I'm writing this for the benefit of those that may be interested in this machine. I recently found myself in need of a new welder and came across the parweld machines. I quite liked the specs of the machine and had tig comparability which is something I always wanted to try my hand at. Anyway I could not find any info or reviews other than parwelds sales info. After a weeks pondering over it I bit the bullet and bought. And it arrived two days later to n.Ireland which isn't bad.

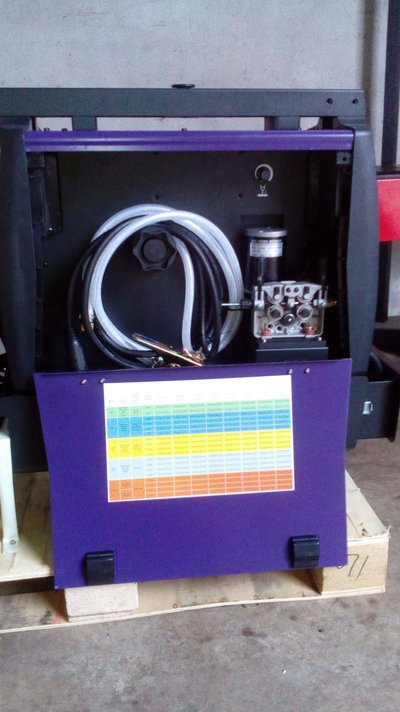

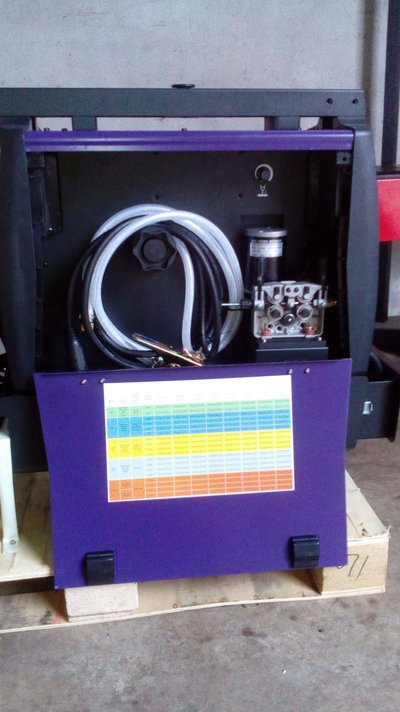

There is a drawer for consumables or what ever you want to put in it. Parweld neglected to mention this in their sales literature for some reason I think its a nice touch.

4 roller feed and is that burn back control?

No mention of it anywhere in manual.

Now the spindle for wire reel seams bit flimsy for 15kgs, may be something that may give trouble in future maybe not time will tell.

There also was 6 screws loose on the cover, maybe came loose in transit or never tightened at factory well never know but no major biggie

Quick note on the torch.

It comes with a parweld xp8 200a torch. I only had 0.8 wire at hand so went to local welding supply shop to get 0.8 tips as welder comes set up for 1.0mm. they had not seen these tips yet maybe a new design? So bought a roll of 1.0mm wire and came back and done a google/eBay search on the tips. Was shocked at the price of consumables for this torch. Only seam to be available genuine parweld at the moment.

Now I started the welder up for the first test weld on 2.5mm sheet. Set it in synergic mode and away I went. Now I would never have considered myself a good welder but I can stick things together with good penetration it just wouldn't have looked the part. But look at how neat and smooth the first weld it put out. No spatter in sight even tho its rusty sheet.

The oily scratched camera lens on my phone doesn't do it justice lol. Its better lookin real life.

Now it could have done with a bit more heat but you can trim the synergic settings.

Have done a quite a few more welds after this on the same sheet and 1mm sheet. Haven't had a chance to get trying good heavy stuff yet but so far I'm well impressed with it.

Only other point let's it down a bit is once you switch off synergic mode into normal mode the display where the amps were showen changes to display wire feed speed. You have to sort of guess the correlation between wfs/amps. Maybe with a bit of use I'd get the hang of it.

Next thing is to get trying out the tig. Just out of interest can you get a tig torch that plugs into euro connection so I can control the gas and current switch?

Now on to the price.

I don't know if I'm allowed names on here, if not then mods delete this part.

I ordered online from welding supplies direct and done a search for discount codes and found 10% discount code on there Facebook page (PROMO10)

The original price was 888plus so saved 106 quid with the code.

Hope this is helps anyone who couldn't find any info on this welder. I will update if I find any problems.

There is a drawer for consumables or what ever you want to put in it. Parweld neglected to mention this in their sales literature for some reason I think its a nice touch.

4 roller feed and is that burn back control?

No mention of it anywhere in manual.

Now the spindle for wire reel seams bit flimsy for 15kgs, may be something that may give trouble in future maybe not time will tell.

There also was 6 screws loose on the cover, maybe came loose in transit or never tightened at factory well never know but no major biggie

Quick note on the torch.

It comes with a parweld xp8 200a torch. I only had 0.8 wire at hand so went to local welding supply shop to get 0.8 tips as welder comes set up for 1.0mm. they had not seen these tips yet maybe a new design? So bought a roll of 1.0mm wire and came back and done a google/eBay search on the tips. Was shocked at the price of consumables for this torch. Only seam to be available genuine parweld at the moment.

Now I started the welder up for the first test weld on 2.5mm sheet. Set it in synergic mode and away I went. Now I would never have considered myself a good welder but I can stick things together with good penetration it just wouldn't have looked the part. But look at how neat and smooth the first weld it put out. No spatter in sight even tho its rusty sheet.

The oily scratched camera lens on my phone doesn't do it justice lol. Its better lookin real life.

Now it could have done with a bit more heat but you can trim the synergic settings.

Have done a quite a few more welds after this on the same sheet and 1mm sheet. Haven't had a chance to get trying good heavy stuff yet but so far I'm well impressed with it.

Only other point let's it down a bit is once you switch off synergic mode into normal mode the display where the amps were showen changes to display wire feed speed. You have to sort of guess the correlation between wfs/amps. Maybe with a bit of use I'd get the hang of it.

Next thing is to get trying out the tig. Just out of interest can you get a tig torch that plugs into euro connection so I can control the gas and current switch?

Now on to the price.

I don't know if I'm allowed names on here, if not then mods delete this part.

I ordered online from welding supplies direct and done a search for discount codes and found 10% discount code on there Facebook page (PROMO10)

The original price was 888plus so saved 106 quid with the code.

Hope this is helps anyone who couldn't find any info on this welder. I will update if I find any problems.

hope alls well with it, let me know if you've any questions about it at all

hope alls well with it, let me know if you've any questions about it at all