RonA

specialist in repairing sealed for life equipment

- Messages

- 1,939

- Location

- Stockton on Tees, UK

I've just gotten round to fixing up the Q&S power hacksaw I've had lying around in my workshop for some time since I purchased it as a scrap item from my former employment.

After fabricating a new motor bedplate it's now resplendent with a single phase motor, new pulley & v belt.

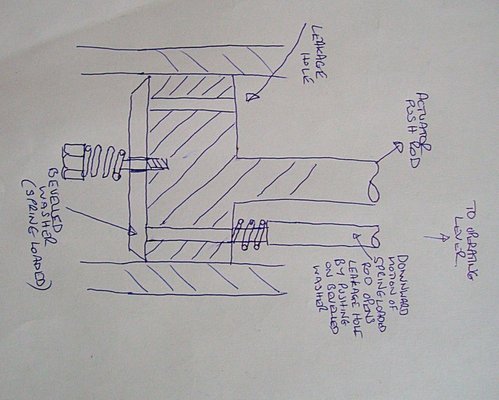

However, after lowering the blade onto the worKipiece & starting the saw, the hydraulic feed cylinder is jacking the saws frame upwards away from cutting & no matter where I position the the feed operating handle it refuses to lower whilst the motor is running.

Anybody had experience of this make of saw or better still the operating instructions.

Thanks in anticipation

RonA

After fabricating a new motor bedplate it's now resplendent with a single phase motor, new pulley & v belt.

However, after lowering the blade onto the worKipiece & starting the saw, the hydraulic feed cylinder is jacking the saws frame upwards away from cutting & no matter where I position the the feed operating handle it refuses to lower whilst the motor is running.

Anybody had experience of this make of saw or better still the operating instructions.

Thanks in anticipation

RonA