Paul.

Moderator

- Messages

- 7,052

- Location

- Northampton. UK

Been making six stainless steel cages for a local company, these will be used to quarantine rejected product on a production line.

First a cutting up session, quite a few pieces of 30 x 30 angle and 30 x 30 box, and a load of stainless weldmesh to prepare,

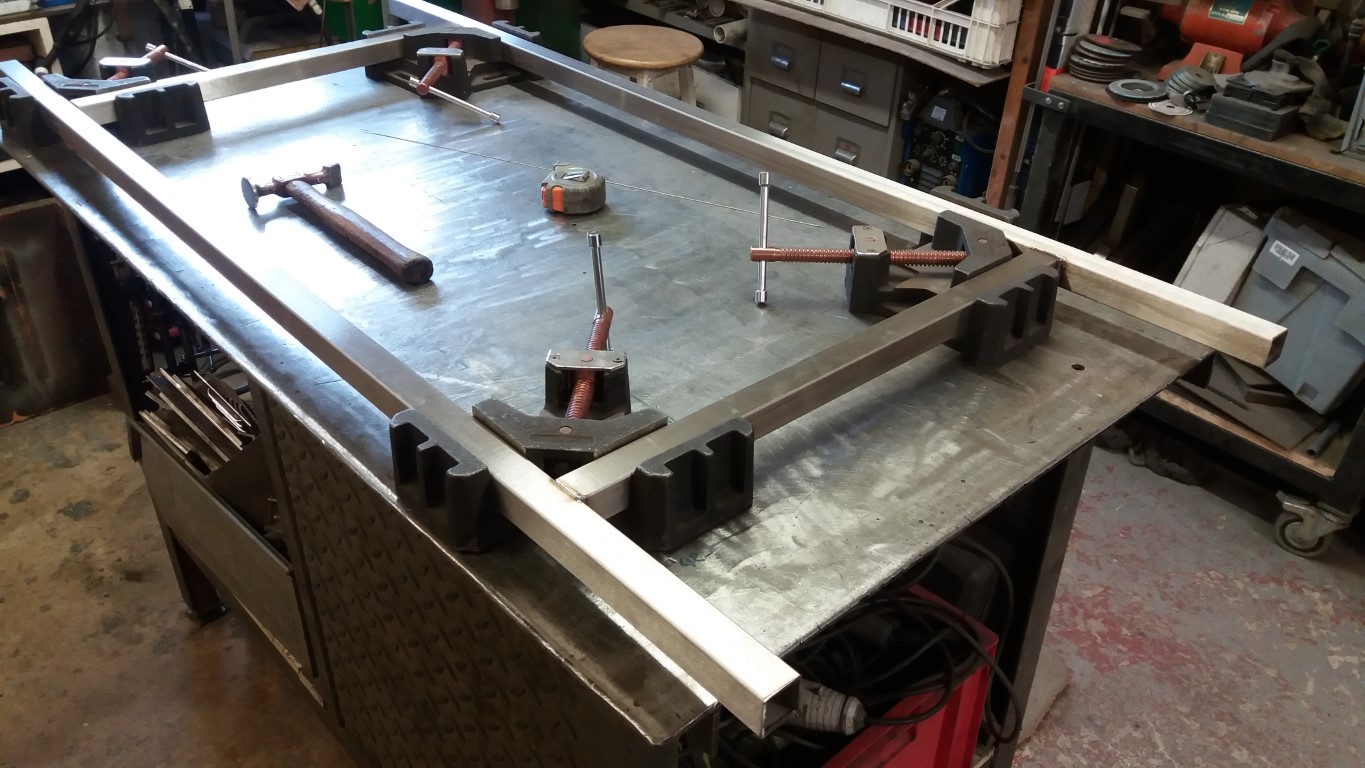

Some parts mitred using the chop saw, and then welded up into what will be the tops of the cages, its a box section frame with an inner angle frame to carry the mesh

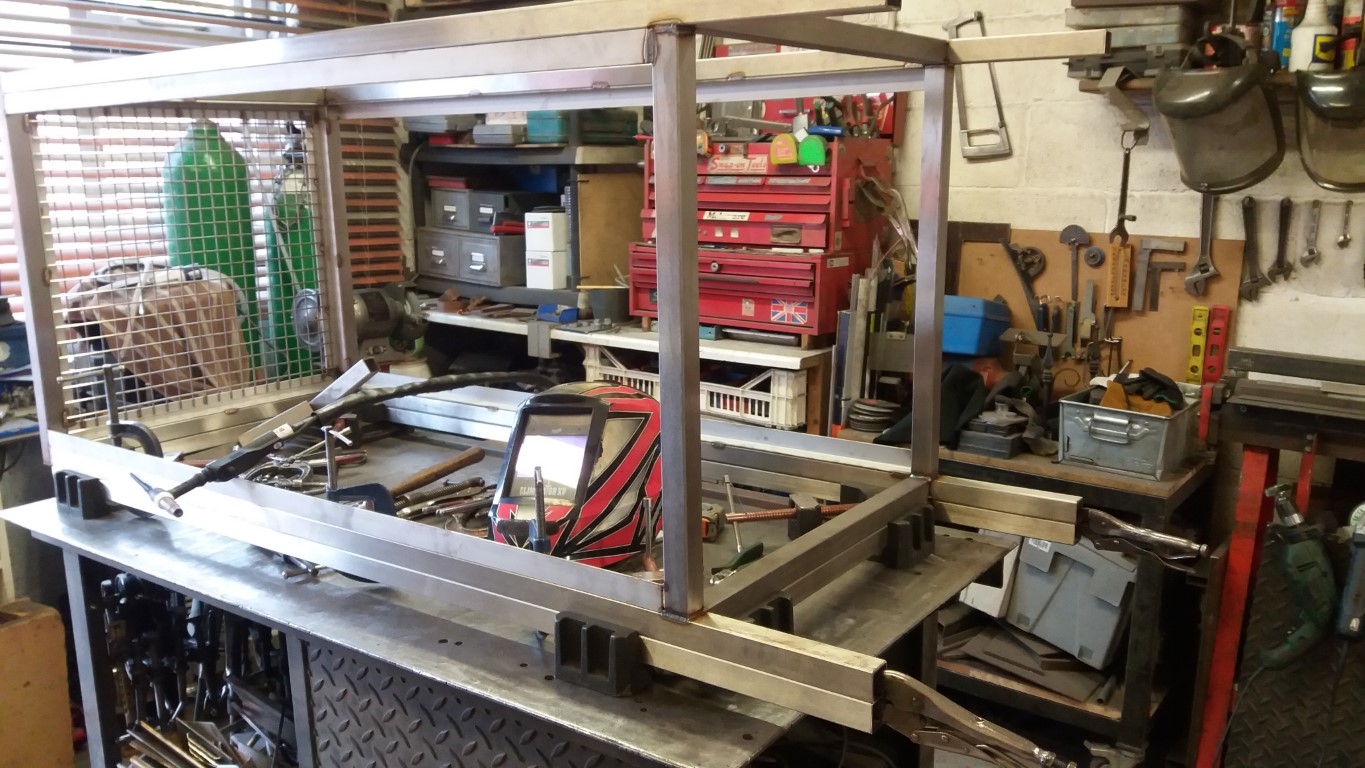

Then weld up the side frames,

And the door frames

I then used an assembled side frame in the corner clamps as a fixture to build the cages,

A laser cut plate with a nut welded on makes a mounting for a single bolt fixing castor, held in place for welding here with my endplateholderonner.

And the cages built and the mesh tacked in, I used the mig with stainless wire to fix the mesh, just used argoshield 5, that's why the welds are a bit sooty, but I'm not buying a bottle of tri mix just for one job, it'll clean up later

First a cutting up session, quite a few pieces of 30 x 30 angle and 30 x 30 box, and a load of stainless weldmesh to prepare,

Some parts mitred using the chop saw, and then welded up into what will be the tops of the cages, its a box section frame with an inner angle frame to carry the mesh

Then weld up the side frames,

And the door frames

I then used an assembled side frame in the corner clamps as a fixture to build the cages,

A laser cut plate with a nut welded on makes a mounting for a single bolt fixing castor, held in place for welding here with my endplateholderonner.

And the cages built and the mesh tacked in, I used the mig with stainless wire to fix the mesh, just used argoshield 5, that's why the welds are a bit sooty, but I'm not buying a bottle of tri mix just for one job, it'll clean up later

its things like that make it so much easier \ quicker

its things like that make it so much easier \ quicker