- Messages

- 22,186

- Location

- Birmingham

Neat box for the controls  thought there would be a footswitch?

thought there would be a footswitch?

thought there would be a footswitch?

thought there would be a footswitch? thought there would be a footswitch?

thought there would be a footswitch?Can tell your a maintenance type person! We're the only ones that ever use sy. Did you remember to earth the braid!

Very nice, good to see one of my motors put to good use. And hope mine was the inspiration, if only to get on and build one

and you'll need that paint stirring speed for TIG

Neat box for the controlsthought there would be a footswitch?

Neat box for the controlsthought there would be a footswitch?

The footswitch idea has been rattling about in my head for a week or so.

I think i'll get another potentiometer for a footswitch then in the control box fit another switch to swap between the two potentiometers....maybe even a plug and socket to disconnect it all together when needed.

Does the footswitch need to be a speed controller? the ones I worked with were simply on/off types once the speed was set on the pot.

I see what you mean....possibly once i use it a bit and keep a record of the pot settings for mig or tig and the diameter of the bit being welded, on and off will be all it needs.

I have a spread sheet with Dia= IPM/RPM if you want me to email you it

Does the footswitch need to be a speed controller? the ones I worked with were simply on/off types once the speed was set on the pot.

Some of the ones i have looked at automatically stop start by sensing the welding current. Would that be easy enough to copy with some electronic wizzardry?

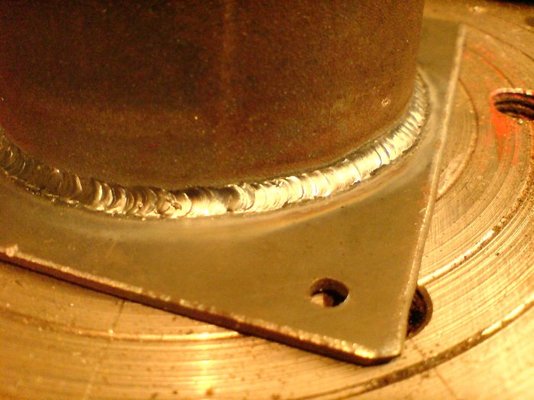

Machining a flat surface on the back of the table for the earth.

Bracket welded on to take the earth.

I was lucky enough to get one of these purpose made work returns from "Robotstar5"

It sure is a monster ...looks like it would be good for 500 amps or more.

Something like this pressing against the back of the face plate?

View attachment 31161

We use them on rotating welding fixtures and they last years with the occaisional lube with copaslip.

What are they called mate and where do they sell them??Something like this pressing against the back of the face plate?

View attachment 31161

We use them on rotating welding fixtures and they last years with the occaisional lube with copaslip.