I am not sure which orientation to print the above.

Its from thingiverse.

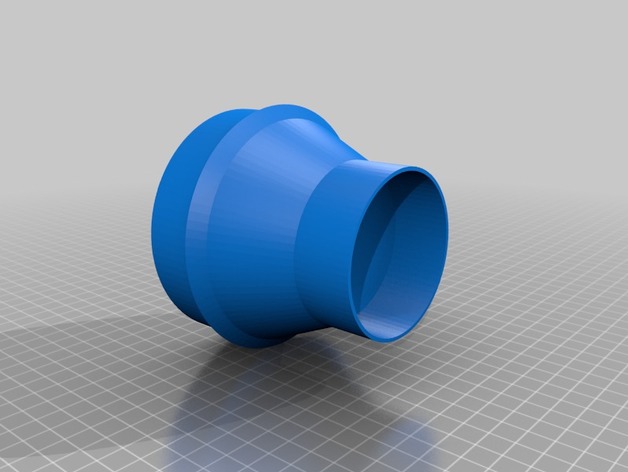

2.5 to 4 inch Adapter for Dewalt Table Saw by dimi523

Dust collection adapter for Dewalt DWE7491 table saw 2 1/2 inch port to a 4 inch hose.

Yeah cheers for the detailed reply.@ukracer - I am not an expert but if I was drawing something similar I would draw the profile at a suitable distance from the vertical axis to include the required shell thickness then revolve it around said vertical axis. And then print it the other way up, as previously described, to reduce overhangs and eliminate supports.

Edit: I've just looked at it on Thingiverse and the originator shows it printing the other way up.

View attachment 433952

You haven't seen me using fusion....lolI'd print large diameter on bed, less chance of it falling over. Strength may be an issue though as you point out.

For the design, do as @Bladevane says, draw the profile the radius from the vertical axis and use dimensions to constrain:

Draw a construction line vertically on the vertical axis, draw the profile in approv the correct place (vertical line , diagonal, vertical line - forget the blip for now).

Now offset that profile by 5mm, connect the top and bottom with short lines.

Next add your dimensions, 2" from outside of profile to axis construction line at the bottom and 1.25" from inside profile at the top.

You'll now need to dimension the heights of each section, and add the blip.

Now revolve the profile around the construction axis.

If you need to adjust the fit just tweak dimensions in the sketch.

The whole process should take no more than a minute.

It's extraction on a dewalt saw bench.Two things to consider:

If this is to have stuff flowing through it, the inside, where the fluid flows, benefits from being smoother rather than rougher. Hence, a print orientation which maximises this would seem to be preferable.

Second, I wondered if the taper angle was important. This (https://www.pumpsandsystems.com/tapered-rubber-expansion-joints), just as a starter contribution on the subject, implies that the taper is too steep.

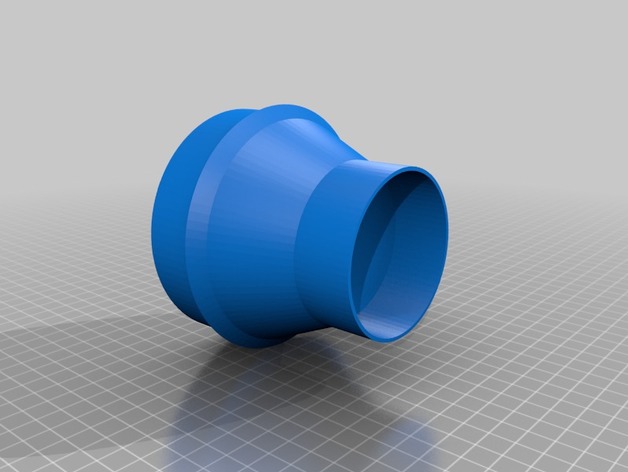

Cheers chap. I will still have a go myself but will use yours to print one in ABS pro.Here I was in Fusion for something else, this is a straight copy just at 5mm thick (you might find it'll be so much stiffer it might not slide on the tool side easily now though, depending on the clearance)

Lol. No mate . I had to get the wife dressed before I can start the print off.And one that should flow better and probably not make as much noise doing it:

View attachment 433996

Hopefully you're not already printing, a courier came right as I was sending this

Cheers chap. I will still have a go myself but will use yours to print one in ABS pro.