- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vrtical table mill attachments

- Thread starter Cheesie

- Start date

Ooo, that’s rather neat. Milling machines tend to take up quite a bit of space, and all the add to lathe ones, as you say tend to be a bit small...

An Amolco type bigger brother would probably suite you, but I don’t know of anything. Maybe you should have a google around, look for something with a round pillar that you could make a lathe way shaped foot for - sort of make your own?

An Amolco type bigger brother would probably suite you, but I don’t know of anything. Maybe you should have a google around, look for something with a round pillar that you could make a lathe way shaped foot for - sort of make your own?

RobCox

Member

- Messages

- 547

- Location

- Cambridge, UK

I bought one of these when I had (still have - just doesn't get used) a minilathe:

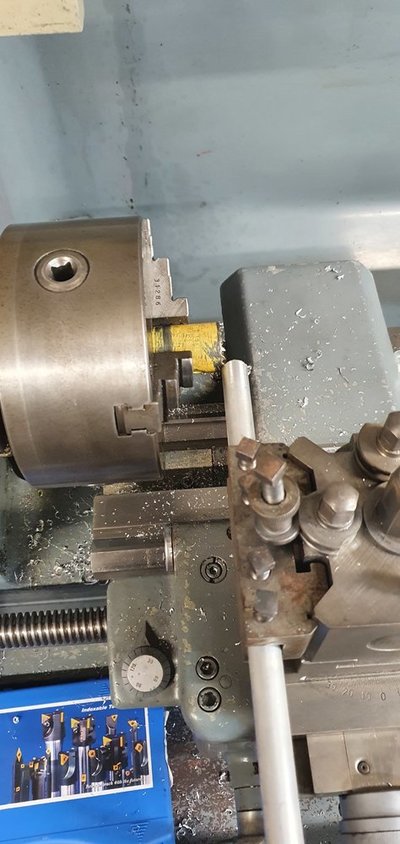

The idea was to do some milling, but the whole arrangement turned out not to be very rigid, not enough travel, awkward to set up, so I bought a milling machine. I nearly sold this a couple of years ago but the potential buyer lost interest / pulled out and I'd already got seller's remorse so I hung on to it. I've since put it to good use on my M300 machining a threading follower for another lathe thats still WIP:

All cast iron construction, very rigid. I think it's a modification of a type designed to fit a Myford lathe. Bought from Warco. £124 now, but out of stock at the mo.

The idea was to do some milling, but the whole arrangement turned out not to be very rigid, not enough travel, awkward to set up, so I bought a milling machine. I nearly sold this a couple of years ago but the potential buyer lost interest / pulled out and I'd already got seller's remorse so I hung on to it. I've since put it to good use on my M300 machining a threading follower for another lathe thats still WIP:

All cast iron construction, very rigid. I think it's a modification of a type designed to fit a Myford lathe. Bought from Warco. £124 now, but out of stock at the mo.

I plan to get a mill at some point I'm running out of room but if the right one came up for sale I'd get it, until then just thinking of more ways to use what I haveLike Rob, I have one. It came with my lathe but I’ve never used it (‘cos I have two milling machines). Rob’s use as a cutter/tool holder/whatever on the lathe looks like a novel use for it! Not quite s QCTP but certainly a quick adjust tool post! And more rigid than a lot of the QCTPs on many hobby lathes!

gaz1

Member

- Messages

- 20,541

- Location

- westyorkshire

i wouldnt build or buy a vertical attachment for the lathe

if i had to build one id rather make the milling machine and you can do it

however you can mill rather well with just your lathe and your cross slide with the tool in your head and an angle plate for long pieces

if i had to build one id rather make the milling machine and you can do it

however you can mill rather well with just your lathe and your cross slide with the tool in your head and an angle plate for long pieces

gaz1

Member

- Messages

- 20,541

- Location

- westyorkshire

as goes for a milling machine depends on which way you want to go

theres the dore westbury way or the simple head via the atlas milling machine the sharp milling machine uses the same head to a degree

there is also a concrete way as well, note a horizontal mill can be changed to a vertical using the atlas head

theres the dore westbury way or the simple head via the atlas milling machine the sharp milling machine uses the same head to a degree

there is also a concrete way as well, note a horizontal mill can be changed to a vertical using the atlas head

Thinking a centec or something like it with a quill, needs to have a quillas goes for a milling machine depends on which way you want to go

theres the dore westbury way or the simple head via the atlas milling machine the sharp milling machine uses the same head to a degree

there is also a concrete way as well, note a horizontal mill can be changed to a vertical using the atlas head

Indeed it does - centec no good though, needs a pillar you can make a mount for.Thinking a centec or something like it with a quill, needs to have a quill

I've got a Myford vertical slide that I made a new base plate to fit my lathe. Remove the compound slide to use it - not too bad for rigidity - at least, I've not noticed it bouncing around when all locked down. doesn;t get as much use as I also have a small mill too.

As an aside - you can get the same effect on that tube by two angled cuts in/with a saw.

As an aside - you can get the same effect on that tube by two angled cuts in/with a saw.

Agroshield

Member

- Messages

- 6,394

Have a look on YT for a Japanese guy called 'Swap Lamp'. He has a recent video where he converts the lathe's compound slide into a vertical slide. It is an idea I had never seen before.

There are not many vertical slides for lathes about. The Myford (and copies) is by far the most common. Occasionally a Boxford one comes up but they are big money.

There are not many vertical slides for lathes about. The Myford (and copies) is by far the most common. Occasionally a Boxford one comes up but they are big money.

brightspark

Member

- Messages

- 41,587

- Location

- yarm stockton on tees

could have bought a myford one in good nick for 50 quid from autojumble but dont need one

Look like handy machines to have and not too big eitherI have a 2B (with a riser block and power feed). The little Raglan still gets used for lots of jobs (that can be fitted on it).

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,560

- Location

- France, Brittany.

You're missing an 'e'.

Mini Milling Machine Vertical Milling/Drilling Machine | eBay

Find many great new & used options and get the best deals for Mini Milling Machine Vertical Milling/Drilling Machine at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

Milling Machine made by Warco | eBay

Find many great new & used options and get the best deals for Milling Machine made by Warco at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

I'd like something a little bigger than both of them I've watched a few on ebay delivery is a problem for me

Mini Milling Machine Vertical Milling/Drilling Machine | eBay

Find many great new & used options and get the best deals for Mini Milling Machine Vertical Milling/Drilling Machine at the best online prices at eBay! Free delivery for many products.www.ebay.co.uk

Milling Machine made by Warco | eBay

Find many great new & used options and get the best deals for Milling Machine made by Warco at the best online prices at eBay! Free delivery for many products.www.ebay.co.uk

Maker

Most folk just call me; Orange Joe

- Messages

- 10,687

- Location

- Keeler crater

Brilliant! I'd been trying to come up with a way to make a similar part, I was thinking it would be a big unbalanced faceplate job, or thread a full bore, cut a segment out of it and braze it to a body. Your way looks much more convenient.I bought one of these when I had (still have - just doesn't get used) a minilathe:

View attachment 372560

The idea was to do some milling, but the whole arrangement turned out not to be very rigid, not enough travel, awkward to set up, so I bought a milling machine. I nearly sold this a couple of years ago but the potential buyer lost interest / pulled out and I'd already got seller's remorse so I hung on to it. I've since put it to good use on my M300 machining a threading follower for another lathe thats still WIP:

View attachment 372562

All cast iron construction, very rigid. I think it's a modification of a type designed to fit a Myford lathe. Bought from Warco. £124 now, but out of stock at the mo.

Kram

Member

- Messages

- 8,379

- Location

- Sussex

Another option is to buy one of the better drill press compound slides and make a vertical mount for it/big angle plate

Mine, I used a cheap drummond M cross slide and saddle.

Note you will need a suitable vice. The vice fixed jaw size can limit your travel if too big. The weight of the arrangement can also make the dovetails lift at the back if it overhangs too much, ideally the weight needs to be back a bit so it can be centered over slide.

A lathe can be exceptionally rigid for milling if the Z is locked and supported. You may also want a boring head for stuff like your example where theres not a suitable holesaw.

A face mill is also fun.

Your junk corner is about twice the total size of my shed

Mine, I used a cheap drummond M cross slide and saddle.

Note you will need a suitable vice. The vice fixed jaw size can limit your travel if too big. The weight of the arrangement can also make the dovetails lift at the back if it overhangs too much, ideally the weight needs to be back a bit so it can be centered over slide.

A lathe can be exceptionally rigid for milling if the Z is locked and supported. You may also want a boring head for stuff like your example where theres not a suitable holesaw.

A face mill is also fun.

Your junk corner is about twice the total size of my shed

Arc Tourist

Member

- Messages

- 5,053

- Location

- Wales

Years ago, I was able to find one of the rare Boxford type just before I bought my mill. It was expensive then, but I haven't used it since acquiring the mill.........................................

There are not many vertical slides for lathes about. The Myford (and copies) is by far the most common. Occasionally a Boxford one comes up but they are big money.