scottmk1

Forum Supporter

- Messages

- 1,967

- Location

- Scotland

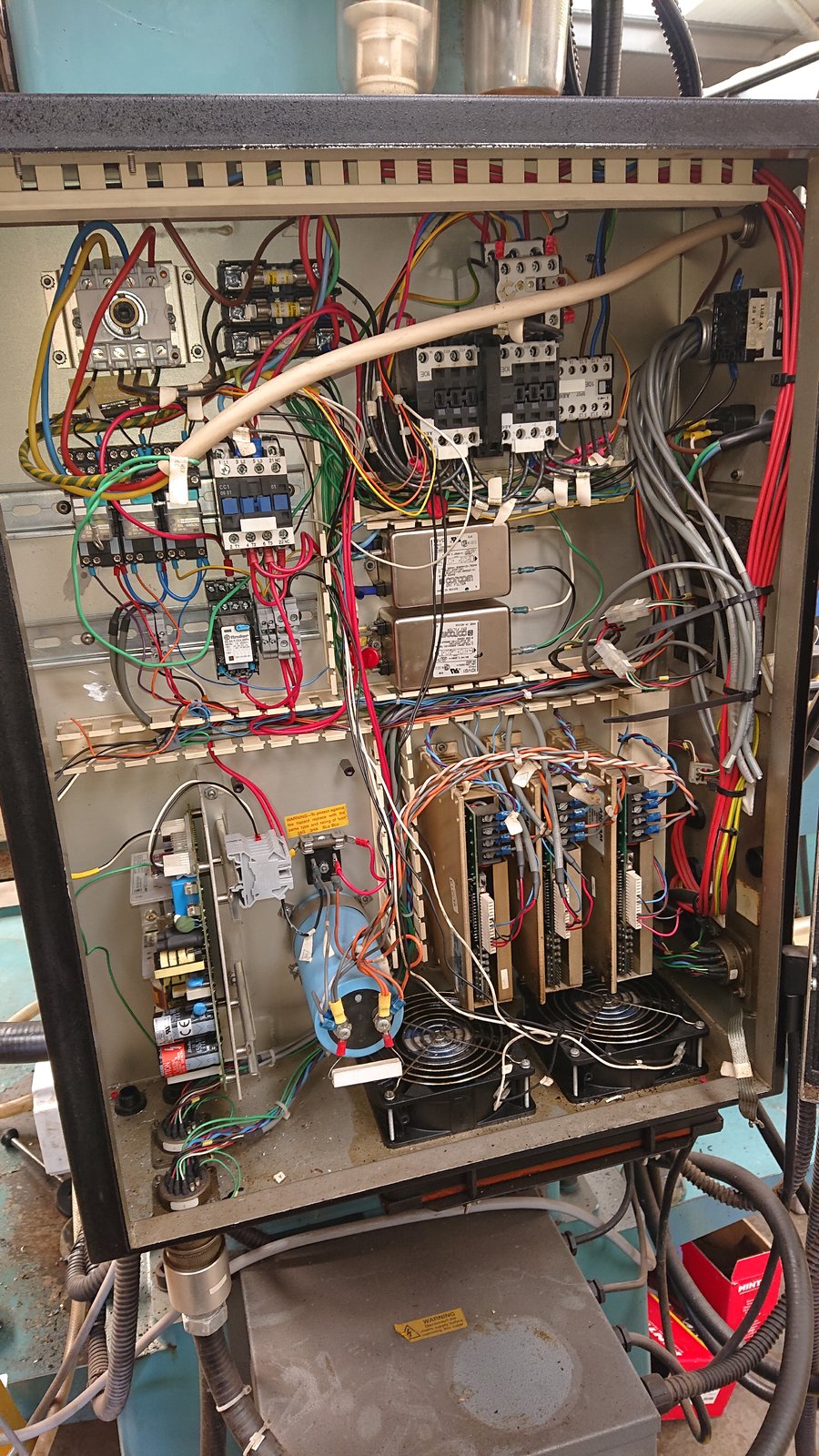

I have a Semco CNC bed mill, it has had a GSK 983 controller fitted but still uses the Anilam servo drives and boards. The wiring looks like a mess unfortunately, should have checked that before I bought it but there you go.

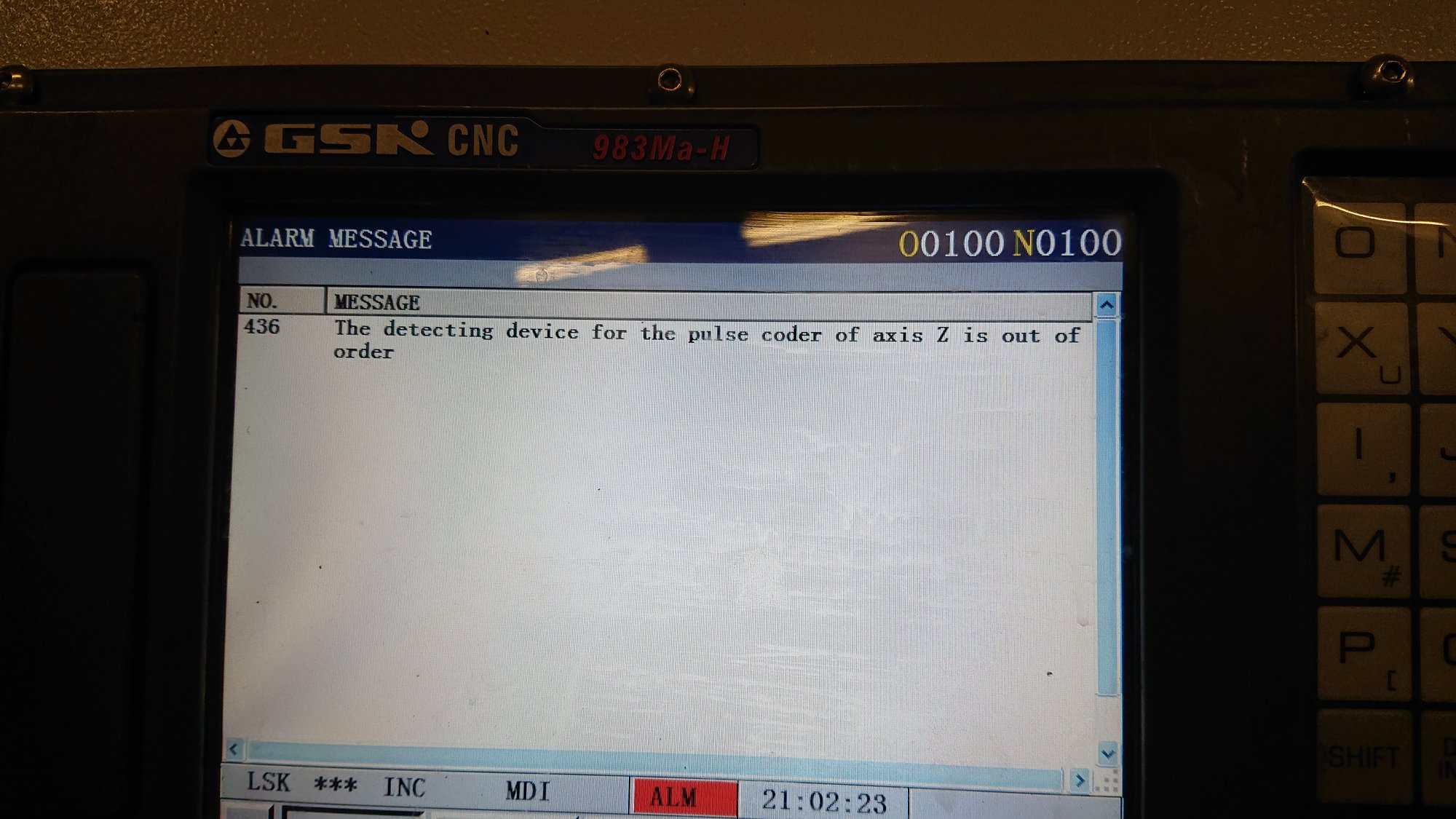

Anyway recently I fired it up and get alarms about the Z axis detecting device pulse encoder, and the Z axis motor is constantly turning. See the alarm below:

Where do I start with trouble shooting this?

Here is the cabinet on the back of the column:

Anyway recently I fired it up and get alarms about the Z axis detecting device pulse encoder, and the Z axis motor is constantly turning. See the alarm below:

Where do I start with trouble shooting this?

Here is the cabinet on the back of the column: