northwest

Searching for the Holy Grail.........

- Messages

- 5,390

- Location

- Manchester UK

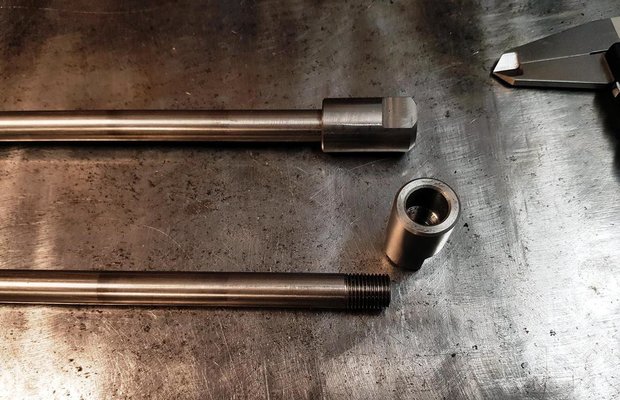

So I have decided to make a slide hammer instead of borrowing one when I need it.Funny things Slide Hammers, I am constantly amazed as to how many uses they really have. I am making two, one is for a friend of mine.

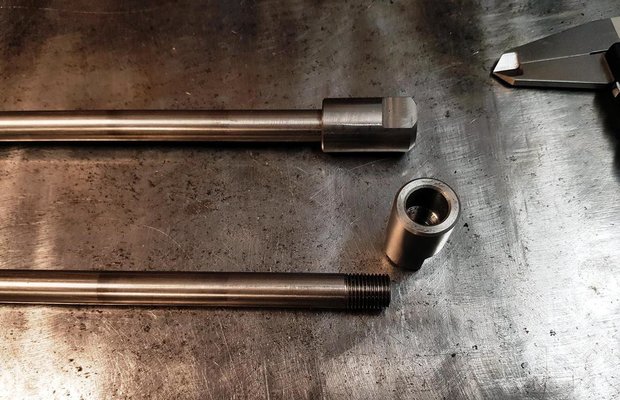

I would welcome any suggestions as to which Accessories I should make for the business end, in the photograph you can see a simple nut that will house a 6mm cap screw. I am going to buy a cheap ER25 collet chuck and cut it down then thread it or weld it to a piece of bar for the pulling end too as I have plenty of ER25 collets.

For the other end, the bit that traps the fleshy part of your hand when you are not paying attention, I was going to weld a plate on similar to the one on the slide hammer Snap On sell. Again, suggestions very welcome.

The thread is M12x1.25

I would welcome any suggestions as to which Accessories I should make for the business end, in the photograph you can see a simple nut that will house a 6mm cap screw. I am going to buy a cheap ER25 collet chuck and cut it down then thread it or weld it to a piece of bar for the pulling end too as I have plenty of ER25 collets.

For the other end, the bit that traps the fleshy part of your hand when you are not paying attention, I was going to weld a plate on similar to the one on the slide hammer Snap On sell. Again, suggestions very welcome.

The thread is M12x1.25