My Dad has had a Boxford Model A(UD) lathe that has been sitting in his basement for probably 20 years or so, gathering dust. I've occasionally pestered him to get it running so that he might get a bit of enjoyment out of it, but he's never quite got around to it. It's a 3 phase motor obviously, and while he does actually have a 3 phase supply in the house, extending the wiring to reach the lathe isn't necessarily an easy job.

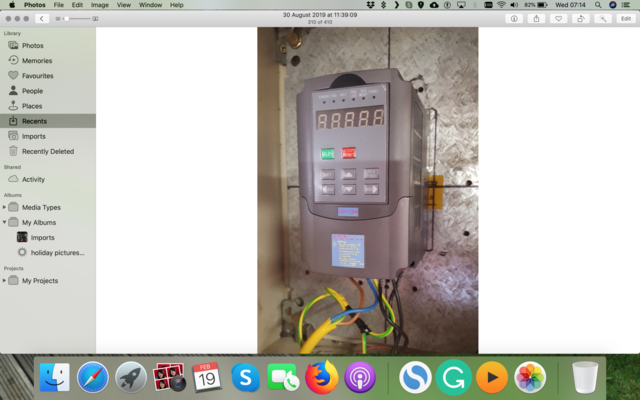

I recently learned about the existence of VFDs. This seems like a relatively straightforward way to get it operating on a single phase supply. I was wondering if anybody might have some advice on a suitable unit? It's probably not going to get masses of use so I'm not looking to spend a lot of money; I'm thinking cheap Chinese ebay job rather than bespoke hand crafted German, if you get my drift. Anyway, the motor plate reads:

Gryphon Brook Motors

3 phase 1420 RPM

50 Hz 400/400 Volts

0.75 HP Type PROT

1.38 F.L. amps Rating CONT

50C RISE

Any advice gratefully received!

I recently learned about the existence of VFDs. This seems like a relatively straightforward way to get it operating on a single phase supply. I was wondering if anybody might have some advice on a suitable unit? It's probably not going to get masses of use so I'm not looking to spend a lot of money; I'm thinking cheap Chinese ebay job rather than bespoke hand crafted German, if you get my drift. Anyway, the motor plate reads:

Gryphon Brook Motors

3 phase 1420 RPM

50 Hz 400/400 Volts

0.75 HP Type PROT

1.38 F.L. amps Rating CONT

50C RISE

Any advice gratefully received!