angellonewolf

Member

- Messages

- 8,115

- Location

- bristol england

I thought I'd add an review to hopefully help a few of the new buyers thinking of buying a cheaper range of welder, I have picked up a Cosmo 130 gas and gasless welder a few years old I'd guess 8 years at the looks of the condition of the unit and as ive paid a cheap price just to see if one of the cheaper units hinder or help your start off intro in to welding if you are going to buy a cheapy unit to start with

now bear in mind im not a pro welder just a person thats been on the site for a only a few years have come a little way (not that far) and started out with an very old migmate 100 (one of the older units that seam to be not great but passable for starting off)and gone through 6 units before getting a clark 160en in good condition and can weld thin .6mm metal to 4mm to fair weld

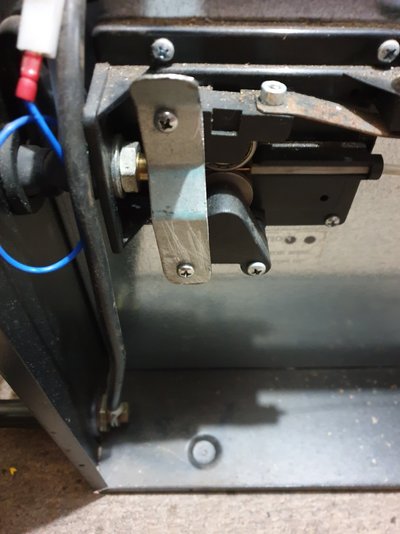

any how this is much of a review unless im talking about the unit im doing a review about so back to it so first off the reason i got the welder was he could not get a good continus weld out of it the first thing i noted is that it has what seams a plastic feed unit and no matter what i done with the tension on the wire feed did not get a good feed and from looking on the fourm for the last few years did a sip repair

see photo below

now bear in mind im not a pro welder just a person thats been on the site for a only a few years have come a little way (not that far) and started out with an very old migmate 100 (one of the older units that seam to be not great but passable for starting off)and gone through 6 units before getting a clark 160en in good condition and can weld thin .6mm metal to 4mm to fair weld

any how this is much of a review unless im talking about the unit im doing a review about so back to it so first off the reason i got the welder was he could not get a good continus weld out of it the first thing i noted is that it has what seams a plastic feed unit and no matter what i done with the tension on the wire feed did not get a good feed and from looking on the fourm for the last few years did a sip repair

see photo below

Last edited: