Piero

Member

- Messages

- 1,396

- Location

- Uk

Hi Guys

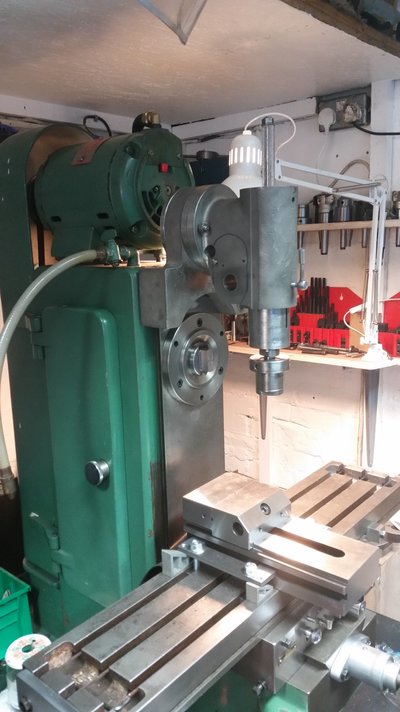

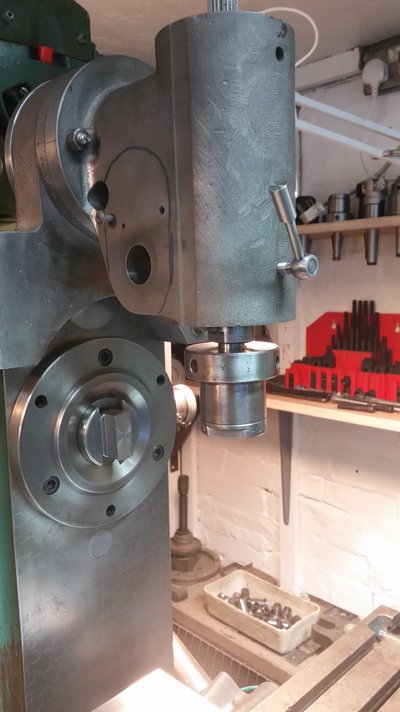

After a VERY long time, (to many other jobs) I have finaly compleated the full rebuild of a Tom Senior S head or quill head as some call it

I have searched all over the internet but cant find the differant speeds this thing can do

The lathe website was not interaly usfull

does and one know for certain ????

Ta

After a VERY long time, (to many other jobs) I have finaly compleated the full rebuild of a Tom Senior S head or quill head as some call it

I have searched all over the internet but cant find the differant speeds this thing can do

The lathe website was not interaly usfull

does and one know for certain ????

Ta

I renovated my Tom Senior light vertical a few years ago, apart from the head which is on my to do list.....

I renovated my Tom Senior light vertical a few years ago, apart from the head which is on my to do list.....