Hi. I'm new to welding and recently acquired 180A MIG from R-Tech. I'm trying to ma

ke spot welds on 1,2mm sheet and for some reason can't get proper penetration. I cleaned mill scale and tried various combination of voltage/wire speed settings but my welds won't go through on other side. As experiment I've tried to set voltage to max to burn hole in test piece but for some reason my welder wasn't able to do that. I'm using it with gas. Have you got any ideas?

ke spot welds on 1,2mm sheet and for some reason can't get proper penetration. I cleaned mill scale and tried various combination of voltage/wire speed settings but my welds won't go through on other side. As experiment I've tried to set voltage to max to burn hole in test piece but for some reason my welder wasn't able to do that. I'm using it with gas. Have you got any ideas?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spot weld penetration problem

- Thread starter JacobKot

- Start date

mike 109444

Member

- Messages

- 4,671

Wire diameter ? (0.6 maybe)

mike 109444

Member

- Messages

- 4,671

You'll get more amps in with 0.8 wire AND by keeping the wire in one spot you are just pilling the wire up and the heat is going into the pile.

See what happens when you run a bead and you should find that the heat will gradually build up in and around the weld pool and the heat affected zone (either side of the bead) will get wider as you go along hence why when welding car bodywork it pays t do it in very short beads or a series of tacks. Known as the "thin metal technique".

See what happens when you run a bead and you should find that the heat will gradually build up in and around the weld pool and the heat affected zone (either side of the bead) will get wider as you go along hence why when welding car bodywork it pays t do it in very short beads or a series of tacks. Known as the "thin metal technique".

Alan Reynolds

Member

- Messages

- 1,269

When I read the title I assumed you were joining two pieces. If that is what you need to do, I usually drill a hole in the top piece and fill the hole with a spot from the mig.

Hi. I'm new to welding and recently acquired 180A MIG from Rtech. I'm trying to make spot welds on 1,2mm sheet and for some reason can't get proper penetration. As experiment I've tried to set voltage to max to burn hole in test piece but for some reason my welder wasn't able to do that.

With a MIG welder you can only simulate spot welds. Are you planing to drill or punch a hole in the upper sheet? That is known as plug welding. It is best to make the hole 8mm diameter. Clamp the sheets together very tightly before welding. I don't see a second sheet - are you just practising on the "lower" sheet? For 1.2mm + 1.2mm you will need about 80 Amps. Plug welding isn't easy - why have you chosen this method, what are you working on?

A 180A machine set to max should melt straight through 1.2mm. When you say "acquired" a 180A Rtech, is it new and are you sure it is working correctly? Are you attaching the work return cable ( "Earth" clamp ) directly to the workpiece? Could you post some photos of just plain straight beads on clean sheet steel?

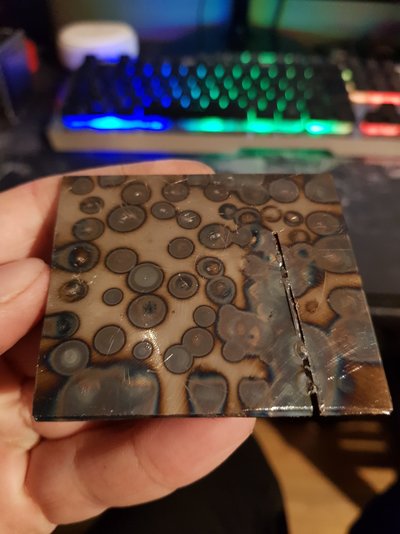

I'm trying to get settings right before butt welding 2 panels. Welder is new however I can't compare it to any other one. Earth was connected to plate on which I put welded piece. I attached pictures of what I think you asked for. This time earth was connected directly to welded piece and I set machine to get that frying beacon sound.

daedalusminos

Member

- Messages

- 2,150

- Location

- Norwich

It would be best to let us know what sort of joint you're trying to achieve, ultimately the welder needs to be set up on the final joint.

mike 109444

Member

- Messages

- 4,671