Hi all

I turned out a pretty shoddy weld the other day before realising that I had run out of gas

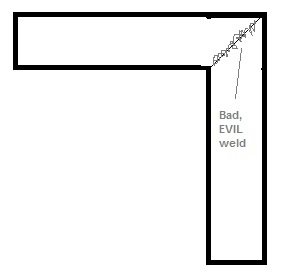

It's joining two pieces of box section at a 90 degree angle, it is a mitre join (cut across at 45 degrees). It seems strong enough (hammer test) but looks porous and I don't really want a bad weld on something that I'm going to be sleeping on (it is a futon frame).

Might seem like a really dumb question, but can I just grind the weld flat and then lay a new one over the top to improve the strength? Or do i need to cut the whole thing apart and start again? (Major pain).

What do pros do in this situation? (Apart from not doing it in the first place, of course).

I don't have any pictures on me of the weld itself but I've attached a paint diagram so you can see what sort of join it is.

Cheers and sorry for asking so many stupid questions.

I turned out a pretty shoddy weld the other day before realising that I had run out of gas

It's joining two pieces of box section at a 90 degree angle, it is a mitre join (cut across at 45 degrees). It seems strong enough (hammer test) but looks porous and I don't really want a bad weld on something that I'm going to be sleeping on (it is a futon frame).

Might seem like a really dumb question, but can I just grind the weld flat and then lay a new one over the top to improve the strength? Or do i need to cut the whole thing apart and start again? (Major pain).

What do pros do in this situation? (Apart from not doing it in the first place, of course).

I don't have any pictures on me of the weld itself but I've attached a paint diagram so you can see what sort of join it is.

Cheers and sorry for asking so many stupid questions.