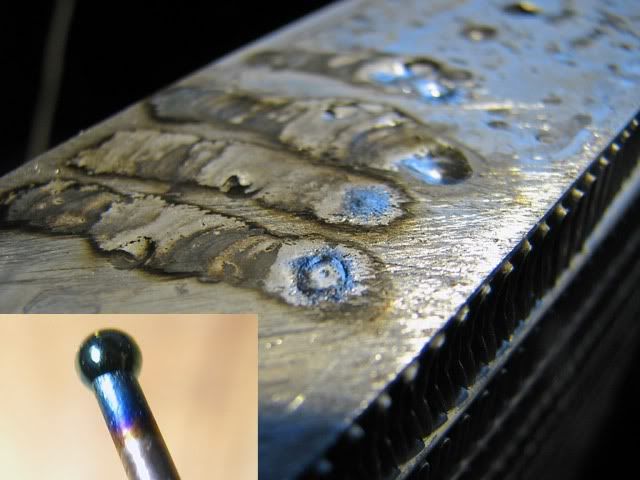

The 1mm alu sheet area didnt opened a hole even at 50-55Amps (no filler). Another spot of interest was the texture of the "welded" surface was like crap (see photo), the puddle as well as the arc while tig'ing, was very scattered and without definition, i've heard that AC alu is like that but that much ?

So -lack of puddle definition - bad texture of the weld -balled ceriated tungsten -and twice as bright are the things i want to have some opinons on! What do u think ?

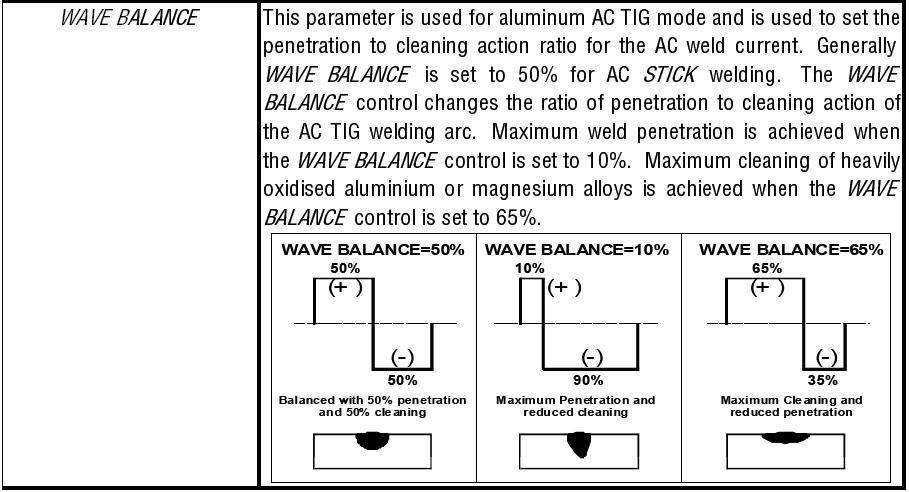

Settings 80-100Hz AC, 70% balance, 50A, 6Lpm tried 7Lpm, 7 Cup, 1.6mm Ceriated.

One suspicion is due to the small thickness of the aluminium the puddle draws oxidised aluminium from the bottom but that much ? The end of each bead was shiny though...

(Oxidised yes, tried to clean it but this thing is thin.)

Can anyone tell me if its really me, or is it AC double as bright in contrast with DC ??

I had set my helmet darkness to about 9 and everything was good and dark in the middle of the puddle @ a stainless pipe just minutes ago.

I switch to 40 Amps AC, i flick the switch and i got suprised, welding was about twice as bright and my ceriated 1.6mm tunsten spit its sharp end and balled like hell (ceriated is said it can keep its sharp point), and i got some light spots in my vision, set my helmet to about 11.

The 1mm alu sheet area didnt opened a hole even at 50-55Amps (no filler). Another spot of interest was the texture of the "welded" surface was like crap (see photo), the puddle as well as the arc while tig'ing, was very scattered and without definition, i've heard that AC alu is like that but that much ?

So -lack of puddle definition - bad texture of the weld -balled ceriated tungsten -and twice as bright are the things i want to have some opinons on! What do u think ?

Settings 80-100Hz AC, 70% balance, 50A, 6Lpm tried 7Lpm, 7 Cup, 1.6mm Ceriated.

One suspicion is due to the small thickness of the aluminium the puddle draws oxidised aluminium from the bottom but that much ? The end of each bead was shiny though...

Last edited:

Thanks!

Thanks!