You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

- Messages

- 24,048

- Location

- Birmingham

A friend of mine makes the odd sign

Dr.Al

Forum Supporter

- Messages

- 2,773

- Location

- Gloucestershire, UK

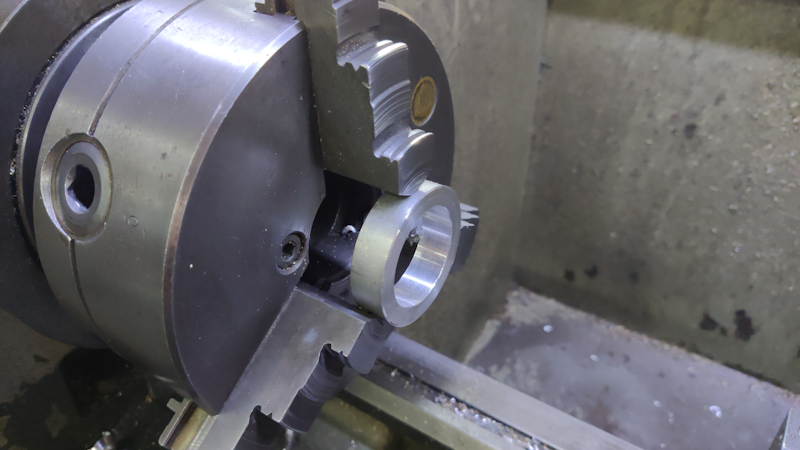

Today I made a simple aluminium ring with a 36.9 mm through hole:

I've got a (rather expensive, but generally very good) oil can, but the oil seal doesn't seem very well thought out. Having made the ring, I mounted the body of the oil can in the lathe and got it running true with a bearing tool in the tool post (photo taken after swapping the bearing tool for a cutting tool, obviously):

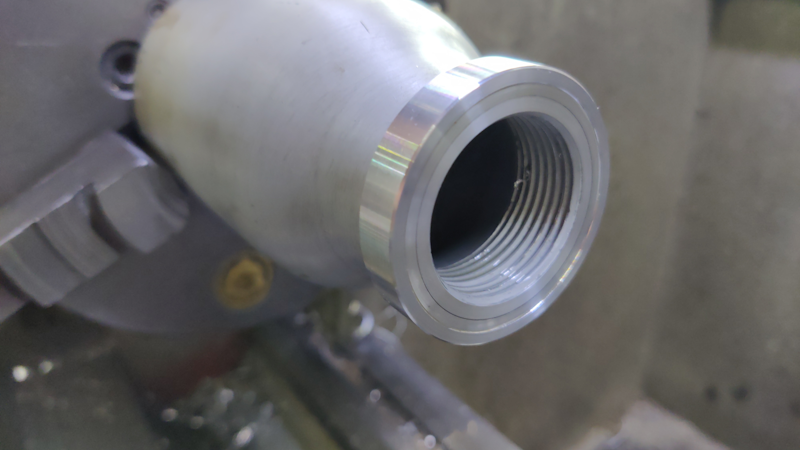

I then skimmed the first 10 mm of the outside down to 36.9 mm (it was 37 mm at the rim, tapering up at about 3° included angle):

A bit of superglue joined the two bits together:

Once the superglue had been left for 5 minutes or so to do its thing, I took some gentle cuts to machine the face to length, machine the outside and also to cut a small rebate on the face to match the diameter of the stock seal:

A quick test-fit before removing it from the lathe seemed a good idea:

The oil seal still bears on the rim of the can itself, but the aluminium disk supports the outside better and hopefully that'll result in fewer damaged seals.

I've got a (rather expensive, but generally very good) oil can, but the oil seal doesn't seem very well thought out. Having made the ring, I mounted the body of the oil can in the lathe and got it running true with a bearing tool in the tool post (photo taken after swapping the bearing tool for a cutting tool, obviously):

I then skimmed the first 10 mm of the outside down to 36.9 mm (it was 37 mm at the rim, tapering up at about 3° included angle):

A bit of superglue joined the two bits together:

Once the superglue had been left for 5 minutes or so to do its thing, I took some gentle cuts to machine the face to length, machine the outside and also to cut a small rebate on the face to match the diameter of the stock seal:

A quick test-fit before removing it from the lathe seemed a good idea:

The oil seal still bears on the rim of the can itself, but the aluminium disk supports the outside better and hopefully that'll result in fewer damaged seals.

Munkul

Jack of some trades, Master of none

- Messages

- 7,748

- Location

- Cumbria

First batch of TIG torch holders deburred, folded and assembled tonight. I made a folding jig for the awkward parts and it works really well. Also works for the really short leg on the straight front plate, i can cleanly fold a 7mm leg on 2mm stainless here which I'm pretty pleased about.

30 more to go...

30 more to go...

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Nice bit of turning what will you use when the glue deteriorates ?Today I made a simple aluminium ring with a 36.9 mm through hole:

View attachment 444407

I've got a (rather expensive, but generally very good) oil can, but the oil seal doesn't seem very well thought out. Having made the ring, I mounted the body of the oil can in the lathe and got it running true with a bearing tool in the tool post (photo taken after swapping the bearing tool for a cutting tool, obviously):

View attachment 444408

I then skimmed the first 10 mm of the outside down to 36.9 mm (it was 37 mm at the rim, tapering up at about 3° included angle):

View attachment 444411

A bit of superglue joined the two bits together:

View attachment 444412

Once the superglue had been left for 5 minutes or so to do its thing, I took some gentle cuts to machine the face to length, machine the outside and also to cut a small rebate on the face to match the diameter of the stock seal:

View attachment 444413

A quick test-fit before removing it from the lathe seemed a good idea:

View attachment 444414

The oil seal still bears on the rim of the can itself, but the aluminium disk supports the outside better and hopefully that'll result in fewer damaged seals.

I use the empty washed out squeezy 150 ml hair dye bottles our Ukrainian gal uses when hiding the grey mare on her head . If I drop one it does not damage them .

Discovered this morning that the local ladies hair dresser has a few most weeks

Dr.Al

Forum Supporter

- Messages

- 2,773

- Location

- Gloucestershire, UK

Dunno. Replace it with Loctite 603 probably (that's what I normally do with metal-to-metal gluing). It shouldn't matter too much if the glue does fail: as the aluminium sits on a reduced diameter bit with a (small) shoulder, it shouldn't go anywhere even if the glue fails. The oil seal is still formed by the o-ring thing pressing against the rim of the bottle. If the aluminium bit becomes loose, it'll still serve the purpose of stopping the o-ring from rolling over the edge.Nice bit of turning what will you use when the glue deteriorates ?

Misterg

Member

- Messages

- 1,681

- Location

- North Wales

I was changing the water pump on my car and the little elbow on the inlet pipe had rusted to nothing. It should look like this:

But mine looked like this:

A new inlet pipe is about £90, and several days away, so...

After drilling out the remains of the steel elbow, I was left with a hole that would take an M12 tap.

Lump of brass in the lathe, drilled part way through, turned down one end and cut an M12 thread on it. Also machined down a commercial hose barb that I happened to have.

The punch mark shows the right place to drill so that the elbow is 'clocked' right when the threaded bit is screwed into the inlet pipe.

Set up in the 4 jaw to make a hole for the hose barb:

Drilled & bored to suit

Prepared for silver soldering - my little blowlamp needs all the help it can get.

Silver soldered and cleaned up a bit:

Job done:

But mine looked like this:

A new inlet pipe is about £90, and several days away, so...

After drilling out the remains of the steel elbow, I was left with a hole that would take an M12 tap.

Lump of brass in the lathe, drilled part way through, turned down one end and cut an M12 thread on it. Also machined down a commercial hose barb that I happened to have.

The punch mark shows the right place to drill so that the elbow is 'clocked' right when the threaded bit is screwed into the inlet pipe.

Set up in the 4 jaw to make a hole for the hose barb:

Drilled & bored to suit

Prepared for silver soldering - my little blowlamp needs all the help it can get.

Silver soldered and cleaned up a bit:

Job done:

iNf

Forum Supporter

- Messages

- 724

- Location

- Hereford, England

I've got a few of those around the workshop, very handy for oil, soluble cutting fluid etc. If they can withstand the chemicals that they contain, a bit of oil should be no problemNice bit of turning what will you use when the glue deteriorates ?

I use the empty washed out squeezy 150 ml hair dye bottles our Ukrainian gal uses when hiding the grey mare on her head . If I drop one it does not damage them .

Discovered this morning that the local ladies hair dresser has a few most weeks

oldbikedavey

Member

- Messages

- 1,995

- Location

- London, England

Mostly, I've developed, sheared out, folded, and tolerably TIG welded up a semi-prototype aluminium battery tray for a particularly bespoke Norvin that I'm building for someone.

Space is in extremely short supply....

Space is in extremely short supply....

- Messages

- 13,490

- Location

- England

Knocked this little model linisher up, odd 5 mins here and there...

Little get well present for my apprentice.

She's having a pretty rough time at the moment, so thought I'd make her a model of her 'favourite' piece of workshop equipment.

Favourite, as in scared of it after doing her nails on it one day

Little get well present for my apprentice.

She's having a pretty rough time at the moment, so thought I'd make her a model of her 'favourite' piece of workshop equipment.

Favourite, as in scared of it after doing her nails on it one day

Memmeddu

Member

- Messages

- 5,808

- Location

- Italia Sardegna

I've decided to work on my little punto for 10 minutes...

Well it was supposed to last 10 minutes.

So the only job which shouldn't take more than 10 minutes, it turn out to be a nightmare.

Spark plug broken in its seat.

I've had to accurately remove any single ceramic fragment prior to replace it preventing a disaster.

Imagine the amount of damage a little piece of ceramic can do if going inside the cylinders

Munkul

Jack of some trades, Master of none

- Messages

- 7,748

- Location

- Cumbria

I know that pain. On paper, slot profiling steel with a small end mill works great... in practice not so great

If you're patient enough maybe... but I always try to push the DOC and feed too hard

If you're patient enough maybe... but I always try to push the DOC and feed too hard

Melvyn Best

Member

- Messages

- 1,990

- Location

- Cambridge

That was a common problem on some Fords that had tempered seats , also VW air cooled engines if Champion spark plugs had been fittedView attachment 444561

I've decided to work on my little punto for 10 minutes...

Well it was supposed to last 10 minutes.

So the only job which shouldn't take more than 10 minutes, it turn out to be a nightmare.

Spark plug broken in its seat.

I've had to accurately remove any single ceramic fragment prior to replace it preventing a disaster.

Imagine the amount of damage a little piece of ceramic can do if going inside the cylinders

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Ha ha did that a couple of days ago, brand new 8mm extra long aluminium cutter, forgot to disable the lead out transition so it did a nice wee arc into the vice and snapped like a carrot

JMS1972

Member

- Messages

- 1,197

- Location

- NW Leicestershire, UK

Stefan Gotteswinter did a YouTube video on cutting sheet recently he suggested doing many light cuts with fast feed rates.I know that pain. On paper, slot profiling steel with a small end mill works great... in practice not so greatIf you're patient enough maybe... but I always try to push the DOC and feed too hard

He recommended using end mills with a slight corner chamfer and keeping depth of cut below the chamfer height.

Dramatically reduces endmill wear.

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,359

- Location

- Sevenoaks, UK

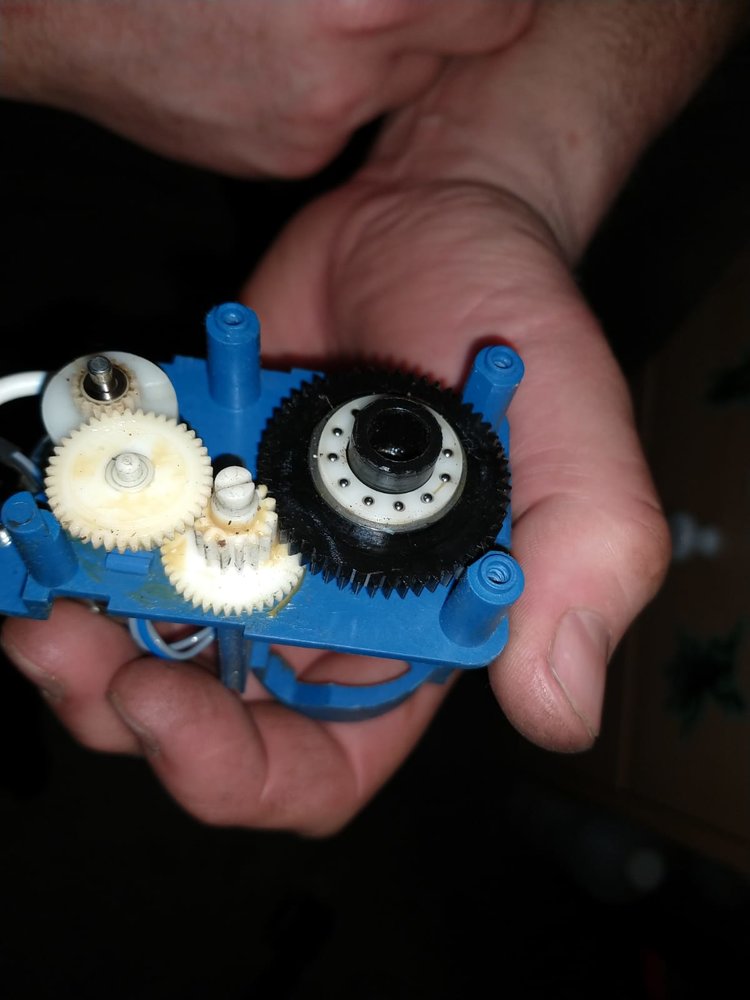

You know when you have this idea, don't think it through fully, then have a sudden realisation you're an idiot?

I have a whole bunch of redundant 24VAC valve actuators. They have an M8 thread for a little aluminium bracket that attaches to the 4-port valve. The valves get stiff, the aluminium bracket shears and they bin the whole lot. Perfectly useable for "something". With a quick mod they'll happily run along a bit of M8 studding at low speed in fwd/rev as they have a 3 wire cable. Been trying to think of a use for them. This with the lid off:

So...as they're M8 I figured get my lad to reproduce the final gear with the M8 centre thread upped to M10:

Test print on the right looks pretty good:

If I now say this was for a rotator device to turn an M10 bolt whilst I weld it, maybe someone can see the issue?

I have a whole bunch of redundant 24VAC valve actuators. They have an M8 thread for a little aluminium bracket that attaches to the 4-port valve. The valves get stiff, the aluminium bracket shears and they bin the whole lot. Perfectly useable for "something". With a quick mod they'll happily run along a bit of M8 studding at low speed in fwd/rev as they have a 3 wire cable. Been trying to think of a use for them. This with the lid off:

So...as they're M8 I figured get my lad to reproduce the final gear with the M8 centre thread upped to M10:

Test print on the right looks pretty good:

If I now say this was for a rotator device to turn an M10 bolt whilst I weld it, maybe someone can see the issue?