prepman

Forum Supporter

- Messages

- 2,770

- Location

- Gwynedd UK

For interest (or not).....Levelling is not a true term, but it's the one widely used for bed alignment.

Don't normally have an issue with producing accidental tapers (5 thou' ver 9"). But making an arbor for the Senior mill has been a bumpy journey, mainly by cutting corners.

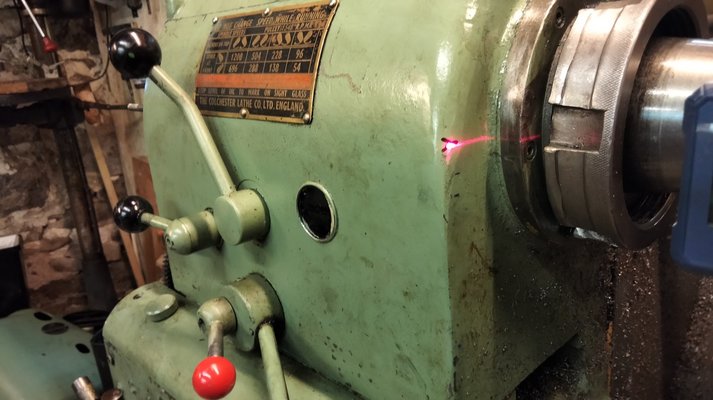

On my Mk1 Student there are no headstock adjustments. The head unit was factory ground to give fit. The recommended action to settle the headstock down after calamitous event, is to slacken off the 5 socket screws and then re-tighten.

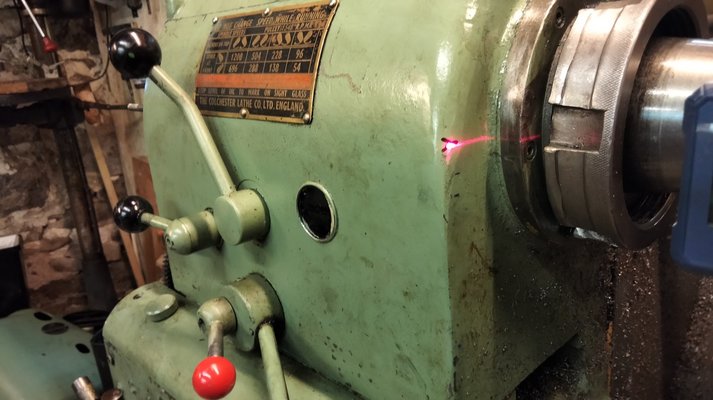

Have done this a number of times in the past with varying results. Anyway decided to check for bed twist. Used a white spirit filled test tube previously, but decided to use a laser level to see if it was a better way......It worked, but again not conclusive if the headstock is slightly

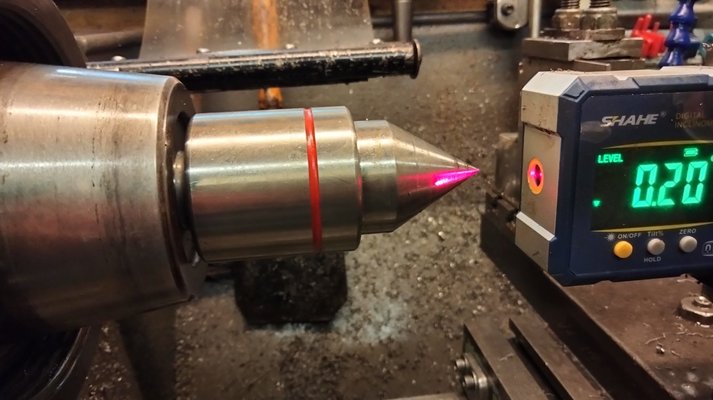

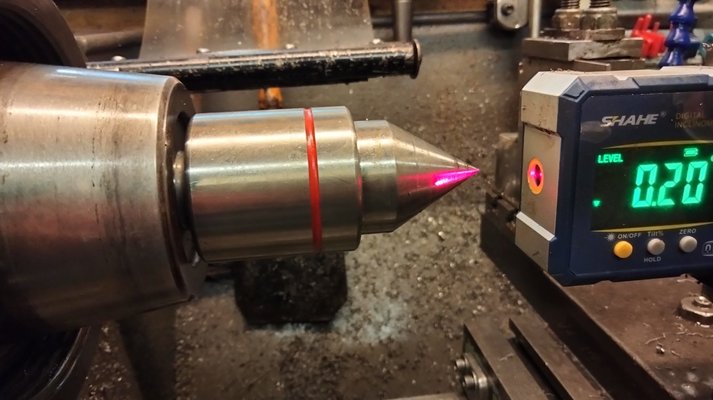

The story so far. Put centre in headstck and it spun true, so point is definiely centre. Attached the laser to the toolpost and aligned it vertically then traversed across to check horizontally aligned. Then ran the saddle to end of bed and rechecked/adjusted until centred at both points. Traversed out near headstock and marked laser on headstock, then from the end of the bed.. The theory is that any shift can only be due to twist, not even bed wear. I think I'm correct but don't mind being proved wrong. Obviously not vehemently.

Don't normally have an issue with producing accidental tapers (5 thou' ver 9"). But making an arbor for the Senior mill has been a bumpy journey, mainly by cutting corners.

On my Mk1 Student there are no headstock adjustments. The head unit was factory ground to give fit. The recommended action to settle the headstock down after calamitous event, is to slacken off the 5 socket screws and then re-tighten.

Have done this a number of times in the past with varying results. Anyway decided to check for bed twist. Used a white spirit filled test tube previously, but decided to use a laser level to see if it was a better way......It worked, but again not conclusive if the headstock is slightly

The story so far. Put centre in headstck and it spun true, so point is definiely centre. Attached the laser to the toolpost and aligned it vertically then traversed across to check horizontally aligned. Then ran the saddle to end of bed and rechecked/adjusted until centred at both points. Traversed out near headstock and marked laser on headstock, then from the end of the bed.. The theory is that any shift can only be due to twist, not even bed wear. I think I'm correct but don't mind being proved wrong. Obviously not vehemently.