I have a mighty mig 190 and its just suddenly stopped wire feeding. It was working fine one day and then not the next. All you here is a clicking of a relay. Ive check the motor with a battery and thats fine. Thinking towards a knackered PCB. Any ideas on what to do?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sealey Mighty Mig 190

- Thread starter Montygti

- Start date

Hello and welcome to the Forum !

Is the relay that you can hear a small one on the PCB, or the large heavy-duty Contactor that controls power to the main welding transformer?

Apart from the wirefeed motor, does the gas solenoid valve operate, and can you get an arc at the end of the MIG wire?

Is the relay that you can hear a small one on the PCB, or the large heavy-duty Contactor that controls power to the main welding transformer?

Apart from the wirefeed motor, does the gas solenoid valve operate, and can you get an arc at the end of the MIG wire?

Ive had a look this afternoon. Ive got no wire feed, but you can hear the heavy duty contactor ticking. Also the gas solenoid doesnt operate and i cant get an arc at the end of the mig wire. Any suggestions or is it a case if in the bin. cheers

I think the main welding transformer is being switched on, but it's not providing any output. The next step would be to measure the AC output from the transformer secondary - should be two very thick copper or aluminium wires emerging from the transformer and bolted to the plates of the rectifier. Expect to see about 15 to 35 volts AC across those two wires, depending on the power range selected. If that is OK, then check for about the same DC voltage on the output side of the rectifier. That output will be two heavy cables, one going to the wirefeed assembly and the other to the Inductor or Choke ( looks like a transformer ).

The fact that the Contactor is pulling in means that you do have AC power, but there's nothing coming out of the transformer. They do fail, but seldom.

Have you tried all positions of the power range switch?

The Contactor could have corroded or burnt contacts internally, so that even tho' it is moving, there's no power being fed through. If there is a manual operating button in the centre, try pressing that in firmly, using an insulated screwdriver, with power on.

Trace the wiring and confirm that you have AC mains at the input and then at the output terminals of the Contactor.

Look for overheat thermo-switches glued to the transformer windings and/or the rectifier plates. They normally conduct across the two tags, but may be stuck in the "open-circuit" condition

Have you tried all positions of the power range switch?

The Contactor could have corroded or burnt contacts internally, so that even tho' it is moving, there's no power being fed through. If there is a manual operating button in the centre, try pressing that in firmly, using an insulated screwdriver, with power on.

Trace the wiring and confirm that you have AC mains at the input and then at the output terminals of the Contactor.

Look for overheat thermo-switches glued to the transformer windings and/or the rectifier plates. They normally conduct across the two tags, but may be stuck in the "open-circuit" condition

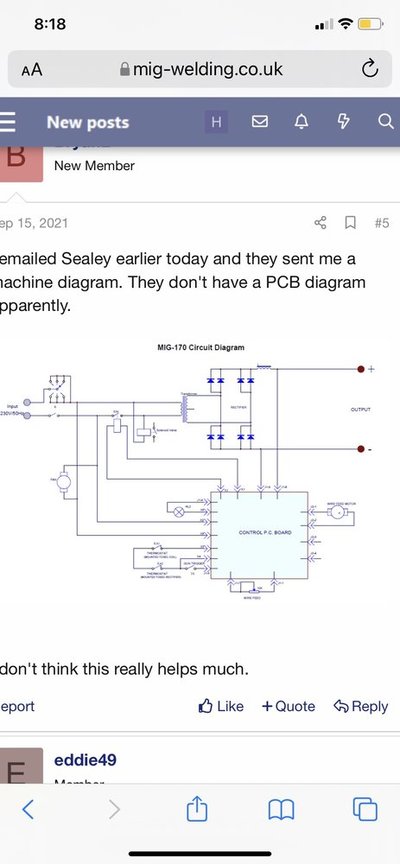

Well had another good look today and i think its going to be the skip for this as i cant figure it out. Thermo switch is ok. The thing that i cant work out is the contactor is operating but nothing seems to be coming out of it even to operate the gas solinoid. Ive taken it t pieces and cleaned all the contacts and its made no difference powers going in but nothing out. Trouble is the only place i can get a contactor is china so that could take a bit of time and dont know if its worth spending the cash. My other option is a repair shop but that could get expensive. I between that its the contactor or possible transformer as i know these some time go. I tried all posistion switches and still nothing. Is there a way to bypass the contactor or to test it properly. This also no continuity accros the spades of the contactor when i press the contactor by hand. But then again i dont actually know if im testing it right. This is a diagram of the contactor. Presumably that when i press contactor i should get continuity between pins 0 and pins 2, and then pins 1 and pins 6. This is the actual contactor. https://www.ebay.co.uk/itm/HLR6100-...487867?hash=item2f30ff1afb:g:Y7wAAOSwgENeEpz-

Any help is grately appreciated.

Any help is grately appreciated.

That is a strange Contactor to use on a MIG welder, never seen that type before.

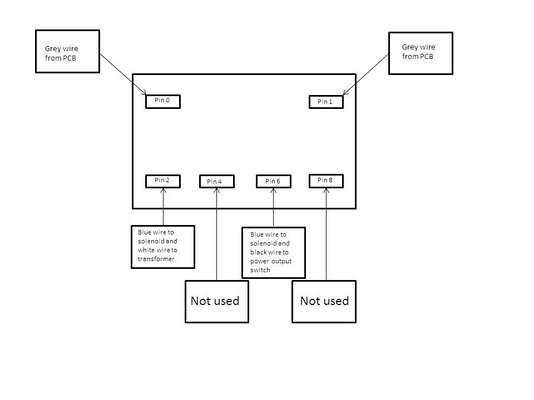

The relay coil, which apparently runs on 24v DC, should get power from the PCB on the two grey wires at Pins 0 and 1, when the torch trigger is pressed. It does click, so that must be OK.

The relay has two sets of contacts, which close when the coil gets 24v power or is manually operated, and they are 2 to 4 and 6 to 8. The outputs of these contacts are Pins 2 ( to solenoid, and to main transformer ) and 6 ( to solenoid, and to power range switch - probably then on to the transformer ). However, from the eBay listing for the contactor, the inputs to those two sets of contacts are Pins 4 and 8, and yet they are not used ? There should be AC mains going in to 4 and 8. Are there any "spare" wires with push-on tags lying loose in the area near the relay?

The relay coil, which apparently runs on 24v DC, should get power from the PCB on the two grey wires at Pins 0 and 1, when the torch trigger is pressed. It does click, so that must be OK.

The relay has two sets of contacts, which close when the coil gets 24v power or is manually operated, and they are 2 to 4 and 6 to 8. The outputs of these contacts are Pins 2 ( to solenoid, and to main transformer ) and 6 ( to solenoid, and to power range switch - probably then on to the transformer ). However, from the eBay listing for the contactor, the inputs to those two sets of contacts are Pins 4 and 8, and yet they are not used ? There should be AC mains going in to 4 and 8. Are there any "spare" wires with push-on tags lying loose in the area near the relay?

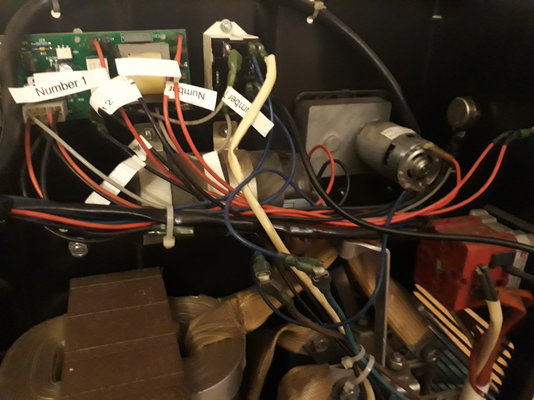

Thanks eddie49 for the quick reply and you are right and the answer was staring me right in the face and you can see exactually what has caused it. The main power lead coming into the welder has obviously got caught when someone has tried to wheel it away and it had pulled the wore and both connectors out of the contactor and pulled them down so there wasnt enough wire to be abe to reconnect them up. So loosened the grommit pulled them back and plug them and all is now good with the welder. You can see them in the photo half way down the screen, because they were all the way down there i just thought they were joining two wires until i read your message. So a big thankyou from me and the welder lives on.

Thank you for the update. That is a great result !

From your photo I can see that the push-on tags on the mains lead were siamesed with the wires that run the small transformer on the PCB, which would explain why power was still available to make the relay click.

I am pleased that the welder is working again now.

From your photo I can see that the push-on tags on the mains lead were siamesed with the wires that run the small transformer on the PCB, which would explain why power was still available to make the relay click.

I am pleased that the welder is working again now.

The temperature warning light is often in parallel with the thermal sensor. With the sensor normally closed, the light will be shorted and not on. If the sensor overheats and opens, the light bulb will see the voltage across the open switch contacts, and light up.

Thanks Eddie - I got two sensors - and a extra wire - from what I can gather they should be two wires on x4 terminal - for the life of me I can’t work it outThe temperature warning light is often in parallel with the thermal sensor. With the sensor normally closed, the light will be shorted and not on. If the sensor overheats and opens, the light bulb will see the voltage across the open switch contacts, and light up.

Found this off another post you helped with - x5 going to coil sensor -Thanks Eddie - I got two sensors - and a extra wire - from what I can gather they should be two wires on x4 terminal - for the life of me I can’t work it out

Then from that sensor to the rectifier sensor

Then from that sensor a torch switch wire

Return torch switch going too x4 with j1 ??