You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

feed liner

- Thread starter Derek c

- Start date

cumbriasteve

Moderator

- Messages

- 9,645

- Location

- Cumbria UK

Welcome to the forum, one of the most popular methods for replacing liners is to use the steel curtain wire and just cut it to the length of the old liner.

Thank you .so are all liners the same ie universal apart from length ?Welcome to the forum, one of the most popular methods for replacing liners is to use the steel curtain wire and just cut it to the length of the old liner.

cumbriasteve

Moderator

- Messages

- 9,645

- Location

- Cumbria UK

I am no expert on mig's but as far as I know the basic machines are, I have used curtain wire on two of mine and also done friends machines for them.

mike 109444

Member

- Messages

- 4,671

There are a few sizes AND lengths see link http://www.weldequip.com/eurotorch-liners.htm

Ebay will also have them listed.

Ebay will also have them listed.

I pulled the old nylon black liner out tonight and its diameter is 4 mm with a hole big enough to take .8 and .6 wire.

I have put a length of curtain plastic coated wire in as a replacement. Thè dimensions were the same.the wire is now in and the feed is running perfectly.

All i need now is a regulator and a kit to change over to 4mm gas feed. Then i can get the 180 going.and do some welding.

I have put a length of curtain plastic coated wire in as a replacement. Thè dimensions were the same.the wire is now in and the feed is running perfectly.

All i need now is a regulator and a kit to change over to 4mm gas feed. Then i can get the 180 going.and do some welding.

After getting the machine set up with gas.i switched it on . The power light was flickering and then went out then i switched it back on again and power light stayed on ..so pulled the trigger to weld gas was coming through.but the wire feed roller stopped spinning completely .could the problem be the curtain wire liner i fitted might be causing a short circuit .? Im baffled because yesterday the wire feed was good. Any advice would be gratefully received

mike 109444

Member

- Messages

- 4,671

The liner should not be the cause. Does the machine have a Euro type torch (one that can be disconnected from the machine ) see image at bottom of this page http://www.weldequip.com/mig-type15-torch.htm. If it does then you can cut weld wire just before the feed rollers. Keep hold of the end of wire to stop it unspooling from the reel and secure it to spool. Now remove torch and set aside. With machine turned on short the two small holes on the torch SOCKET using a paper clip or length of wire. This should make the machine run the feed motor. If it runs ok then there is an issue with your torch. If it still does not run the feed roller then the fault is internal to the machine (maybe the relay n pcb) All this only applies if t is a Euro torch.

If not a Euro torch then the "fixed" type torch fitted mry have an issue with the trigger / wiring inside torch. You would need a meter to check operation. If the trigger is feeding a signal into the machine then issue could be the pcb (relay on it). post pics of pcb to allow further guidance.

If not a Euro torch then the "fixed" type torch fitted mry have an issue with the trigger / wiring inside torch. You would need a meter to check operation. If the trigger is feeding a signal into the machine then issue could be the pcb (relay on it). post pics of pcb to allow further guidance.

Thanks i will investigate over the weekend.The liner should not be the cause. Does the machine have a Euro type torch (one that can be disconnected from the machine ) see image at bottom of this page http://www.weldequip.com/mig-type15-torch.htm. If it does then you can cut weld wire just before the feed rollers. Keep hold of the end of wire to stop it unspooling from the reel and secure it to spool. Now remove torch and set aside. With machine turned on short the two small holes on the torch SOCKET using a paper clip or length of wire. This should make the machine run the feed motor. If it runs ok then there is an issue with your torch. If it still does not run the feed roller then the fault is internal to the machine (maybe the relay n pcb) All this only applies if t is a Euro torch.

If not a Euro torch then the "fixed" type torch fitted mry have an issue with the trigger / wiring inside torch. You would need a meter to check operation. If the trigger is feeding a signal into the machine then issue could be the pcb (relay on it). post pics of pcb to allow further guidance.

mike 109444

Member

- Messages

- 4,671

Is it possible that you have turned the "spot weld" knob on ? It should be the bottom control knob.

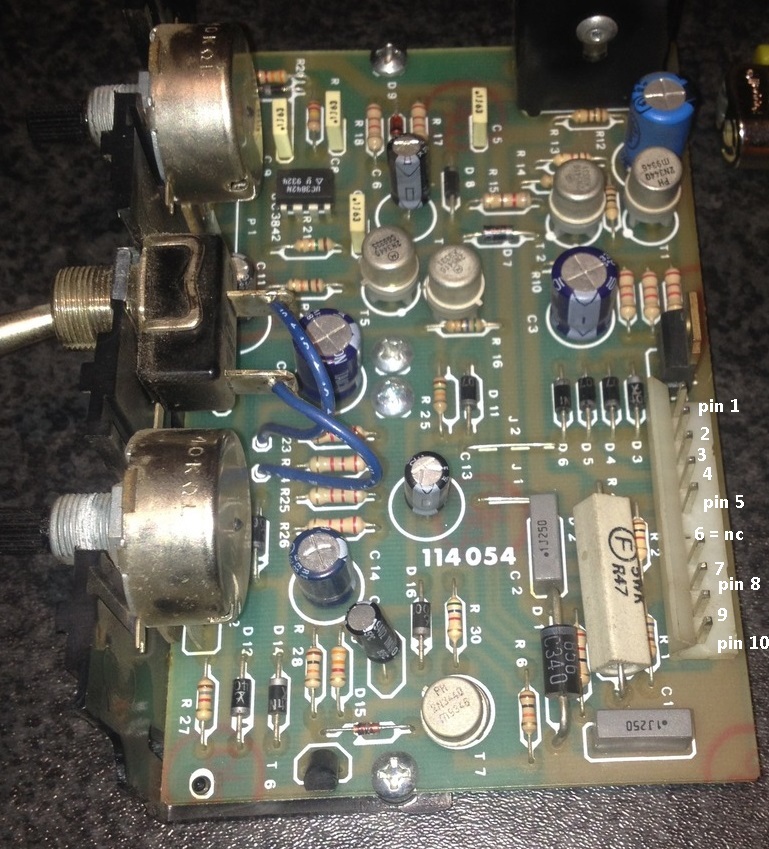

If not then looking at the images you have posted the board look very much like the 185/195 see pic. Note this has a 10 pin connector plug though. Yours I belive has an 8 pin (one pin not used so 7 wires).

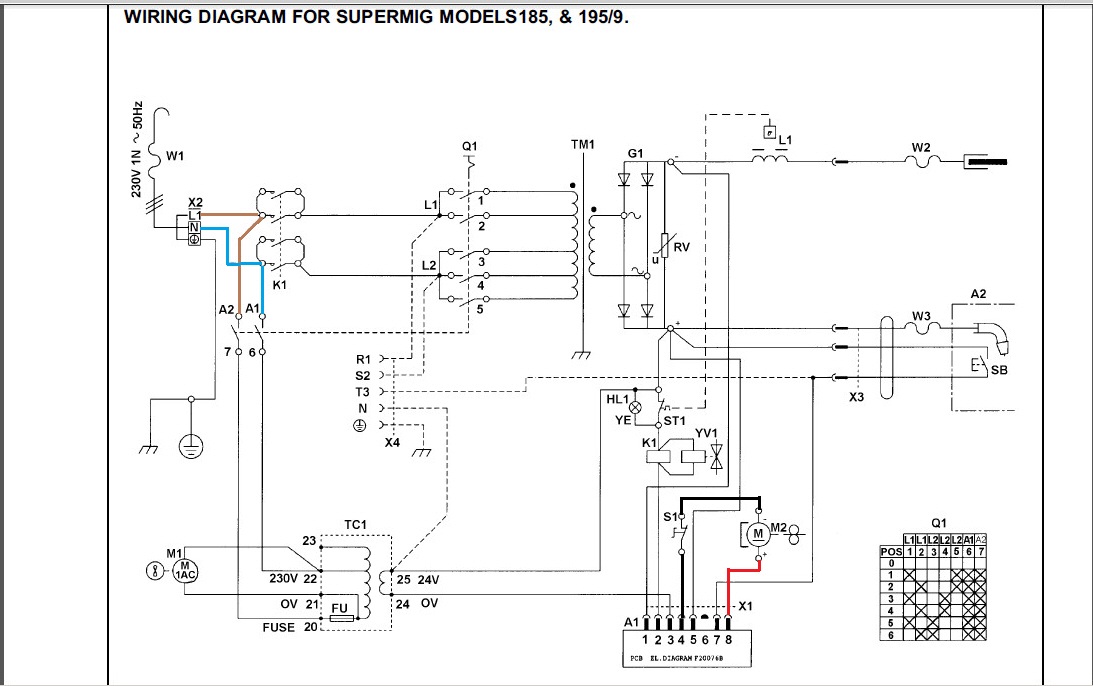

If you look at the diagram you will see that the mains power comes in (top left) , through the ON/OFF switch "A1 A2" Then goes to a step down transformer. This has a fuse in/on/by (FU) it that will kill the power out of that transformer (it's the transformer to the left of your gas valve in your pic) Note also if the fuse has blown then the fan (M1 bottom left on diagram) will not run, is your fan running ??

If not then looking at the images you have posted the board look very much like the 185/195 see pic. Note this has a 10 pin connector plug though. Yours I belive has an 8 pin (one pin not used so 7 wires).

If you look at the diagram you will see that the mains power comes in (top left) , through the ON/OFF switch "A1 A2" Then goes to a step down transformer. This has a fuse in/on/by (FU) it that will kill the power out of that transformer (it's the transformer to the left of your gas valve in your pic) Note also if the fuse has blown then the fan (M1 bottom left on diagram) will not run, is your fan running ??

Hi thanks for your help here.

The fuse is ok and the fan is running.

The spot timer has a toggle switch .and it is set to continuous welding not timed.

I recently fitted a liner made from a curtain wire could it be this causing the problem.

The fuse is ok and the fan is running.

The spot timer has a toggle switch .and it is set to continuous welding not timed.

I recently fitted a liner made from a curtain wire could it be this causing the problem.

mike 109444

Member

- Messages

- 4,671

Can't see changing the liner (for what ever type) would cause this issue. Only thing that might have got disturbed when you changed the liner would have been the connector shown in your pic of the feeder. I think that is the feed back from the torch button (goes to pin 7 of the plug on pcb) Should be possible to meter (set on ohms) between pin 7 and 5 while pressing the trigger should show a complete circuit each time it's pressed.

mike 109444

Member

- Messages

- 4,671

Items on diagram should be from top left:

W1 mains supply cable

X2 connector block

K1 the switching contacts of the contactor (this is operated by K1 coil, else where on diagram)

L1 & L2 the primary side (mains in) part of weld transformer

Q1 ?? maybe the OFF position of the power selector switch

TM1 the very big transformer, produces the lower AC voltage out for welding (after rectifying by G1

G1 takes the lower AC voltage from TM1 and rectifies it in to DC

RV soakes up any spikes on the output of the DC voltage.

L1 the thing that looks like a transformer but only has one wire in and one out (to the work ground lead) It helps with the weld arc stability

W2 the work clamp lead

A2 A1 the Mains ON/OFF switch

R1 S2 T3 N and X4 these I think are the connections on the contactor K1 (X4 being a connector block)

HL1 YE and ST1 are the over temperature switch (the metal disc about 1 inch in dia) mounted to the transformer windings plus the over temp lamp

K1 is the coil part of the contactor that pulls in the switching part of K1

YV1 is the gas valve coil

W3 welding torch lead

SB Torch trigger

M1 fan motor

TC1 small transformer that supplies low AC voltage to the pcb

S1 not sure what this is. It maybe part of the thermal cutout switch ST1 to stop the feed motor if welder goes over temp ??

M2 this is the wire feed motor

Q1 is the switching positions and what combinations they Make and Break

X1 is the header plug that plugs int the pcb

A1 is the pcb (no circuit diagram available for pcb

W1 mains supply cable

X2 connector block

K1 the switching contacts of the contactor (this is operated by K1 coil, else where on diagram)

L1 & L2 the primary side (mains in) part of weld transformer

Q1 ?? maybe the OFF position of the power selector switch

TM1 the very big transformer, produces the lower AC voltage out for welding (after rectifying by G1

G1 takes the lower AC voltage from TM1 and rectifies it in to DC

RV soakes up any spikes on the output of the DC voltage.

L1 the thing that looks like a transformer but only has one wire in and one out (to the work ground lead) It helps with the weld arc stability

W2 the work clamp lead

A2 A1 the Mains ON/OFF switch

R1 S2 T3 N and X4 these I think are the connections on the contactor K1 (X4 being a connector block)

HL1 YE and ST1 are the over temperature switch (the metal disc about 1 inch in dia) mounted to the transformer windings plus the over temp lamp

K1 is the coil part of the contactor that pulls in the switching part of K1

YV1 is the gas valve coil

W3 welding torch lead

SB Torch trigger

M1 fan motor

TC1 small transformer that supplies low AC voltage to the pcb

S1 not sure what this is. It maybe part of the thermal cutout switch ST1 to stop the feed motor if welder goes over temp ??

M2 this is the wire feed motor

Q1 is the switching positions and what combinations they Make and Break

X1 is the header plug that plugs int the pcb

A1 is the pcb (no circuit diagram available for pcb

mike 109444

Member

- Messages

- 4,671

Even though you say the contactor K1 is operating. That shows that coil K1 is being energized and also YV1, as they have the same feed BUT it could be that the contacts of K1 (the heavy current carrying ones in the contactor are burnt / pitted / in need of a clean (think points on a car if you are old enough  ). with some contactors it is possible to open them up and clean. but before you do try metering the contactors IN's and OUT's.

). with some contactors it is possible to open them up and clean. but before you do try metering the contactors IN's and OUT's.

To check contactor UNPLUG machine and then follow the mains lead into the machine. It should go to the ON/OFF switch and also to the contactor At X4, this is the IN's of the contactor. Now if you look at the other side of contactor there should be a set of THICK wires coming OUT. These are you OUT's. The other two thin wires are for the coil.

If you put a meter on the IN side with machine plugged in (TAKE CARE AS THIS IS MAINS VOLTAGE IN AND AROUND THE CONTACTOR ) There should be 240vAC if ok then put meter leads on the OUT's side and pull trigger. You should see 240vAC If not the contactor is sus/duff.

If there is 240 out then could be you have a fault on the pcb. Let me know the results of above test and if it looks like the pcb then there are a few (cheep) items on it that could be replaced to try and cure.

). with some contactors it is possible to open them up and clean. but before you do try metering the contactors IN's and OUT's.

). with some contactors it is possible to open them up and clean. but before you do try metering the contactors IN's and OUT's.To check contactor UNPLUG machine and then follow the mains lead into the machine. It should go to the ON/OFF switch and also to the contactor At X4, this is the IN's of the contactor. Now if you look at the other side of contactor there should be a set of THICK wires coming OUT. These are you OUT's. The other two thin wires are for the coil.

If you put a meter on the IN side with machine plugged in (TAKE CARE AS THIS IS MAINS VOLTAGE IN AND AROUND THE CONTACTOR ) There should be 240vAC if ok then put meter leads on the OUT's side and pull trigger. You should see 240vAC If not the contactor is sus/duff.

If there is 240 out then could be you have a fault on the pcb. Let me know the results of above test and if it looks like the pcb then there are a few (cheep) items on it that could be replaced to try and cure.

Hi Mike. Thanks for the help again.

I have checked the continuity of the trigger between pins 5 and 7 all ok there.

I have measured voltage coming out of the contactor suppliying the 240 volts this is ok too so the circuit is being fed.

It seems strange that both the wire feed and the welding voltage dont work ..does it look like the board then causing the fault ?

I have checked the continuity of the trigger between pins 5 and 7 all ok there.

I have measured voltage coming out of the contactor suppliying the 240 volts this is ok too so the circuit is being fed.

It seems strange that both the wire feed and the welding voltage dont work ..does it look like the board then causing the fault ?

mike 109444

Member

- Messages

- 4,671

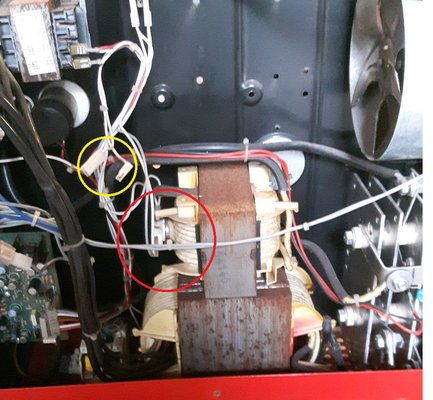

Looking back through the post I see you say that the "power light" is ON but if you are referring to the amber light on the front then I think you will find that is an over temp light HL1 on the diagram! If that is the light (and obviously you are not running it to go over temp) then it could be the over temp sensor ST1 that has stuck open circuit. See pic below of item in red circle. To check, pull the two spade connectors that are going into it and make up a link cable to join them together and see if that allows machine to operate.

Note can you also trace where the two unconnected wires go to as in the yellow circle.

Note can you also trace where the two unconnected wires go to as in the yellow circle.