You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wire feed failure

- Thread starter stanman

- Start date

"as the wire feed is powered by the welding current"

As Aesgarth suggested, the "auto" part of a Migatronic Automig refers to the fact that as you wind up the welding power, the wirefeed speed does increase.

However, this is just a bias to the control logic, there is still a power supply for the motor.

When you press the torch trigger, do you still get an arc at the torch tip? Does the gas valve still open?

If you slacken the pressure roller, can you pull the MIG wire through the torch lead, torch head, and the tip?

If you press the torch trigger with the pressure roller released, does the motor and drive roller rotate?

These motors usually run on 24v DC. You could disconnect the motor leads and test the motor itself with a 12v battery.

As Aesgarth suggested, the "auto" part of a Migatronic Automig refers to the fact that as you wind up the welding power, the wirefeed speed does increase.

However, this is just a bias to the control logic, there is still a power supply for the motor.

When you press the torch trigger, do you still get an arc at the torch tip? Does the gas valve still open?

If you slacken the pressure roller, can you pull the MIG wire through the torch lead, torch head, and the tip?

If you press the torch trigger with the pressure roller released, does the motor and drive roller rotate?

These motors usually run on 24v DC. You could disconnect the motor leads and test the motor itself with a 12v battery.

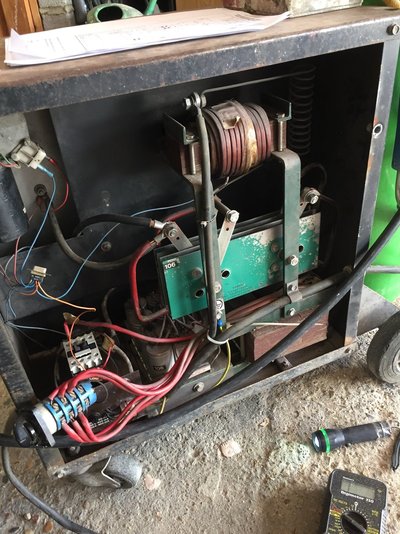

After much help and advice from Adrian, we have established my rectifier has burnt out and needs replacing! My question is, has anyone ever fitted a rectifier off eBay to a migatronic 180 automig? The one I have seen is 290 amps but appears to have only three points of attachment. Whereas my original has five points! Anyone got any ideas or suggestions ? Regards stanman

After much help and advice from Adrian, we have established my rectifier has burnt out and needs replacing! My question is, has anyone ever fitted a rectifier off eBay to a migatronic 180 automig? The one I have seen is 290 amps but appears to have only three points of attachment. Whereas my original has five points! Anyone got any ideas or suggestions ? Regards stanmanA full-wave rectifier can be built using only two diodes, but would need to be used with a transformer that has a centre-tapped secondary..

Your full-wave rectifier is for a transformer with a standard secondary, with just two wires out, no centre-tap. The rectifier will have four diodes, and is known as a "bridge rectifier". There will be two AC connections in ( marked ~ ~ ), and two DC connections out ( + and - ) . They are also available on eBay, for example:

https://www.ebay.co.uk/itm/290-AMP-SINGLE-PHASE-MIG-WELDER-BRIDGE-RECTIFIER/223607190069

Your full-wave rectifier is for a transformer with a standard secondary, with just two wires out, no centre-tap. The rectifier will have four diodes, and is known as a "bridge rectifier". There will be two AC connections in ( marked ~ ~ ), and two DC connections out ( + and - ) . They are also available on eBay, for example:

https://www.ebay.co.uk/itm/290-AMP-SINGLE-PHASE-MIG-WELDER-BRIDGE-RECTIFIER/223607190069

On that 290 Amp rectifier, the two AC inputs go to the heavy solid copper wires from your main transformer. The positive output will go to the MIG torch ( if using solid MIG wire and gas ), and the negative will go the the work return clamp ( "Earth " ), normally via the inductor ( choke ).

I think that your machine has a bank of capacitors. They are polarised, and will go across the positive and negative rectifier outputs, before the inductor. Hopefully the new part will come with documentation showing the two AC inputs and the pos and neg outputs. The four connections are the two inner tags, the centre tag, and the U-shaped cross-bar. All are drilled for bolts - about 6mm.

Note that the four "effective" diodes in that component are actually 8 small diodes in parallel, pressed into each of the four aluminium plates, and the plates are insulated from each other and from the mounting bolts, by shouldered nylon washers. The two bolts ( studs ) are therefore just for mounting. They can bolt to the flat metal strips that support the choke.

I think that your machine has a bank of capacitors. They are polarised, and will go across the positive and negative rectifier outputs, before the inductor. Hopefully the new part will come with documentation showing the two AC inputs and the pos and neg outputs. The four connections are the two inner tags, the centre tag, and the U-shaped cross-bar. All are drilled for bolts - about 6mm.

Note that the four "effective" diodes in that component are actually 8 small diodes in parallel, pressed into each of the four aluminium plates, and the plates are insulated from each other and from the mounting bolts, by shouldered nylon washers. The two bolts ( studs ) are therefore just for mounting. They can bolt to the flat metal strips that support the choke.

The connections on the 290 Amp eBay rectifier are almost identical to your original rectifier, as pictured in your post number 5. One difference is that the two outer plates on yours have tabs joined by a bolt, but the new one uses a U-shaped flat bar.

On the right-hand end there are two tabs ( flat metal straps with ~6mm bolt holes ). These are the two AC input connections, and will bolt to the thick solid copper wires coming up from the secondary of the main welding transformer. The eBay Seller has marked these with squiggly lines ( the symbol for AC : "~" ) in his picture.

Then on the left-hand end of the rectifier there is one tab that is in the exact middle of the stack of plates - that is the Positive output. It will connect to the MIG torch, and to the positive side of your capacitors.

The two outermost aluminium plates are joined by a flat metal bar, with one bolt hole. That is the Negative output, and it will connect to the choke, and the negative side of your capacitors.

As I suggested in my post number 9, and the Seller has confirmed, the two long mounting studs are fully insulated from the rectifier connections, and are to be used for physical mounting only. So they will be bolted into the flat metal bars that go up from the transformer frame to the choke frame. You may have to add a bracket if the horizontal spacing of the bars does not match the spacing of the rectifier mounting studs. None of the aluminium plates can touch the framework or the case of the machine.

It would perhaps be a good idea to confirm the polarity of the rectifier output before you connect the capacitor bank into the circuit. If that is reversed, the capacitors will explode...

Before you connect it, insulate one of the thick cables that leads to the capacitors, power up the welder, press the trigger, and use a meter to confirm that the positive rectifier output ( the tab in the centre of the stack of plates ) has about +20v DC on it. If that's OK, power off and wire in the capacitors.

On the right-hand end there are two tabs ( flat metal straps with ~6mm bolt holes ). These are the two AC input connections, and will bolt to the thick solid copper wires coming up from the secondary of the main welding transformer. The eBay Seller has marked these with squiggly lines ( the symbol for AC : "~" ) in his picture.

Then on the left-hand end of the rectifier there is one tab that is in the exact middle of the stack of plates - that is the Positive output. It will connect to the MIG torch, and to the positive side of your capacitors.

The two outermost aluminium plates are joined by a flat metal bar, with one bolt hole. That is the Negative output, and it will connect to the choke, and the negative side of your capacitors.

As I suggested in my post number 9, and the Seller has confirmed, the two long mounting studs are fully insulated from the rectifier connections, and are to be used for physical mounting only. So they will be bolted into the flat metal bars that go up from the transformer frame to the choke frame. You may have to add a bracket if the horizontal spacing of the bars does not match the spacing of the rectifier mounting studs. None of the aluminium plates can touch the framework or the case of the machine.

It would perhaps be a good idea to confirm the polarity of the rectifier output before you connect the capacitor bank into the circuit. If that is reversed, the capacitors will explode...

Before you connect it, insulate one of the thick cables that leads to the capacitors, power up the welder, press the trigger, and use a meter to confirm that the positive rectifier output ( the tab in the centre of the stack of plates ) has about +20v DC on it. If that's OK, power off and wire in the capacitors.

Last edited:

Sorry ! I'm sure that eBay one will be OK, I was just suggesting to double-check the output polarity.

These flat-aluminium-plate rectifiers are built with multiple press-fit small diodes, two or three or more taking the place of each of the four diodes that you need to make a full-wave bridge rectifier. These small diodes share the current, rather than using four single massive stud-mounted diodes. The press-fit diodes aren't easy to source, and replacements really should be matched to the originals, so that the total current is shared equally.

The rectifier would have to be dismantled, to find out how many of the small diodes have failed, and what type they are, then check if they are available. If you want to send the rectifier to me, I could do this for you...

These flat-aluminium-plate rectifiers are built with multiple press-fit small diodes, two or three or more taking the place of each of the four diodes that you need to make a full-wave bridge rectifier. These small diodes share the current, rather than using four single massive stud-mounted diodes. The press-fit diodes aren't easy to source, and replacements really should be matched to the originals, so that the total current is shared equally.

The rectifier would have to be dismantled, to find out how many of the small diodes have failed, and what type they are, then check if they are available. If you want to send the rectifier to me, I could do this for you...

Rig Pig

Member

- Messages

- 3,744

- Location

- Narrwich! U.K.

Sorry ! I'm sure that eBay one will be OK, I was just suggesting to double-check the output polarity.

These flat-aluminium-plate rectifiers are built with multiple press-fit small diodes, two or three or more taking the place of each of the four diodes that you need to make a full-wave bridge rectifier. These small diodes share the current, rather than using four single massive stud-mounted diodes. The press-fit diodes aren't easy to source, and replacements really should be matched to the originals, so that the total current is shared equally.

The rectifier would have to be dismantled, to find out how many of the small diodes have failed, and what type they are, then check if they are available. If you want to send the rectifier to me, I could do this for you...

Out of interest how do you match diodes?