A standard transformer-based arc welder nearly always produces AC output, whether it be the cheapest buzz box or the more highly regarded Oxford type oil immersed arc welders. I'm going to try adding rectification to my arc welders, to produce a DC output. The resultant DC output should have at least two uses:

1. DC arc welding of steel. Many people say it's smoother than AC.

2. TIG welding of steel, when AC is said not to work, and I'm sure that's right.

Plus use as a battery charger, perhaps. It should be quite easy to get the voltage of about 48 volts down to about 14 volts for the purpose of charging a car battery.

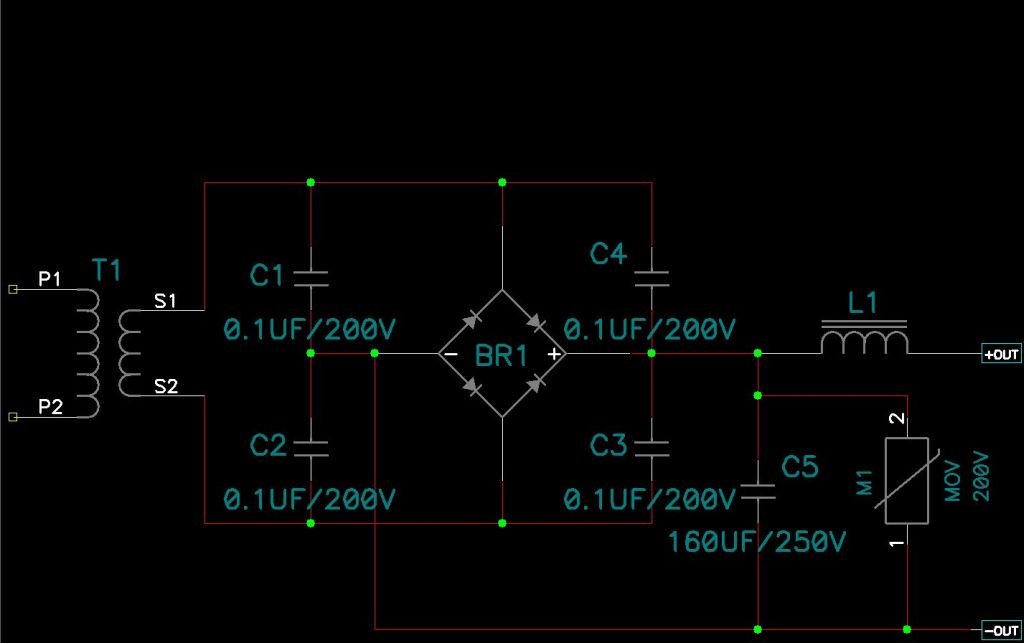

This should not be difficult. On another thread, I suggested I could simply add a 50p bridge rectifier, rated at about 35A or 50A. With such a small rectifier, I'd need to keep the arc welder on it's lowest setting for DC applications but that's OK, as I'm mainly interested in DC for arc and TIG welding of thin sheet steel and other small scale work, which needs only low power.

thesnooer responded as follows:

I agree it's desirable to use higher-rated diodes or a larger bridge rectifier but why should a 35A or 50A bridge rectifier overheat, if the arc welder is kept turned down to 30 or 35A? I can add a large heat sink and fan.

1. DC arc welding of steel. Many people say it's smoother than AC.

2. TIG welding of steel, when AC is said not to work, and I'm sure that's right.

Plus use as a battery charger, perhaps. It should be quite easy to get the voltage of about 48 volts down to about 14 volts for the purpose of charging a car battery.

This should not be difficult. On another thread, I suggested I could simply add a 50p bridge rectifier, rated at about 35A or 50A. With such a small rectifier, I'd need to keep the arc welder on it's lowest setting for DC applications but that's OK, as I'm mainly interested in DC for arc and TIG welding of thin sheet steel and other small scale work, which needs only low power.

thesnooer responded as follows:

i cant see a small bridge rectifier working for welding even if the amperage is within you spec as the heat generated will probably destroy it.

you would be better off buying 4 diodes that can be mounted on a heatsink and make your own rectifier with a bigger tolerance

I agree it's desirable to use higher-rated diodes or a larger bridge rectifier but why should a 35A or 50A bridge rectifier overheat, if the arc welder is kept turned down to 30 or 35A? I can add a large heat sink and fan.