Hi guys, first of all ace forum. Proper handy info to be had in here. I've been using one of the threads in here to convert my snap on 130 to euro torch and everything went pretty well up until the gas solenoid. I bought a kit from weld uk and they supplied me with a 48v gas solenoid.

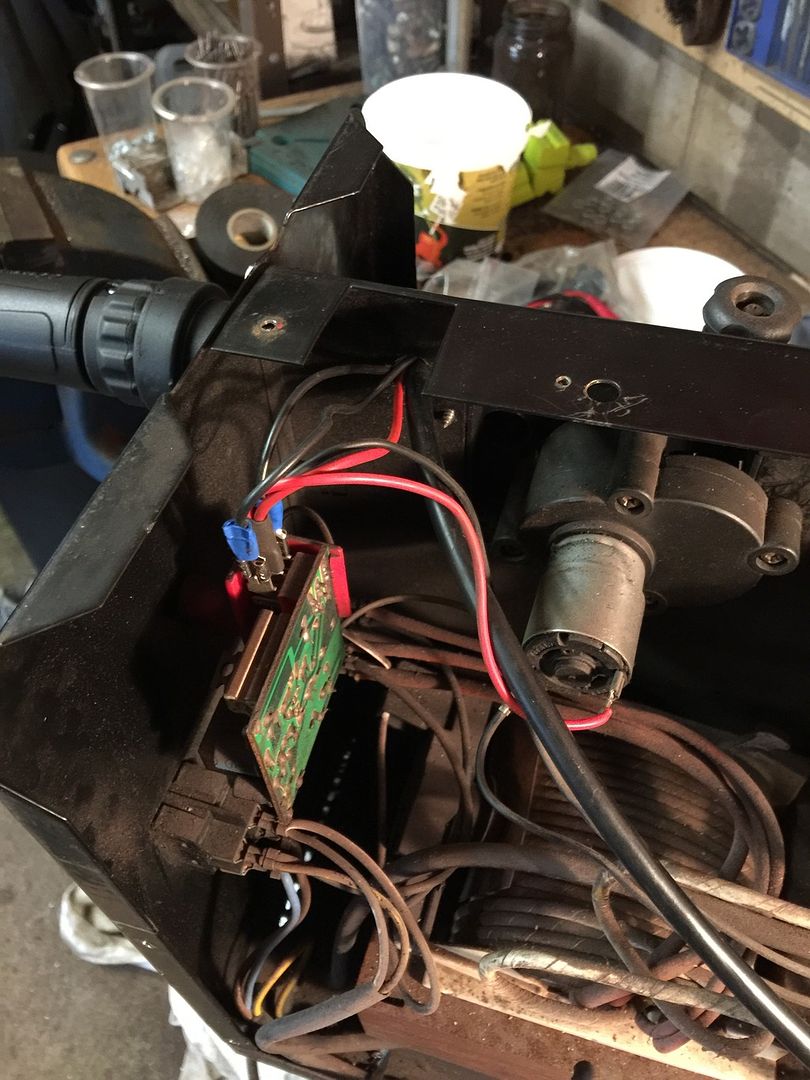

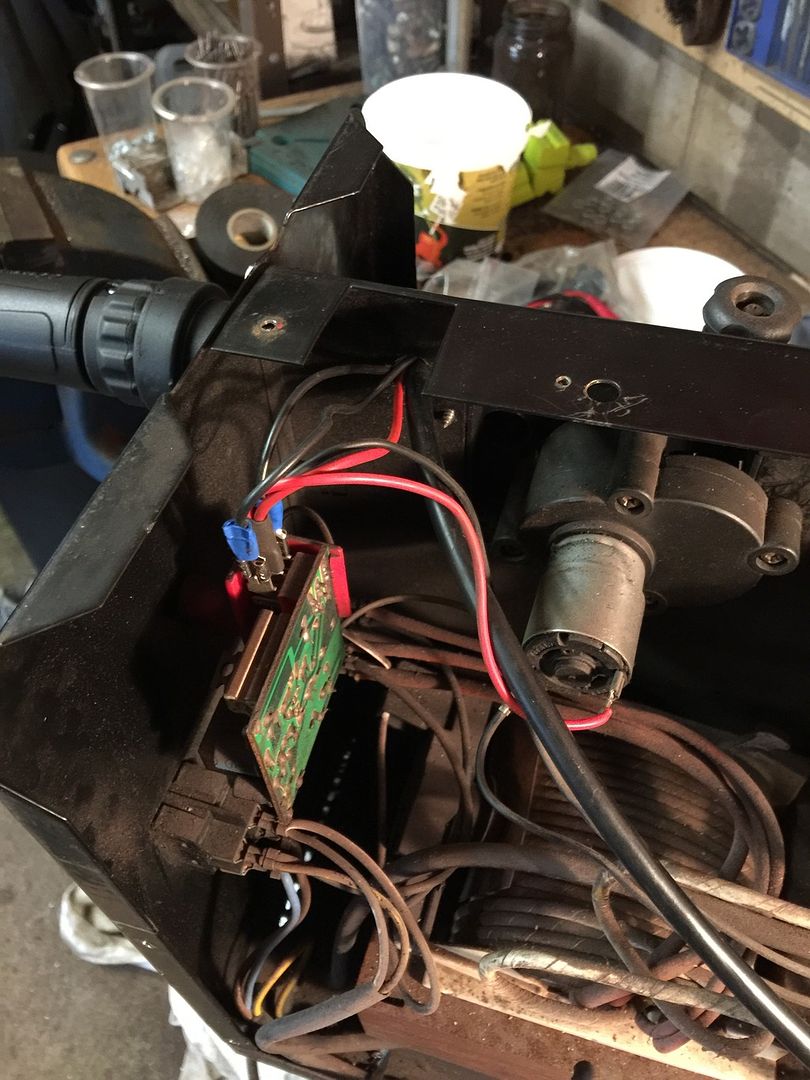

Here's the pics of how far I got, the torch feeds fine and it does a hideous gas less weld (that's how I Sussed out the gas solenoid wasn't playing the game)

I had connected the gas solenoid to the same wires as the motor but when I check wi the voltmeter I get 10v across the wires. Not enough clearly. So I'm assuming I've wired it up wrongly.

How I wired up the solenoid

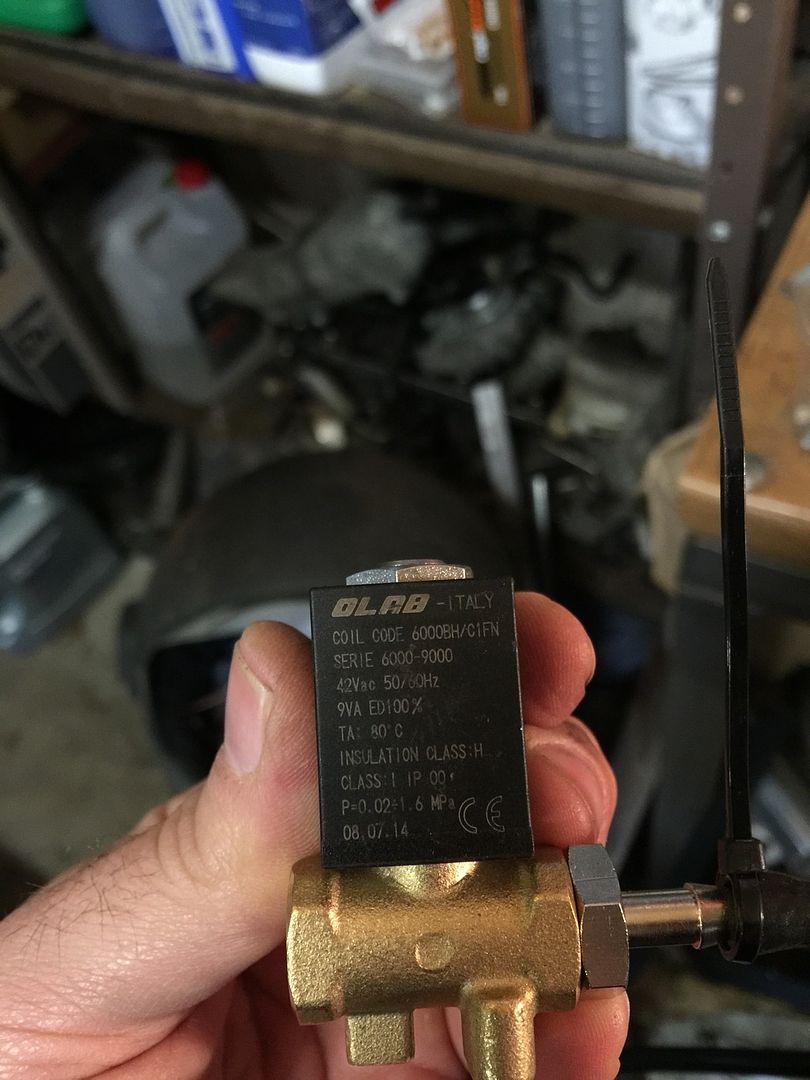

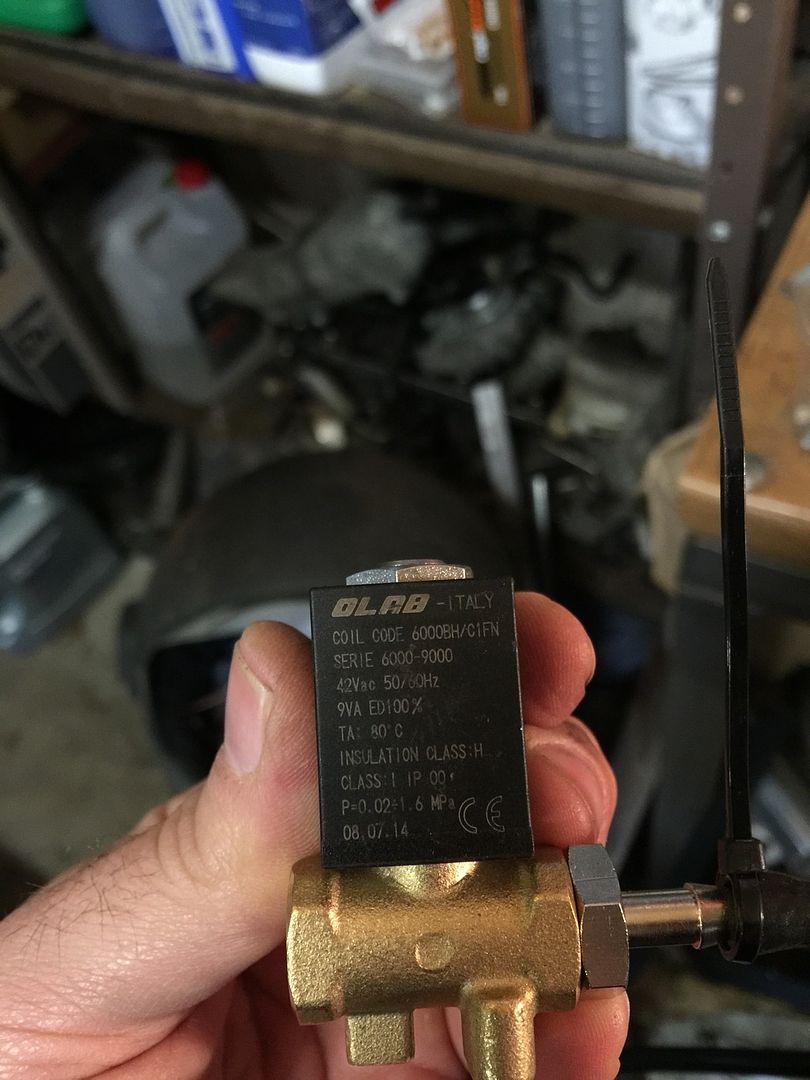

Solenoid I was supplied

Can anyone tell me how it should be wired up, pics would be epic. Thanks in advance

Here's the pics of how far I got, the torch feeds fine and it does a hideous gas less weld (that's how I Sussed out the gas solenoid wasn't playing the game)

I had connected the gas solenoid to the same wires as the motor but when I check wi the voltmeter I get 10v across the wires. Not enough clearly. So I'm assuming I've wired it up wrongly.

How I wired up the solenoid

Solenoid I was supplied

Can anyone tell me how it should be wired up, pics would be epic. Thanks in advance