Hi guys,

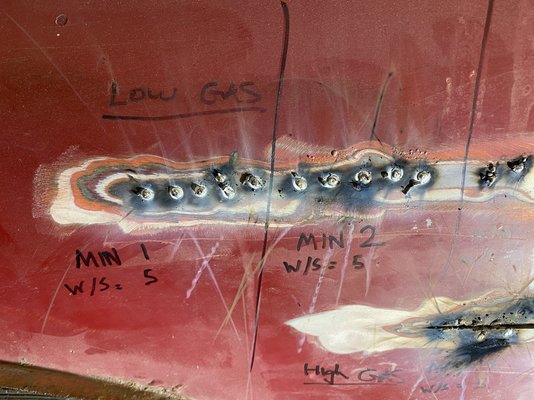

I’ve done a few quick test tack welds, on the rear quarter panel that’s coming off, what one do you think is near the mark (if any) I’m using a Clarke mig 130 en

It doesn’t have much in the way of settings. W/s is wire speed, it has min 1 or 2 and max 1 or 2, I’m using Argon gas, 0.8 wire.

I think anything on max will burn through on thinner stuff? and I’d say wire speed around 5 seems the sweet spot. Many thanks

I’ve done a few quick test tack welds, on the rear quarter panel that’s coming off, what one do you think is near the mark (if any) I’m using a Clarke mig 130 en

It doesn’t have much in the way of settings. W/s is wire speed, it has min 1 or 2 and max 1 or 2, I’m using Argon gas, 0.8 wire.

I think anything on max will burn through on thinner stuff? and I’d say wire speed around 5 seems the sweet spot. Many thanks