You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Milling machine sled ideas wanted.

- Thread starter JMS1972

- Start date

James1979

Member

- Messages

- 8,434

- Location

- Orkney

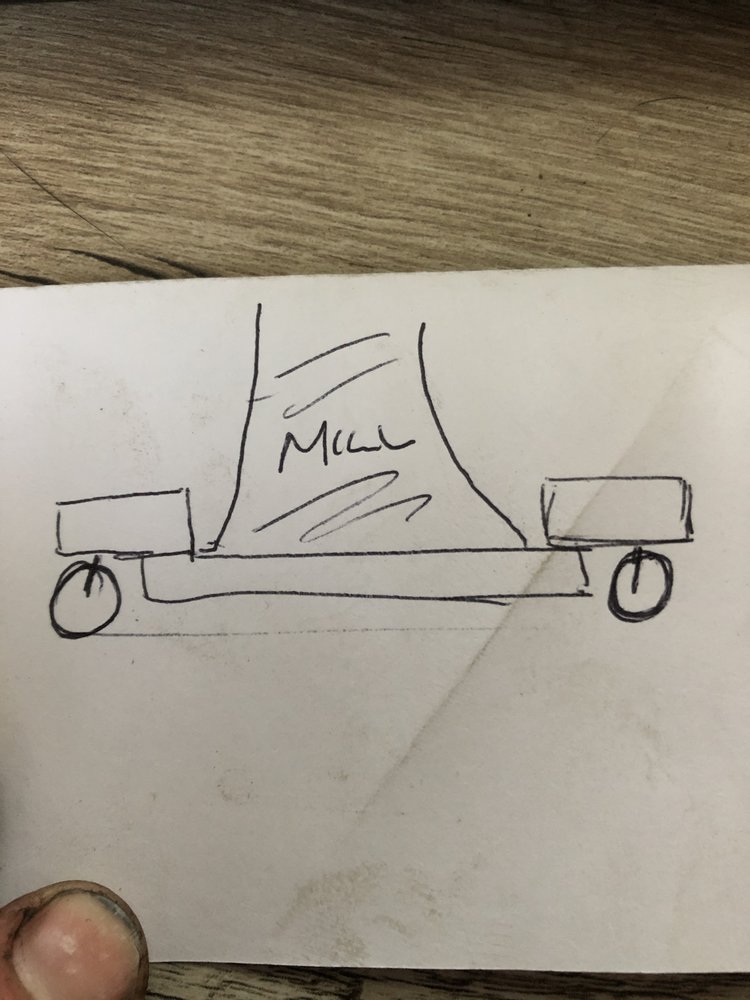

A low wide c of g is needed. I did this with my steel rack so I can move it about. This is the side view but you get the idea?

can take more pics if you want.

mine was 80x50x3 box as that’s what I had.

or build a frame with fork pockets on and buy a pump truck. Mine is one of the most used bits of kit in the workshop even though I can nick my neighbours load all when I need to.

can take more pics if you want.

mine was 80x50x3 box as that’s what I had.

or build a frame with fork pockets on and buy a pump truck. Mine is one of the most used bits of kit in the workshop even though I can nick my neighbours load all when I need to.

tflnemesis

Member

- Messages

- 650

Would some sort of jacking mechanism to lower frame to floor once moved be useful? Less likely to move when in use?

I have no idea if this is any help but it seems like a good idea to me as you are still in design stage.

Following with interest.

I have no idea if this is any help but it seems like a good idea to me as you are still in design stage.

Following with interest.

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

That's sort of what I was thinking if you have a pic that would be helpful.A low wide c of g is needed. I did this with my steel rack so I can move it about. This is the side view but you get the idea?

can take more pics if you want.

mine was 80x50x3 box as that’s what I had.

View attachment 294392

or build a frame with fork pockets on and buy a pump truck. Mine is one of the most used bits of kit in the workshop even though I can nick my neighbours load all when I need to.

I'm struggling for space - it's a single car garage so pump truck is a non starter.

Thanks

Hood

I am obsessed.

- Messages

- 17,295

- Location

- Carnoustie, Scotland

If possible I would have a frame with castors sitting slightly above the mill. I would have bolts through the holes in the base and welded to large washers underneath or better still a complete plate the size of the base. When I wanted to move I would tighten nuts thus lifting the mill to the frame and then once in place slacken to lower.

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

The machine has four holes for levelling feet so I could use big bolts in those. I need to figure how to float the mill in mid air whilst fitting the cradle so they could work double duty....Would some sort of jacking mechanism to lower frame to floor once moved be useful? Less likely to move when in use?

I have no idea if this is any help but it seems like a good idea to me as you are still in design stage.

Following with interest.

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

The machine has four holes for levelling feet so I could use big bolts in those. I need to figure how to float the mill in mid air whilst fitting the cradle so they could work double dutyWould some sort of jacking mechanism to lower frame to floor once moved be useful? Less likely to move when in use?

I have no idea if this is any help but it seems like a good idea to me as you are still in design stage.

Following with interest.

That's a good idea. Probably need fine pitch bolts as is a heavy beast.If possible I would have a frame with castors sitting slightly above the mill. I would have bolts through the holes in the base and welded to large washers underneath or better still a complete plate the size of the base. When I wanted to move I would tighten nuts thus lifting the mill to the frame and then once in place slacken to lower.

James1979

Member

- Messages

- 8,434

- Location

- Orkney

From the link it weighs 0.25 tons so that’s not a lot, especially in the machine tool world. Rigidity is more important than heavy duty I’d think but if you are going to lift it on jacking bolts then that isn’t such an issue.

I will take a few pics in a minute - heading back out there for a bit.

I will take a few pics in a minute - heading back out there for a bit.

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

I already have some home made Strongway type skates but they are a pain to use as it's slow to change their direction.im posting this for others

you want something more heavy duty so id say screwdown machine lifting system

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

That looks awesome thanks.

James1979

Member

- Messages

- 8,434

- Location

- Orkney

Thats exactly what I was getting at

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

Thanks I've got plenty of ideasIt’s a tilting roller table for loading the plasma from the steel rack to get sheets from vertical to horizontal. It needed to be stable as it has to handle 12mm sheets

knocked it up in about half hour and never got round to painting it.

View attachment 294472

View attachment 294473

Slightly off topic but do you have the 4 collets for it?I have a medium sized milling machine I'd like to be easy to move. It's one of These

4 heavy duty castors are available and was thinking of some sort of cradle with a perimeter frame for the castors.

Any ideas?

Thanks

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

Err nope it's an MT3 taper I think. I've got a milling chuck and that's about it.Slightly off topic but do you have the 4 collets for it?

I'm not sure I'm going to keep it, if I have room it might end up being CNC converted at some point.

Ah I thought they were all a proprietary taper. I only have a milling head for mine. Strangely I was going to Add some CNC motors but Tinbasher Dan was interested before Covid. Not sure if he is still interested but I still have all options openErr nope it's an MT3 taper I think. I've got a milling chuck and that's about it.

I'm not sure I'm going to keep it, if I have room it might end up being CNC converted at some point.