Jacktegla

Member

- Messages

- 648

- Location

- Denbighshire

I've got a parweld xte171c and its been great for the past few years but I've noticed over the past couple of months this problem where I can get porosity in the welds sometimes but not others even when only minutes apart without changing settings.

Sometimes it won't happen and it will weld ok but others I cant get a weld without porosity ive attatched the settings ive used on these few test welds to show what happens. Any ideas? Thanks

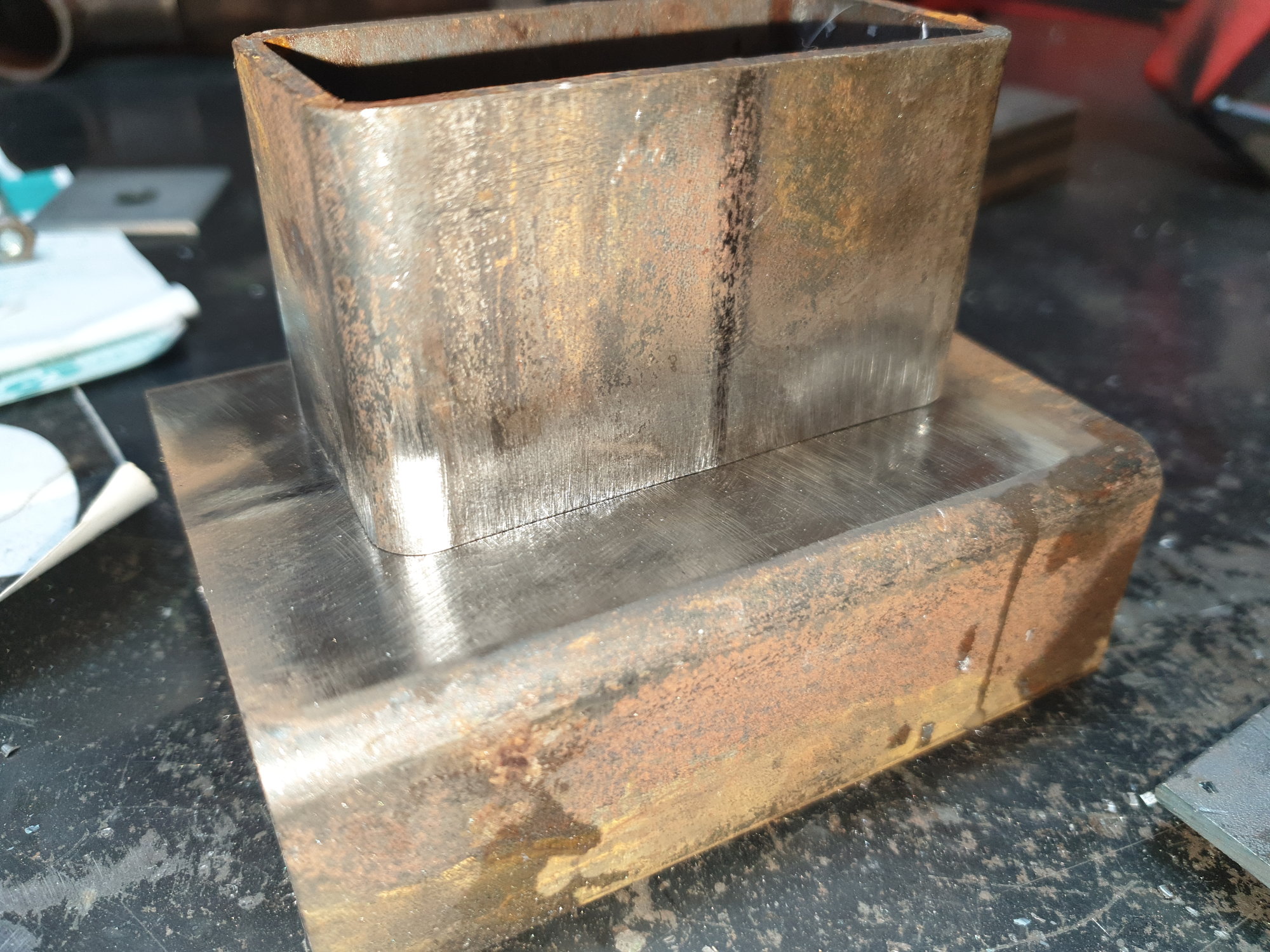

No porosity in these welds which i did first, then I did these.

No porosity in these welds which i did first, then I did these.

Sometimes it won't happen and it will weld ok but others I cant get a weld without porosity ive attatched the settings ive used on these few test welds to show what happens. Any ideas? Thanks