- Messages

- 6,153

- Location

- SW Scotland

Bid blind on and won a welder at an online auction for an old hire company. It didn't come with a good piccy and was listed as a MIG unit. I went to pick it up a few days later and it's a DC TIG unit and was wired for 415V

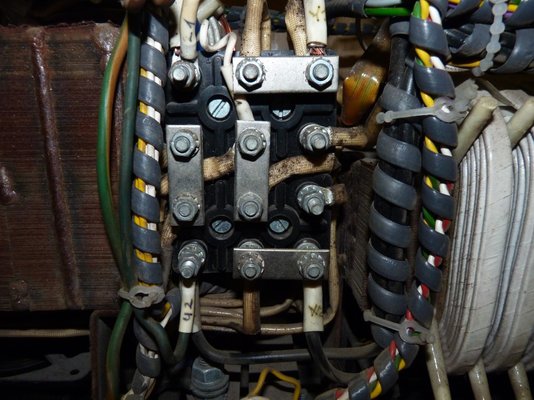

Got the thing home and by buggery it's heavy. Gotta weigh 40 Kg at least. Gutted to see the 415V plug on the end as I'm on normal domestic supply but the luck was with me and I saw on its back that it can do 110/240/415 by swapping some jumpers inside, yay! Needed a few other bits to get it back into service but it seems to work well now

Does anyone know anything about this unit? I've searched the forum and Google but can't find anything that seems relevant.

I'm very new to TIG; am I correct in thinking an arc welder has the same sort circuit inside as TIG? The reason I ask is I see people converting their arc units into TIG machines but I was wondering if you can dot he reverse and convert the TIG to do arc? Of course you'd need the rod clamp and some rods but I dunno if that's okay to do. There's a wee icon on a switch on the front of my machine that looks like a TIG torch in one setting and arc in the other, dunno if that's related though.

The gas hose that comes out of the torch dinse connector fouls against the earth lead. It's a tight squeeze to get the earth lead in and I'm concerned it'll damage the gas hose in the long run. Do you get 90 degree M->F parts for them? I'd like to sweep it downwards out of the way if possible.

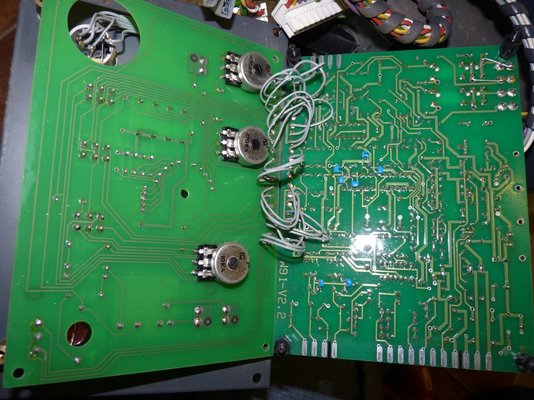

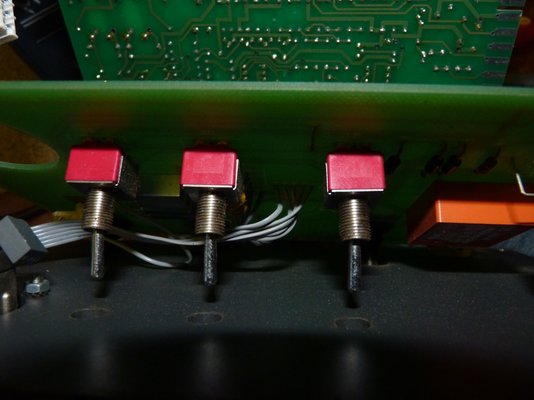

Last question - the three knobs at the top. I know the left hand one is ampage and the right hand one is gas time after the power goes off but what's the middle one for? If it's useful I'll replace the pot on the PCB as I don't think getting a new knob is a goer (it's got a weird setup and the end looks snapped off).

Got the thing home and by buggery it's heavy. Gotta weigh 40 Kg at least. Gutted to see the 415V plug on the end as I'm on normal domestic supply but the luck was with me and I saw on its back that it can do 110/240/415 by swapping some jumpers inside, yay! Needed a few other bits to get it back into service but it seems to work well now

Does anyone know anything about this unit? I've searched the forum and Google but can't find anything that seems relevant.

I'm very new to TIG; am I correct in thinking an arc welder has the same sort circuit inside as TIG? The reason I ask is I see people converting their arc units into TIG machines but I was wondering if you can dot he reverse and convert the TIG to do arc? Of course you'd need the rod clamp and some rods but I dunno if that's okay to do. There's a wee icon on a switch on the front of my machine that looks like a TIG torch in one setting and arc in the other, dunno if that's related though.

The gas hose that comes out of the torch dinse connector fouls against the earth lead. It's a tight squeeze to get the earth lead in and I'm concerned it'll damage the gas hose in the long run. Do you get 90 degree M->F parts for them? I'd like to sweep it downwards out of the way if possible.

Last question - the three knobs at the top. I know the left hand one is ampage and the right hand one is gas time after the power goes off but what's the middle one for? If it's useful I'll replace the pot on the PCB as I don't think getting a new knob is a goer (it's got a weird setup and the end looks snapped off).

Lol

Lol