You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress 2G Drill

- Thread starter rtbcomp

- Start date

GrahamGKD

Forum Supporter

- Messages

- 1,436

Go on - be a devil.

I know a guy who ran two cars, one quite decent and the other an old banger. When he did an oil change on the good one he put the old oil in the banger.

Well it looks clear enough still but I guess I can afford to change it since I just got an order earlier today

Only thing is - how do you get the old oil out - it's 25 years since I had the machine in bits and the nearest thing I can see to a drain plug looks quite high up on the front? Do I have to tip the head on its side (in which case I'd better wait till a mate comes around)?

GrahamGKD

Forum Supporter

- Messages

- 1,436

If I’m looking at the screw you mean (exposed when the gear speeds are selected) – isn’t that just one of the screws holding the gear selector plate in position? Also, I suspect there may be oil in the machine below that level? Anyway, not a problem for you as yours will clearly be dry when you reassemble it! I guess I can drain mine by releasing the gear selector plate and tilting the machine if needs be. My machine has a little round oil level indicator window on the gear selector plate, just to the rear of the selector itself?

MattF

Forum Supporter

- Messages

- 18,588

- Location

- South Yorkshire

I think I just put Hypoid 90 in mine - it's been in there for about 25 years! Do you think I should change it?

If the bottom cylinder of a Meddings scroll saw that I'm restoring is any indicator, I'd say yes.

Had that thing sat here for months awaiting looking at, and finally decided to strip the cylinder to find out why there seem to be a tight spot on the movement. Still not sure what's causing the binding yet, but the oil in there did definitely leave something to be desired. Around the bottom inch or so was no longer liquid, but rather resembles something akin to chocolate sponge cake.

Had that thing sat here for months awaiting looking at, and finally decided to strip the cylinder to find out why there seem to be a tight spot on the movement. Still not sure what's causing the binding yet, but the oil in there did definitely leave something to be desired. Around the bottom inch or so was no longer liquid, but rather resembles something akin to chocolate sponge cake.rtbcomp

Moderator

- Messages

- 18,548

- Location

- Sheffield UK

I've just taken the side panel off, and that screw I pointed out above is the drain plug.

You have to remove the gear selector. Undo the slot-head screw in the lever, there's a spring and detent ball behind it, then knock the parallel pin out that locates the lever to the shaft. Lever the lever off and lift the panel away. Try to leave the shaft behind otherwise the gear selector will drop off into the gearbox.

The backlash seems part of the design, nothing appears to be loose.

You have to remove the gear selector. Undo the slot-head screw in the lever, there's a spring and detent ball behind it, then knock the parallel pin out that locates the lever to the shaft. Lever the lever off and lift the panel away. Try to leave the shaft behind otherwise the gear selector will drop off into the gearbox.

The backlash seems part of the design, nothing appears to be loose.

Last edited:

GrahamGKD

Forum Supporter

- Messages

- 1,436

Oh, mine doesn't have that boss where your screw is in the casting....This is what I mean

View attachment 26255

I wondered whether it should be lower down, but I can't see anything.

![24022012301[1].jpg 24022012301[1].jpg](https://www.mig-welding.co.uk/forum/data/attachments/23/23727-8cf8becccdf83b0444e16e0cc503fe3a.jpg?hash=jPi-zM34Ow)

The screw on the front of mine is at about the same level though – could be a spooky coincidence....

![24022012300[1].jpg 24022012300[1].jpg](https://www.mig-welding.co.uk/forum/data/attachments/23/23728-2b748d8348743f2c5808fa1d847dab10.jpg?hash=K3SNg0h0Py)

Looking at those pictures I think it's time I gave mine a birthday and cleaned it up a bit (as well as changing the oil)!

Regards the oil level in the window - I've always assumed that the oil was supposed to be somewhere near the top of the window but it is only an assumption mind - maybe you should buy that manual.

GrahamGKD

Forum Supporter

- Messages

- 1,436

I've just taken the side panel off, and that screw I pointed out above is the drain plug..

Thanks RTB, in that case the one on the front of mine must be the equivalent.

The backlash seems, part of the design, nothing appears to be loose.

Yes, I'm sure that's right - when I had mine all those years ago I stripped the whole thing right down. I think I replaced all of the bearings and seals at the time.

GrahamGKD

Forum Supporter

- Messages

- 1,436

What does that cranked lever in the bottom left of your last picture do?

That one locks the drilling head to its vertical position (i.e. stops the spring returning it) - quite handy for setting the depth of counter bores and the like. I'm guessing you don't have one of those then? I wonder which of our machines is older?

I presume you came across two little phosphor bronze dogs (not sure if that is the right name?) on the gear selector - when I got hold of mine those were so worn the gears were on the cusp of selecting even when disengaged on the lever. The company I was working for threw the machine out because the gears were jangling all of the time. It was in bits outside the back of the factory when I spotted it.

rtbcomp

Moderator

- Messages

- 18,548

- Location

- Sheffield UK

Just had a close look inside the gearbox.

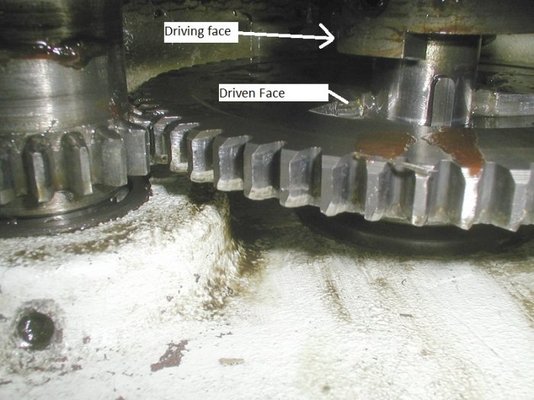

The backlash is a feature of the design, but in mine where the driving and driven halves of the clutch engage the driven side is a bit mangled. I guess this is a result of the drive being taken up with a clunk. You're doing the right thing by turning the chuck back before switching on.

The backlash is a feature of the design, but in mine where the driving and driven halves of the clutch engage the driven side is a bit mangled. I guess this is a result of the drive being taken up with a clunk. You're doing the right thing by turning the chuck back before switching on.

rtbcomp

Moderator

- Messages

- 18,548

- Location

- Sheffield UK

The gear selector on mine is fibre, as is the top gear on the layshaft. If your selector had bronze shoes I would guess your is older, assuming that machine development means reducing costs!

I do have that lever, but wasn't sure what it did.

I do have that lever, but wasn't sure what it did.

GrahamGKD

Forum Supporter

- Messages

- 1,436

The gear selector on mine is fibre, as is the top gear on the layshaft. If your selector had bronze shoes I would guess your is older, assuming that machine development means reducing costs!

As far as I can remember there are no fibre bits in mine (and I think I would remember something like that). Mine is a bit rattly with the gears engaged with the higher belt speeds - perhaps they went to fibre to reduce noise?

rtbcomp

Moderator

- Messages

- 18,548

- Location

- Sheffield UK

There are two dogs 180 deg. apart, giving two contact surfaces. Due to the dimensions of the dogs there is about 90 deg. backlash.

The face you can see on the driving dog contacts the driven member when running in reverse.

Personally I would have made them a tighter fit to virtually eliminate the backlash and thus reduce the hammering that the driven dog has obviously received.

The face you can see on the driving dog contacts the driven member when running in reverse.

Personally I would have made them a tighter fit to virtually eliminate the backlash and thus reduce the hammering that the driven dog has obviously received.

MattF

Forum Supporter

- Messages

- 18,588

- Location

- South Yorkshire

There are two dogs 180 deg. apart, giving two contact surfaces. Due to the dimensions of the dogs there is about 90 deg. backlash.

Makes you wonder what's running through the minds of designers on occasion, doesn't it.

Personally I would have made them a tighter fit to virtually eliminate the backlash and thus reduce the hammering that the driven dog has obviously received.

Aye, that would be the more sensible design option. Going for three or four tighter meshing teeth would be another option. Is there no way you can adapt the clutch mechanism to remedy its design quirk?