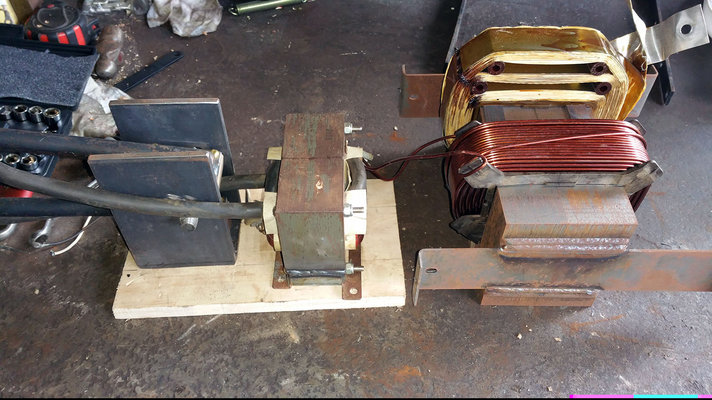

Has any of you guys made a spot welder using a microwave transformer with any success ? got any pics or materials list ?

Iv watched a good few youtube vids seems to be a fair few different methods.

I'm wanting to join some 0.9 mild steel and it don't want a great slugs of weld on it

Iv watched a good few youtube vids seems to be a fair few different methods.

I'm wanting to join some 0.9 mild steel and it don't want a great slugs of weld on it