You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sandrail Engine swap

- Thread starter Wightsparks

- Start date

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

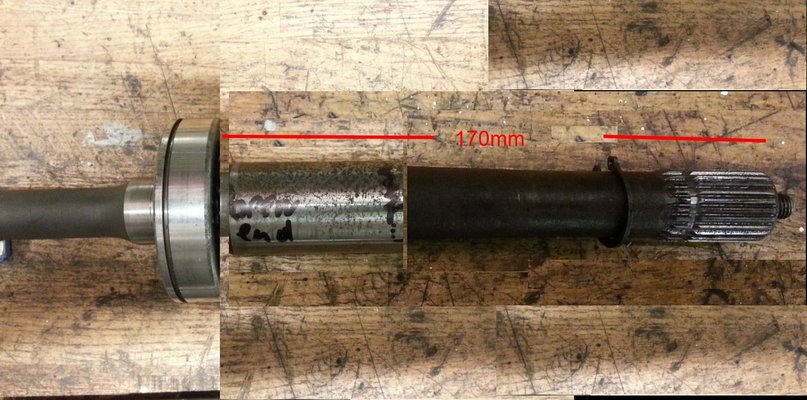

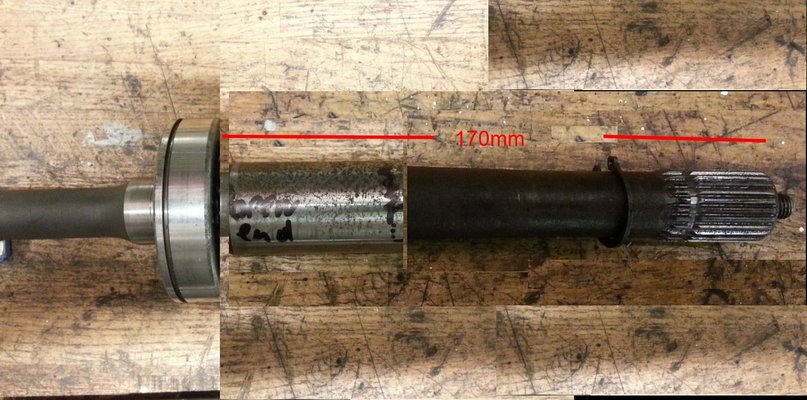

As I am still waiting for the template to arrive I have turned my attention to the shafts. Only to find once again that my plans for welding are thwarted by heat distortion. The plan was to join these two MX5 bits

Like this (chopping the cogs off)

and this VW and MX5 female spline bit

like this

So that they could handily slide together during assembly of frankenbox like this

Unfortunately it would appear that as I want to use the splines they can't be machined after welding so would not run true.

Plan B is to drill the MX5 shaft under the bearing and reduce the male spline to fit and roll pin - not very happy with that as it means the shaft will have to be taken down to about 15mm with a hard shoulder. The VW shaft would get the same treatment except it would need to be sleeved then the female spline roll pinned to it.

The cogs on the end of the MX5 bit looked like they were pressed on - but they certainly were not coming off with my 6T press so I chopped them off with the angle grinder (only about 10mm of shaft in the centre) so I could get access to the bearing which pressed off easily. Now frustrated by not having a lathe as I could do all this myself!

Like this (chopping the cogs off)

and this VW and MX5 female spline bit

like this

So that they could handily slide together during assembly of frankenbox like this

Unfortunately it would appear that as I want to use the splines they can't be machined after welding so would not run true.

Plan B is to drill the MX5 shaft under the bearing and reduce the male spline to fit and roll pin - not very happy with that as it means the shaft will have to be taken down to about 15mm with a hard shoulder. The VW shaft would get the same treatment except it would need to be sleeved then the female spline roll pinned to it.

The cogs on the end of the MX5 bit looked like they were pressed on - but they certainly were not coming off with my 6T press so I chopped them off with the angle grinder (only about 10mm of shaft in the centre) so I could get access to the bearing which pressed off easily. Now frustrated by not having a lathe as I could do all this myself!

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

Question, now I have chopped the cogs off and pressed off the bearing I have this

Diameter of the bearing mount part on the left is 30mm, What size should I have this drilled out to to fit and pin the splined shaft? 15mm as it is half the diameter or 21mm as that is half the surface area or something else..

Diameter of the bearing mount part on the left is 30mm, What size should I have this drilled out to to fit and pin the splined shaft? 15mm as it is half the diameter or 21mm as that is half the surface area or something else..

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

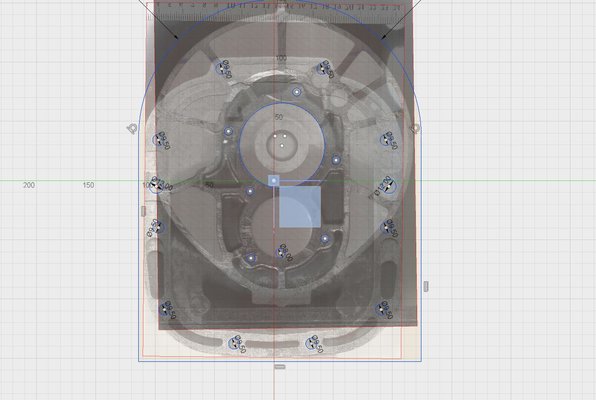

Well the good news is that my laser cut template fits like a.. well, like a laser cut template. Seriously though, the two 12mm holes fit over the two 11.99mm dowels - the positions of which were determined from the scan. These determine the centre of the bearing that holds the engine output shaft so not much tolerance allowed.

The bad news is that it took a loooong time to get the template and now I am still waiting on a price for the 2 real Ali plates.

The other bad news is that my local machine shop started mutterings about all sorts of expensive and time consuming things to connect the shafts as they are case hardened, so now I'm talking with someone oop north a bit more co-operative and motor sport orientated who might be able to weld the parts which would be my preferred route.

Unfortunately progress on pretty much everything else is stuck behind getting the engine mounted so I am getting garage withdrawal.

The bad news is that it took a loooong time to get the template and now I am still waiting on a price for the 2 real Ali plates.

The other bad news is that my local machine shop started mutterings about all sorts of expensive and time consuming things to connect the shafts as they are case hardened, so now I'm talking with someone oop north a bit more co-operative and motor sport orientated who might be able to weld the parts which would be my preferred route.

Unfortunately progress on pretty much everything else is stuck behind getting the engine mounted so I am getting garage withdrawal.

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

Change of direction on the shaft so now I just need 2 bits connecting together and I can mod the VW end to make it work.

Spoken to two separate recommended motorsport engineering shops, one said "sure, do it all the time no problem", the other said "nope, fail, disaster, need a new shaft making, which kidney would you like to sell" - however shop 1 has not been heard of since...

Sooo.. at the prompting of @dannyp on here I am investigating throwing away all my work so far and starting again and making a Franken clutch.

The VW clutch plate is 200mm and the 1.8L MX5 engine clutch is 215mm - consequently the MX5 flywheel and ring gear won't fit in the VW bell housing. However, I have discovered it is a known mod to put the 200mm clutch off a 1.6L on the 1.8L engine as a poor man's lightened flywheel, so if that would fit in the bell housing, a VW plate looks like a standard item, and if I can get the throw out bearing to work...

Spoken to two separate recommended motorsport engineering shops, one said "sure, do it all the time no problem", the other said "nope, fail, disaster, need a new shaft making, which kidney would you like to sell" - however shop 1 has not been heard of since...

Sooo.. at the prompting of @dannyp on here I am investigating throwing away all my work so far and starting again and making a Franken clutch.

The VW clutch plate is 200mm and the 1.8L MX5 engine clutch is 215mm - consequently the MX5 flywheel and ring gear won't fit in the VW bell housing. However, I have discovered it is a known mod to put the 200mm clutch off a 1.6L on the 1.8L engine as a poor man's lightened flywheel, so if that would fit in the bell housing, a VW plate looks like a standard item, and if I can get the throw out bearing to work...

PhillipM

Member

- Messages

- 3,084

On the rotary I machined the VW flywheel to fit the RX-8 crank and did it that way, although with the Honda we've just machined the Honda flywheel and put a different centre spline in the plate to suit the box.

Sorry I didn't reply to the PM, lost a family member a couple of days ago so been a bit hectic here, I'll take a look at the shaft when I get chance.

Sorry I didn't reply to the PM, lost a family member a couple of days ago so been a bit hectic here, I'll take a look at the shaft when I get chance.

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

Thanks Phil. Sorry to hear of your loss.

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

Riiight. So after a snowed in day on the 'net and getting continued mixed feedback on the shaft joint do-ability and reliability when done, I have switched focus to keeping the VW bell housing and input shaft as per @dannyp 's suggestion.

I would like to re-use the MX5 starter, flywheel and basket, just switching out the clutch plate for a VW one. Or if that won't work changing the centre spline of a MX5 plate for a VW one (no idea how though!) as per @PhillipM .

On the plus side the the spigot/pilot bearing fit is the same on both

On the minus side the MX5 ring gear is too big for the VW bell housing and it's the same on the 1.6L MX5 flywheel (duh... of course it is or the starter wouldn't work) so making an adapter plate whilst keeping the shaft length correct will be interesting..

so making an adapter plate whilst keeping the shaft length correct will be interesting..

Will need to modify the release bearing as my VW gearbox clutch has a centre pad rather than "fingers", it seems later Beetles changed the bearing but also added a guide tube for it. Back to the drawing board ...

I would like to re-use the MX5 starter, flywheel and basket, just switching out the clutch plate for a VW one. Or if that won't work changing the centre spline of a MX5 plate for a VW one (no idea how though!) as per @PhillipM .

On the plus side the the spigot/pilot bearing fit is the same on both

On the minus side the MX5 ring gear is too big for the VW bell housing and it's the same on the 1.6L MX5 flywheel (duh... of course it is or the starter wouldn't work)

so making an adapter plate whilst keeping the shaft length correct will be interesting..

so making an adapter plate whilst keeping the shaft length correct will be interesting..Will need to modify the release bearing as my VW gearbox clutch has a centre pad rather than "fingers", it seems later Beetles changed the bearing but also added a guide tube for it. Back to the drawing board ...

can you turn down the mx5 flywheel to take a vw starter ring and use the vw starter motor ?

it'd be really usefull to know excactly whitch vw box your useing, as for makeing n adaptor plate and keeping shaft lengths correct it has been known to put a nauhty spacer behind the flywheel

it'd be really usefull to know excactly whitch vw box your useing, as for makeing n adaptor plate and keeping shaft lengths correct it has been known to put a nauhty spacer behind the flywheel

CompoSimmonite

Member

- Messages

- 6,036

- Location

- Werrington, Staffordshire Moorlands.

Thinking differently.

Could you use a spacer between end of MX5 crank and flywheel to put it in the correct place so an unmodified VW gearbox shaft could be used ?

Having a spacer machined is going to be a lot easier and cheaper than a new shaft.

Could you use a spacer between end of MX5 crank and flywheel to put it in the correct place so an unmodified VW gearbox shaft could be used ?

Having a spacer machined is going to be a lot easier and cheaper than a new shaft.

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

@Ruffian

-VW starter is in it's bell housing

- Yes that is possible as VW Flywheels are held on by a few dowels and a big centre nut that doubles as a pilot bearing

but I don't have a VW clutch/flywheel as I sold it all with the engine (expensive things Aircooled 4 pots!)

@dannyp

- Not sure

- It's a 002 3 rib Bus gearbox (see Page 1 for pic!) unfortunately pre 1970 with old style release bearing.

@CompoSimmonite

-Yes the new plan (as above) is to use the VW shaft unmodified - due to issues with modifying shafts!

- Actually the problem is the other way!

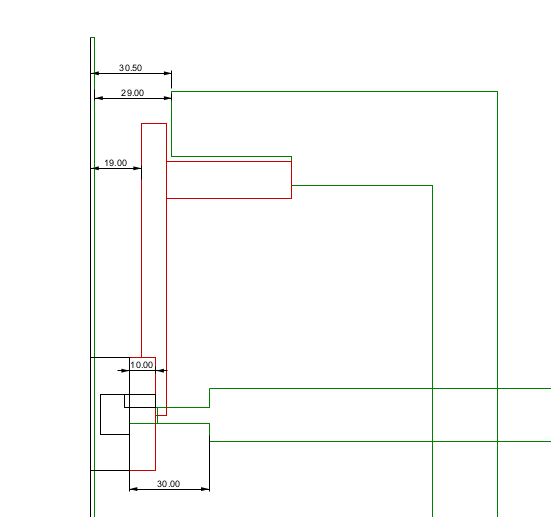

The MX5 shaft is back from it's bell housing face by 15mm, the VW shaft protrudes from its bell housing face by 16mm so I can move the VW bell housing back 31mm plus a couple of mm if needed.

The ring gear to engine face gap is 19mm, the ring gear is 9.5mm thick, I need an extra 2mm to make sure the clutch basket does not foul the VW bell housing - Total 30.5mm!

Rough sketch

- great except I need something for the VW bell housing to bolt on to so I might have to mill 10mm off the face of the bell housing to allow for an ali plate - or make it out of steel!

Talking of bell housings the VW one I have is for the old style throw out bearing that requires a central push plate on the basket like this

Unfortunately swapping to the later style that can work with the fingers of an MX5 basket is not easy as the bearing is different, but so is the mechanism and the arm diameter and, and... Upshot is I need a new later VW bell housing.

-VW starter is in it's bell housing

- Yes that is possible as VW Flywheels are held on by a few dowels and a big centre nut that doubles as a pilot bearing

but I don't have a VW clutch/flywheel as I sold it all with the engine (expensive things Aircooled 4 pots!)

@dannyp

- Not sure

- It's a 002 3 rib Bus gearbox (see Page 1 for pic!) unfortunately pre 1970 with old style release bearing.

@CompoSimmonite

-Yes the new plan (as above) is to use the VW shaft unmodified - due to issues with modifying shafts!

- Actually the problem is the other way!

The MX5 shaft is back from it's bell housing face by 15mm, the VW shaft protrudes from its bell housing face by 16mm so I can move the VW bell housing back 31mm plus a couple of mm if needed.

The ring gear to engine face gap is 19mm, the ring gear is 9.5mm thick, I need an extra 2mm to make sure the clutch basket does not foul the VW bell housing - Total 30.5mm!

Rough sketch

- great except I need something for the VW bell housing to bolt on to so I might have to mill 10mm off the face of the bell housing to allow for an ali plate - or make it out of steel!

Talking of bell housings the VW one I have is for the old style throw out bearing that requires a central push plate on the basket like this

Unfortunately swapping to the later style that can work with the fingers of an MX5 basket is not easy as the bearing is different, but so is the mechanism and the arm diameter and, and... Upshot is I need a new later VW bell housing.

CompoSimmonite

Member

- Messages

- 6,036

- Location

- Werrington, Staffordshire Moorlands.

Have you considered a 5 speed Skoda Estelle gearbox ?

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

Not looking to change gearbox or engine plans at the moment, but that's an interesting one.

Right now I am trying to find out if the T25 diesel bell housing is a larger diameter than the beetle one as that should bolt up to my 002 box and make like easier adapter plate wise.

Right now I am trying to find out if the T25 diesel bell housing is a larger diameter than the beetle one as that should bolt up to my 002 box and make like easier adapter plate wise.

There is a lot of info about t25 gearbox conversions on this forum.

http://forum.club8090.co.uk/viewtopic.php?f=37&t=144904

There is also someone called aiden on that forum who reconditions vw boxes, his details are in his posts. He will answer any questions about t25 boxes.

http://forum.club8090.co.uk/viewtopic.php?f=37&t=144904

There is also someone called aiden on that forum who reconditions vw boxes, his details are in his posts. He will answer any questions about t25 boxes.

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

Great thanks. For some reason "club8090" didn't immediately associate with the T25!

Spent several hours of searching to draw a blank on actual dimensions... I'll drop Aiden a line

Spent several hours of searching to draw a blank on actual dimensions... I'll drop Aiden a line

Last edited:

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

Wightsparks

Member

- Messages

- 1,533

- Location

- Wight

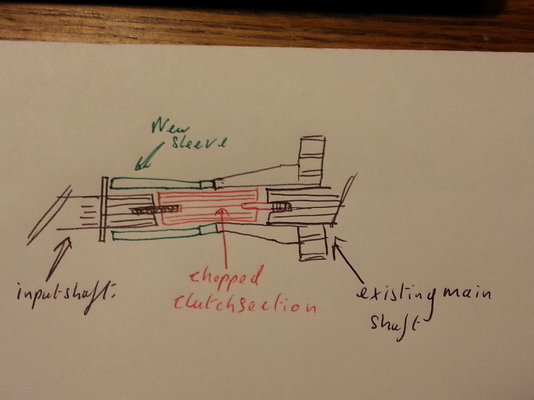

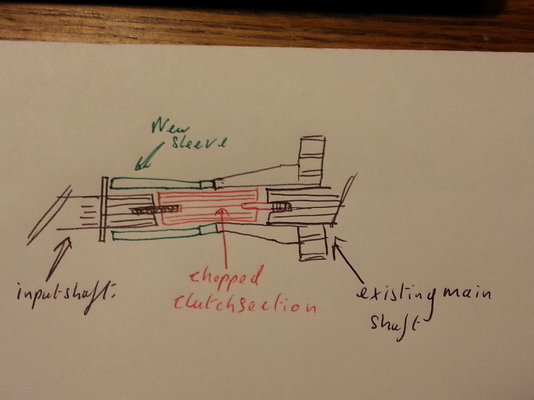

Had a shaft brainwave and finally .. a Plan! to use the MX5 part case and plates that I have designed

to use the MX5 part case and plates that I have designed

I can extend the shaft by using a splined sleeve off another gearbox and a chunk of clutch spline cut off another shaft. Actually I will buy a 298mm shaft and chop up the one I have. All VW parts and a splined sleeve is how the input shaft joins the main shaft as standard.

Like this (back of an envelope design)

This handily locates the smooth section of VW shaft at the intermediate MX5 bearing and seal so I will have a close fitting bush made up (I must get a lathe!) so that I can mount the MX5 bearing on it and the standard oil seal - duplicating the MX5 shaft at that point, probably with a bit of Loctite 638 to hold it in place.

Use a 215mm VW clutch plate on the shaft

Use all standard MX5 clutch etc.

... I think...

... I think...

to use the MX5 part case and plates that I have designed

to use the MX5 part case and plates that I have designedI can extend the shaft by using a splined sleeve off another gearbox and a chunk of clutch spline cut off another shaft. Actually I will buy a 298mm shaft and chop up the one I have. All VW parts and a splined sleeve is how the input shaft joins the main shaft as standard.

Like this (back of an envelope design)

This handily locates the smooth section of VW shaft at the intermediate MX5 bearing and seal so I will have a close fitting bush made up (I must get a lathe!) so that I can mount the MX5 bearing on it and the standard oil seal - duplicating the MX5 shaft at that point, probably with a bit of Loctite 638 to hold it in place.

Use a 215mm VW clutch plate on the shaft

Use all standard MX5 clutch etc.

... I think...

... I think...

Even with wood templates I would then have to transfer them to CAD as I don't have facilities to make them with the accuracy required. Hopefully this did the job!

Even with wood templates I would then have to transfer them to CAD as I don't have facilities to make them with the accuracy required. Hopefully this did the job!