JonnyAlpha

Member

- Messages

- 692

Hi;

I am making some repair panels and need some advice.

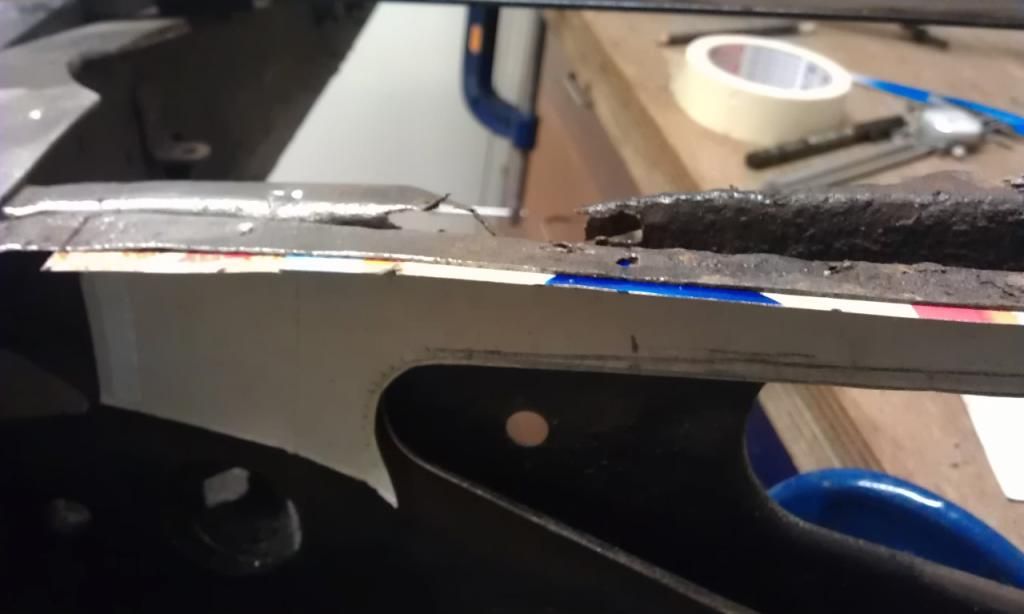

The first panel I am making is this one:

It is pretty straightforward and has some slight bends along its profile:

I have made a template for the panel by laying a piece of cardboard on it, marking it and cutting it out. I have used the template as a stencil and transferred the shape onto some 2mm sheet metal.

Here is the template and marked sheet metal:

Next step is to cut it out and bend it using the existing panel in place as a guide.

Question:

Based on the technique above once I cut the panel out and shape it using the existing panel once the existing panel is removed will my home made panel fit? Or is there anything else I need to do to take the bends into consideration?

Thanks

I am making some repair panels and need some advice.

The first panel I am making is this one:

It is pretty straightforward and has some slight bends along its profile:

I have made a template for the panel by laying a piece of cardboard on it, marking it and cutting it out. I have used the template as a stencil and transferred the shape onto some 2mm sheet metal.

Here is the template and marked sheet metal:

Next step is to cut it out and bend it using the existing panel in place as a guide.

Question:

Based on the technique above once I cut the panel out and shape it using the existing panel once the existing panel is removed will my home made panel fit? Or is there anything else I need to do to take the bends into consideration?

Thanks