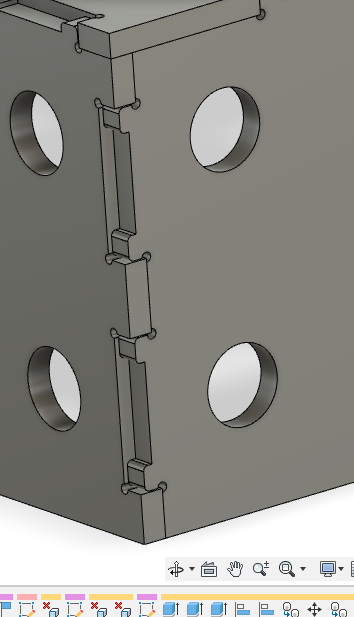

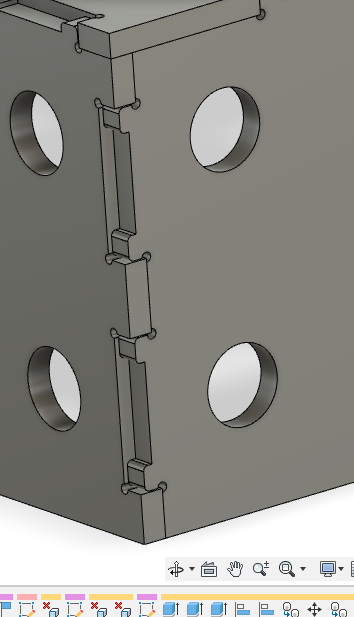

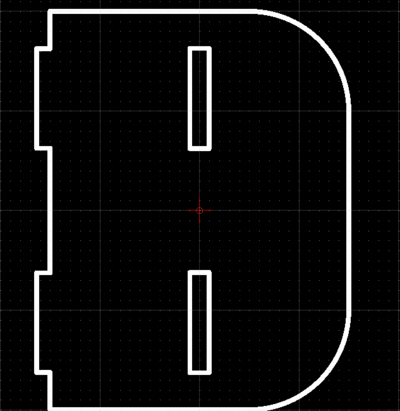

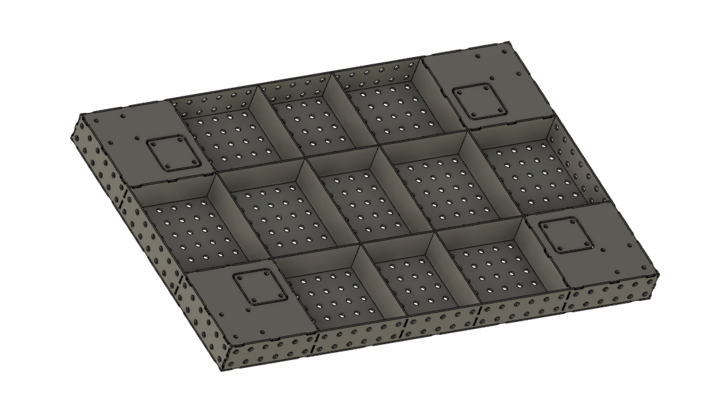

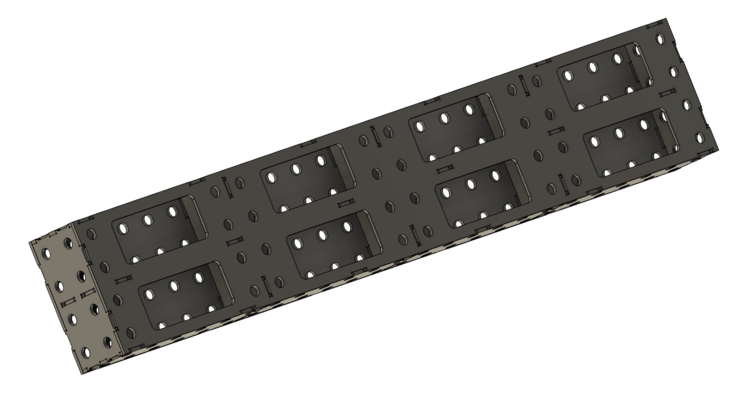

Hi, I'm 'designing' a welding table in fusion 360 using the tab and slot design, how much tolerance should i leave between the tab and the slot? I imagine if i have a 30x5 slot and a 30x5 tab I'll have difficulty fitting everything up? For now i've made the tabs 30mm long and the slots 30,1 mm long, no idea if this enough, too little or too much.

Anyone have experience with this?

Anyone have experience with this?

.

.