You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7018 rods

- Thread starter Gingle

- Start date

Memmeddu

Member

- Messages

- 4,732

- Location

- Italia Sardegna

Well it depends upon what you are welding on, its function,its thickness and the joint importance itself.So ordered 7018 rods can I use these in this cold weather,also do I need to warm up metal plate with heat gun , before welding ,never used these rods 2.5 rods ,what am I looking out for for first try.

I've never had to preheat stuff for my own projects, but at work I do little bit every time I can

denlow60

Member

- Messages

- 163

can you show the code on the package, it contains most of the information.So ordered 7018 rods can I use these in this cold weather,also do I need to warm up metal plate with heat gun , before welding ,never used these rods 2.5 rods ,what am I looking out for for first try.

Gingle

We are all in the same boat

- Messages

- 373

- Location

- England uk Cambridge

E T

Member

- Messages

- 475

- Location

- Netherlands

For 2.5mm 7018 that's about right.Are we looking at 80 / 90 amps

Preheat of mild steel is not necessary unless its very thick.

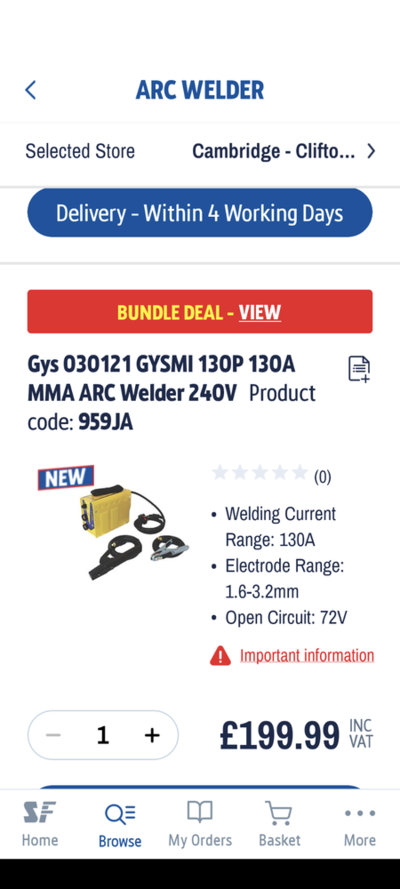

What welder are you using? OCV(open circuit voltage) can be a thing with 7018. 70V and higher is preferable.

E T

Member

- Messages

- 475

- Location

- Netherlands

That draper is 62V OCV. I think it will run 7018, but 7018 are harder to start than 6013. Higher OCV helps start and running them without sticking. The 62V is on the low side, but the hot start will help a bit. Most chinese inverters can handle 7018 relatively ok.

The Gys will run them, but I would go for the 160P. A bit more oomph is always better.

The Gys will run them, but I would go for the 160P. A bit more oomph is always better.

Arclikeharrypotter

Member

- Messages

- 1,257

- Location

- Northampton

Putting them on a radiator is going to do little to nothing. If the bucket or component is hardox might be worth grabbing a vac pac or a gentle pre heat7018 work fine in the cold, but in my experience, they really don't like being damp.

Which reminds me, I need to find my pack and stick them on a radiator as I have JCB bucket to weld :/

They only go on the radiator to dry them out, as they normally live in an unheated workshop.Putting them on a radiator is going to do little to nothing. If the bucket or component is hardox might be worth grabbing a vac pac or a gentle pre heat

E T

Member

- Messages

- 475

- Location

- Netherlands

You won't dry them out on a radiator. The flux acquires a chemical bond with the moisture and you need a lot more heat to break that bond.They only go on the radiator to dry them out, as they normally live in an unheated workshop.

That's why rod ovens for drying go up to 300 degrees celsius.

Memmeddu

Member

- Messages

- 4,732

- Location

- Italia Sardegna

And requires time too .You won't dry them out on a radiator. The flux acquires a chemical bond with the moisture and you need a lot more heat to break that bond.

That's why rod ovens for drying go up to 300 degrees celsius.

Roughly 4 hours at 365°C if I'm not mistaken

Going on my past experience, a couple days sat on the radiator makes them far better to use than when they've been sat in the workshop for months.You won't dry them out on a radiator. The flux acquires a chemical bond with the moisture and you need a lot more heat to break that bond.

That's why rod ovens for drying go up to 300 degrees celsius.

A rod oven would be better, but given how infrequently I actually use 7018 (or any rod for that matter), I can't really justify an oven.