You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

V8 trike build.

- Thread starter Morrisman

- Start date

Morrisman

Member

- Messages

- 8,097

- Location

- Staffordshire, England

Sudden burst of enthusiasm today, for some reason. The 10mm flat bar I ordered for the fork rockers arrived a few days back, so today I hit the workshop armed with coffee and a paper template. A hour of cutting steel with a 1mm cut off disc and I’ve got the basic shapes cut out.

There’s still a load of shaping required, and I've just discovered I’ve got no flap discs left.

Then I need to put 3/4” holes in.

Surprisingly it hardly wore the cut off disc down at all, maybe 15mm off the diameter, such is my gentle hand.

Then I decided to make a mandrel so I can mount my boring head in the drill press. It came with a #3 Morse, and my drill is #2 so cuts were made, metal was turned down in the lathe, and a spare #2 was welded to the stump.

There’s still a load of shaping required, and I've just discovered I’ve got no flap discs left.

Then I need to put 3/4” holes in.

Surprisingly it hardly wore the cut off disc down at all, maybe 15mm off the diameter, such is my gentle hand.

Then I decided to make a mandrel so I can mount my boring head in the drill press. It came with a #3 Morse, and my drill is #2 so cuts were made, metal was turned down in the lathe, and a spare #2 was welded to the stump.

Morrisman

Member

- Messages

- 8,097

- Location

- Staffordshire, England

So, I used the newly made grinding gadget to round out the rockers, then tack welded them in pairs. Plan was to bore all the holes out, but by experimenting on some scrap steel I found I could drill the 3/4 holes quite accurately with just a standard twist drill, so I did that.

The 1” holes weren’t so simple, I have no 1” drill, so I used a hole saw to open them to about 7/8“ then set up my boring bar gadget in the drill press.

I was very surprised how well it all went, until the end of the second hole…..when I found by boring tool was hitting the 1/2” HSS stock I had clamped down onto.

It knocked the tip off the boring tool but no great drama, reground, regrouped, and on we went.

It‘s only a clearance hole, but I wanted it somewhere near. With inside calipers and a micrometer I could get it to a thou or two, so I did.

The 1” holes weren’t so simple, I have no 1” drill, so I used a hole saw to open them to about 7/8“ then set up my boring bar gadget in the drill press.

I was very surprised how well it all went, until the end of the second hole…..when I found by boring tool was hitting the 1/2” HSS stock I had clamped down onto.

It knocked the tip off the boring tool but no great drama, reground, regrouped, and on we went.

It‘s only a clearance hole, but I wanted it somewhere near. With inside calipers and a micrometer I could get it to a thou or two, so I did.

zx9

Forum Supporter

- Messages

- 5,170

- Location

- South East London

Genius idea to use the drill press, I would have dismissed that as good in theory but it aint ever going to work in practice. Like they say necessity is the mother of inversion.So, I used the newly made grinding gadget to round out the rockers, then tack welded them in pairs. Plan was to bore all the holes out, but by experimenting on some scrap steel I found I could drill the 3/4 holes quite accurately with just a standard twist drill, so I did that.

View attachment 434045

View attachment 434043

The 1” holes weren’t so simple, I have no 1” drill, so I used a hole saw to open them to about 7/8“ then set up my boring bar gadget in the drill press.

I was very surprised how well it all went, until the end of the second hole…..when I found by boring tool was hitting the 1/2” HSS stock I had clamped down onto.

It knocked the tip off the boring tool but no great drama, reground, regrouped, and on we went.

It‘s only a clearance hole, but I wanted it somewhere near. With inside calipers and a micrometer I could get it to a thou or two, so I did.

View attachment 434044

Morrisman

Member

- Messages

- 8,097

- Location

- Staffordshire, England

I expected chattering or vibration at minimum, and the whole boring head simple dropping out of the taper at worst. So I was quite surprised it worked this well myself.Genius idea to use the drill press, I would have dismissed that as good in theory but it aint ever going to work in practice. Like they say necessity is the mother of inversion.

slim_boy_fat

Forum Supporter

- Messages

- 29,540

- Location

- Scottish Highlands

FTFYGenius idea to use the drill press, I would have dismissed that as good in theory but it aint ever going to work in practice. Like they say necessity is the mother ofinversioninvention.

zx9

Forum Supporter

- Messages

- 5,170

- Location

- South East London

Thank you John, it took me a while to work out what i had done wrong.FTFY

Morrisman

Member

- Messages

- 8,097

- Location

- Staffordshire, England

Despite all my careful pilot drilling and clamping solidly to the drill press, the 3/4” holes all appear to be a couple of degrees out of perpendicular to the face of the work piece.

I can‘t see how it could happen.

The idea was the holes would be used to align each piece for welding, using the 3/4” silver steel pivot pins, but now I’ve just squared the plates up to each other, and run some tig round the front of the main boss, and I’ll hack/file/ream the holes so the pivot pins go through. Maybe this should go in the Bodge thread.

I was surprised how well the tig cut into the steel, melted like butter, faster than I could add filler. Bit too much power methinks. This was on 120 amps, should have gone a bit lower, but it’s simply to keep things aligned when it’s all put together.

I can‘t see how it could happen.

The idea was the holes would be used to align each piece for welding, using the 3/4” silver steel pivot pins, but now I’ve just squared the plates up to each other, and run some tig round the front of the main boss, and I’ll hack/file/ream the holes so the pivot pins go through. Maybe this should go in the Bodge thread.

I was surprised how well the tig cut into the steel, melted like butter, faster than I could add filler. Bit too much power methinks. This was on 120 amps, should have gone a bit lower, but it’s simply to keep things aligned when it’s all put together.

What diameter filler rod do you use? I've welded 5mm t joints with about 160amps, I did try 1.6mm but gave up and ordered some 2.4mm, that made a world of difference.I was surprised how well the tig cut into the steel, melted like butter, faster than I could add filler. Bit too much power methinks. This was on 120 amps, should have gone a bit lower, but it’s simply to keep things aligned when it’s all put together.

Morrisman

Member

- Messages

- 8,097

- Location

- Staffordshire, England

1.6mm rods. I think the problem is I’m just not very competent yet. The torch seems big and cumbersome, and the hefty cable/hose adds to the problem.What diameter filler rod do you use? I've welded 5mm t joints with about 160amps, I did try 1.6mm but gave up and ordered some 2.4mm, that made a world of difference.

I really should practise more as it’s such a nice way to weld, none of the spatter and frenzy of stick or Mig.

addjunkie

Forum Supporter

- Messages

- 12,403

- Location

- Northumberland. Reet oot in the sticks

Try a small quality torch, with soft flex hose, its amazing how much easier it is. Was like night and day for me. Wp9.1.6mm rods. I think the problem is I’m just not very competent yet. The torch seems big and cumbersome, and the hefty cable/hose adds to the problem.

I really should practise more as it’s such a nice way to weld, none of the spatter and frenzy of stick or Mig.

Arc Tourist

Member

- Messages

- 4,884

- Location

- Wales

Put a straight rod in the chuck and check with an accurate square that the table is perfectly perpendicular to the rod. Also, the table may be flexing under the load when drilling large holes.Despite all my careful pilot drilling and clamping solidly to the drill press, the 3/4” holes all appear to be a couple of degrees out of perpendicular to the face of the work piece.

I can‘t see how it could happen.

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

After all, a drill press is not built to the accuracy standards of a milling machine.

Morrisman

Member

- Messages

- 8,097

- Location

- Staffordshire, England

It’s a fairly robust old thing, but I was clamped right on the edge of the table to get my G cramps on, so maybe it did flex.Put a straight rod in the chuck and check with an accurate square that the table is perfectly perpendicular to the rod. Also, the table may be flexing under the load when drilling large holes.

After all, a drill press is not built to the accuracy standards of a milling machine.

I shall break out my DTI and mount it in the chuck, swing an arc across the table to see if it’s really a square as I thought it was.

But as an old plater I once knew told me:

There’s no such thing as a mistake, only more welding.

Morrisman

Member

- Messages

- 8,097

- Location

- Staffordshire, England

I currently have a wp26 torch, good for 200amps. My tig unit is only 160. I nearly just hit the ‘buy’ button on a wp9 on the r-tech site, but decided to call up and ask. Good job, the only difference between the two is the size of the consumables on the end, body and cable are identical…….Try a small quality torch, with soft flex hose, it’s amazing how much easier it is. Was like night and day for me. Wp9.

They sell a ck9 torch, USA made, that the guy recommended, but it’s not cheap. I assume consumable will be on top of the price shown. The guy is putting together a package deal and emailing it. I shall await its arrival.

addjunkie

Forum Supporter

- Messages

- 12,403

- Location

- Northumberland. Reet oot in the sticks

Its a ck wo 9 I have, far better than the cheapies and far smaller, than a w26. If I were looking to buy one Id look at rapid welding, then youd get genuine ck consumables too. You will also need to buy the switch and correct plug too.

rapidwelding.com

rapidwelding.com

ill take some pics of mine next to a paraweld 26 for you

Choose from our Extensive Range of CK9 . Welding Machines, Equipment & Supplies from Rapid Welding

Buy CK9 , from Rapid Welding Supplies. See our Full Range of Welders & Welding Equipment on site & Buy On-line Now for great discounts!

ill take some pics of mine next to a paraweld 26 for you

Morrisman

Member

- Messages

- 8,097

- Location

- Staffordshire, England

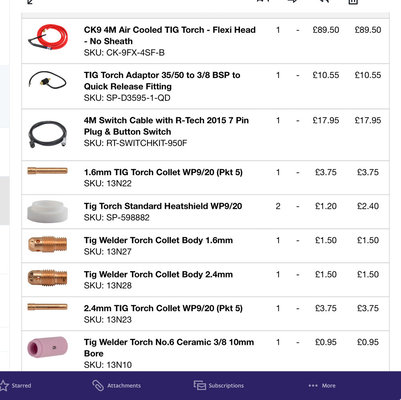

I’ve had the quote, with the torch, an adaptor to switch it, a box of the right sized consumables etc etc it come to £142. Which is better than I expected having priced up the plug and play model. I could even see about making a foot pedal switch, for an experiment. I’ve just hit the ‘buy’ button.Its a ck wo 9 I have, far better than the cheapies and far smaller, than a w26. If I were looking to buy one Id look at rapid welding, then youd get genuine ck consumables too. You will also need to buy the switch and correct plug too.

Choose from our Extensive Range of CK9 . Welding Machines, Equipment & Supplies from Rapid Welding

Buy CK9 , from Rapid Welding Supplies. See our Full Range of Welders & Welding Equipment on site & Buy On-line Now for great discounts!rapidwelding.com

ill take some pics of mine next to a paraweld 26 for you

Hopefully this will turn my £700 Tig welder investment into something more enjoyable to use.

addjunkie

Forum Supporter

- Messages

- 12,403

- Location

- Northumberland. Reet oot in the sticks

Buy a soft flexible sheath, to protect your new expensive torch! Guess I dont need to take pictures now eitherI’ve had the quote, with the torch, an adaptor to switch it, a box of the right sized consumables etc etc it come to £142. Which is better than I expected having priced up the plug and play model. I could even see about making a foot pedal switch, for an experiment. I’ve just hit the ‘buy’ button.

Hopefully this will turn my £700 Tig welder investment into something more enjoyable to use.

View attachment 434985

Did you miss this bit off your order

Snap on Torch Button Housing for Small Handle - Welding Supplies from Rapid Welding

Looking for...... RDZ0591, Snap on Torch Button Housing for Small Handle

this is the cover

Weldas Cable Cover 22mm 3mtr Lightbrown Leather - Welding Supplies from Rapid Welding

Looking for...... 44-3010Z, Weldas Cable Cover 22mm 3mtr Lightbrown Leather

Morrisman

Member

- Messages

- 8,097

- Location

- Staffordshire, England

The guy I spoke to said that I could cable tie the switch to wherever I wanted to on the torch. It gives me scope to find a comfortable position. The stock torch the welder came with has the button in a daft position, really awkward to reach. I can look into changes or updates later I reckon.Buy a soft flexible sheath, to protect your new expensive torch! Guess I dont need to take pictures now either

Did you miss this bit off your order

Snap on Torch Button Housing for Small Handle - Welding Supplies from Rapid Welding

Looking for...... RDZ0591, Snap on Torch Button Housing for Small Handlerapidwelding.com

this is the cover

Weldas Cable Cover 22mm 3mtr Lightbrown Leather - Welding Supplies from Rapid Welding

Looking for...... 44-3010Z, Weldas Cable Cover 22mm 3mtr Lightbrown Leatherrapidwelding.com

The cable cover, might look into that too if I think it’s needed. In the last two years I’ve probably done a total of 2 hours tig welding, so hopefully that will increase.

Morrisman

Member

- Messages

- 8,097

- Location

- Staffordshire, England

New torch arrived, I‘m gob smacked how small and light it is compared to the original unit.

I‘m toying with making a foot switch, rather than have the switch fastened to the torch. Not a foot pedal as such, just a simple on/off. That would make the hand set as nimble as possible and save a wire running up the hose.

I‘m toying with making a foot switch, rather than have the switch fastened to the torch. Not a foot pedal as such, just a simple on/off. That would make the hand set as nimble as possible and save a wire running up the hose.