You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

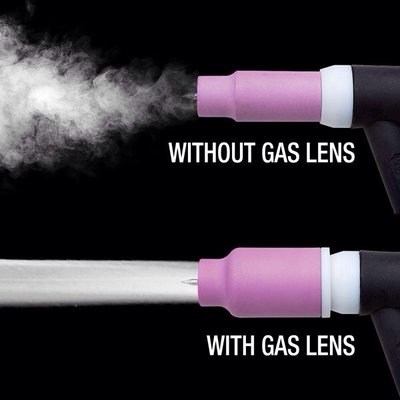

Is there an advantage in using gas lenses?

- Thread starter Noods

- Start date

IT's not like it is going to give you a world of difference.. personally I would just prefer to be a better welder and for sure I would be happy with standard lenses only .... and of course the standard ones are indeed indispensable sometimes because of their smaller size..

.... and of course the standard ones are indeed indispensable sometimes because of their smaller size..

.... and of course the standard ones are indeed indispensable sometimes because of their smaller size..

.... and of course the standard ones are indeed indispensable sometimes because of their smaller size..Jim_gsxr1000

Mechanical Magician

- Messages

- 1,296

It makes a difference to coverage and let's you stick the tungsten out more, I'd always use one where possible !

now tell me.... you are using a standard lens, and what flow are you at? 5lpm? than you switch to a gas lens and you are saying about savings... so again, what flow for the gas lens? again 5Lpm I suppose??... so where is the saving if the output at the regulator is the same.... doesn't make too much sense... I could agree with the better coverage at the same lpm values.. but savings??... I would doubt... I am using both... can't see much difference really....

Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

They do save gas along with a definite weld quality advantage also. The pic illustrates that. The direct gas flow over the pool means lower flow rates can achieve the same results. I can weld Alu / steel at 4lpm indoors with no issues. SS I go up a bit to ensure a decent shiney surface finish. It's a proven fact they do provide a more concentrated coverage over the pool so flow rates can be dropped. If it wasn't then people simply wouldn't buy them at twice the price. I don't see a saving between the standard lens and a ck lens but a lens vs collet bodie there is a big difference. A good test is to try them both out on 6lpm stainless steel both with a number 8 cup. The results from the lens will be easy to see.

Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

If you leave the reg at 5lpm on both then yes your right no saving there. The idea is you can get the same coverage from a lens at a Lower flow rate. Ie you use a collet successfully at 5lpm and the weld is clean. Try a lens at 4lpm. Weld comes out clean??? If so you have just saved 20% of your gas usage simply because of the direct concentrated gas coverage over the pool created by the lens design. A collet body pushes the same volume out but through drilled holes at the side, it's then deflected off the cup walls and forced out in a fashion that is not controlled. The lens the gas is pushed straight down. It doesn't deflect off the hot cup it goes where you need it so less losses and you can drop flow rates.now tell me.... you are using a standard lens, and what flow are you at? 5lpm? than you switch to a gas lens and you are saying about savings... so again, what flow for the gas lens? again 5Lpm I suppose??... so where is the saving if the output at the regulator is the same.... doesn't make too much sense... I could agree with the better coverage at the same lpm values.. but savings??... I would doubt... I am using both... can't see much difference really....

langy

langys rodshop

- Messages

- 6,087

- Location

- London

If you leave the reg at 5lpm on both then yes your right no saving there. The idea is you can get the same coverage from a lens at a Lower flow rate. Ie you use a collet successfully at 5lpm and the weld is clean. Try a lens at 4lpm. Weld comes out clean??? If so you have just saved 20% of your gas usage simply because of the direct concentrated gas coverage over the pool created by the lens design. A collet body pushes the same volume out but through drilled holes at the side, it's then deflected off the cup walls and forced out in a fashion that is not controlled. The lens the gas is pushed straight down. It doesn't deflect off the hot cup it goes where you need it so less losses and you can drop flow rates.

Spot on description Richard

- Messages

- 6,228

- Location

- SW Scotland

Ditto. No lens and about 6lpm. Lens and drop to 4lpm.Spot on description Richard

Thejoker123

Member

- Messages

- 65

- Location

- Staffs

A

As I have done very little tig welding then what is the internal difference between the two?

Ditto. No lens and about 6lpm. Lens and drop to 4lpm.

As I have done very little tig welding then what is the internal difference between the two?

langy

langys rodshop

- Messages

- 6,087

- Location

- London

A

As I have done very little tig welding then what is the internal difference between the two?

If you read a couple of posts above Richard describes the differences or Google gas lense

langy

langys rodshop

- Messages

- 6,087

- Location

- London

now tell me.... you are using a standard lens, and what flow are you at? 5lpm? than you switch to a gas lens and you are saying about savings... so again, what flow for the gas lens? again 5Lpm I suppose??... so where is the saving if the output at the regulator is the same.... doesn't make too much sense... I could agree with the better coverage at the same lpm values.. but savings??... I would doubt... I am using both... can't see much difference really....

All of us that use them are obviously wrong then !!!

God mode restorations

Member

- Messages

- 8,098

- Location

- uk colchester

Well I used a gas lens this weekend courtesy of a friend...and now back on my standard cup 8.and I notice the difference. Hence why I have got my eyes on a set of em. And looking forward to getting them.so yes they do make a noticeable difference. ...

doubleboost

Member

- Messages

- 3,946

- Location

- Newcastle upon Tyne England

I use them all the time

They are just better all round

They are just better all round