Shedendman

Member

- Messages

- 5,201

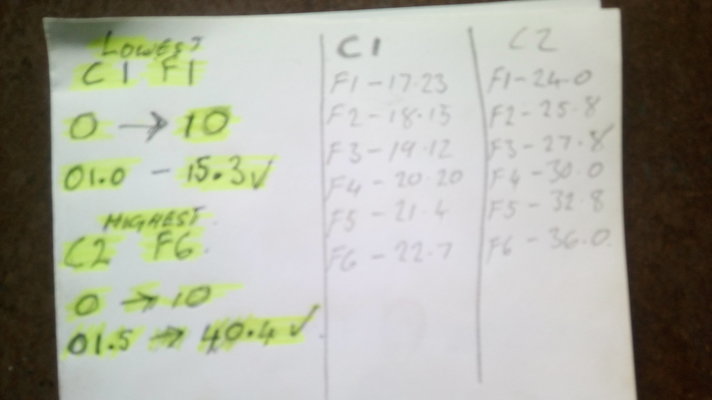

Right here goes,i seem to have to ramp up the wire speed on the dial further than i think i ought to, to get decent speed.

I get no movement when dials on 1(no probs) moving it clockwise its not until its at say 3/4 i get some movement,but way to slow, 5 through to 7 bit faster but still not enough(well just about) for the lowest welding setting to get a weld.

I'm now on 8-9 on the dial for whats required,it goes to 10,this is all on settings course 1 fine 1/2

This of course is under load ie pulling 0.8 wire off a 15kg reel down a 4mt torch lead

Off load i've tried it and seems to me as above i'm still getting the same motor speed.

Make sense so far?

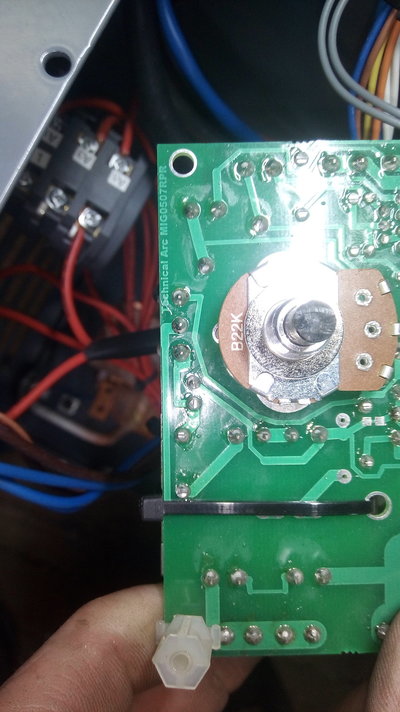

So what we talking here, duff potentiometer? Wire feed motor? or summit else

Reading around i see it can be tested,can this be done while still on the board or does it have to be removed?

Photo of the said thing

Just to add 1 more thing,on course 2 settings it does move faster as i go through the dial,but i cant use C2 thats way to much juice

Thanks chaps

I get no movement when dials on 1(no probs) moving it clockwise its not until its at say 3/4 i get some movement,but way to slow, 5 through to 7 bit faster but still not enough(well just about) for the lowest welding setting to get a weld.

I'm now on 8-9 on the dial for whats required,it goes to 10,this is all on settings course 1 fine 1/2

This of course is under load ie pulling 0.8 wire off a 15kg reel down a 4mt torch lead

Off load i've tried it and seems to me as above i'm still getting the same motor speed.

Make sense so far?

So what we talking here, duff potentiometer? Wire feed motor? or summit else

Reading around i see it can be tested,can this be done while still on the board or does it have to be removed?

Photo of the said thing

Just to add 1 more thing,on course 2 settings it does move faster as i go through the dial,but i cant use C2 thats way to much juice

Thanks chaps

,things totally different

,things totally different