Well, I went through the entire tutorial (many thanks to all of you who put effort into creating it. It was extremely helpful!) and had my second welding practice today. I had been at Home Depot and was surprised to find some sheet metal, so I bought a piece of 16 gauge (.056 inches thick, according to my caliper), set that up and tried different welding settings.

The welder I'm using (a Dayton 6Z935C, which is definitely a hobby-type welder) has a maximum current of 85 amps, and a minimum of 30 amps. So I interpolated the four settings to 30, 48, 66 and 85 amps for power settings 1 through 4. Thanks to the tutorial, I now really understood what was meant by penetration, so I kept checking the back of the sheet to see how the penetration was going.

I also found that I was making the two beginner mistakes talked about in the tutorial; moving away from the work, so the gap to the torch is too large, and welding too fast. Once I realized this and adjusted, I was able to get very good penetration on a power setting of 3. I was able to get adequate penetration on 2 if I worked very slowly, and I got too much penetration on 4.

By the way, I was surprised that the best wire feed settings for the various power settings were almost the same. This is a very unsophisticated welder and certainly has no automatic wire feed compensation.

The splatter I had with my first welding experience was 90% gone; I assume some splatter is normal. The original splatter must have had something to do with contaminants in the scrap I was welding.

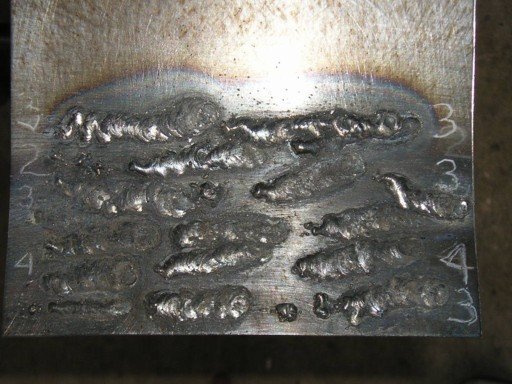

The four pictures show the welds from above and below both straight on and at a low angle, to give some indication of weld height. The numbers represent the power settings. I'd appreciate any comments on the welds and how I can improve.

One concern I had was that even the welds that otherwise looked good seemed rather flat to me. Is this normal when I'm welding thinner stock?

I find that making beads on a sheet is a lot easier than trying to make straight beads! I used a soapstone to draw a straight line as a reference, but I couldn't really see it as I was welding. If fact, I welded over one of my power setting 2 beads because I couldn't really see it, either. I have my helmet set on a shade value of 10. How do you make sure your beads are straight?

Thanks in advance to everyone for their continued help!

The welder I'm using (a Dayton 6Z935C, which is definitely a hobby-type welder) has a maximum current of 85 amps, and a minimum of 30 amps. So I interpolated the four settings to 30, 48, 66 and 85 amps for power settings 1 through 4. Thanks to the tutorial, I now really understood what was meant by penetration, so I kept checking the back of the sheet to see how the penetration was going.

I also found that I was making the two beginner mistakes talked about in the tutorial; moving away from the work, so the gap to the torch is too large, and welding too fast. Once I realized this and adjusted, I was able to get very good penetration on a power setting of 3. I was able to get adequate penetration on 2 if I worked very slowly, and I got too much penetration on 4.

By the way, I was surprised that the best wire feed settings for the various power settings were almost the same. This is a very unsophisticated welder and certainly has no automatic wire feed compensation.

The splatter I had with my first welding experience was 90% gone; I assume some splatter is normal. The original splatter must have had something to do with contaminants in the scrap I was welding.

The four pictures show the welds from above and below both straight on and at a low angle, to give some indication of weld height. The numbers represent the power settings. I'd appreciate any comments on the welds and how I can improve.

One concern I had was that even the welds that otherwise looked good seemed rather flat to me. Is this normal when I'm welding thinner stock?

I find that making beads on a sheet is a lot easier than trying to make straight beads! I used a soapstone to draw a straight line as a reference, but I couldn't really see it as I was welding. If fact, I welded over one of my power setting 2 beads because I couldn't really see it, either. I have my helmet set on a shade value of 10. How do you make sure your beads are straight?

Thanks in advance to everyone for their continued help!