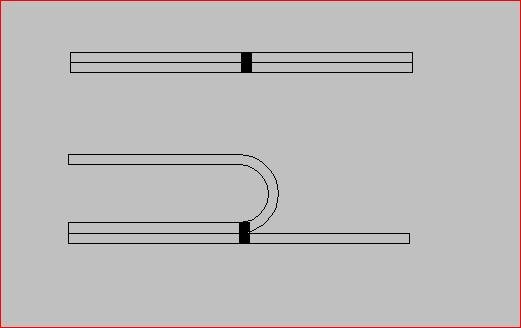

hi i am a bit unsure and need a bit of help, as title says is it possible to spot weld 3 pieces of metal together in 1 go, doing some repairs to car and have never used a spot welder before, can i weld floor lip, inner sill, outer sill together using a spot welder.

all metal is clean as its new the metal at a guess is 1mm each also need to know what setting to put spot wellder on?

the welder is a clarke csw 13t

the settings are

0.6+.06

0.8+0.8

1+1

1.2+1.2

1.5+1.5

2.2

now seeing as the total thickness is approx 3mm do i put it on 1.5+1.5 or do i put it on 1+1 as the metal is 1mm thick each?

any help would be great as i should be getting on with this tomorrow, will obviously be having some practice on some off cuts 1st to get the hang of it.

cheers for any help Richy

all metal is clean as its new the metal at a guess is 1mm each also need to know what setting to put spot wellder on?

the welder is a clarke csw 13t

the settings are

0.6+.06

0.8+0.8

1+1

1.2+1.2

1.5+1.5

2.2

now seeing as the total thickness is approx 3mm do i put it on 1.5+1.5 or do i put it on 1+1 as the metal is 1mm thick each?

any help would be great as i should be getting on with this tomorrow, will obviously be having some practice on some off cuts 1st to get the hang of it.

cheers for any help Richy

Last edited: