Davek0974

****!, Drink!, Girls!

- Messages

- 918

- Location

- Hertfordshire

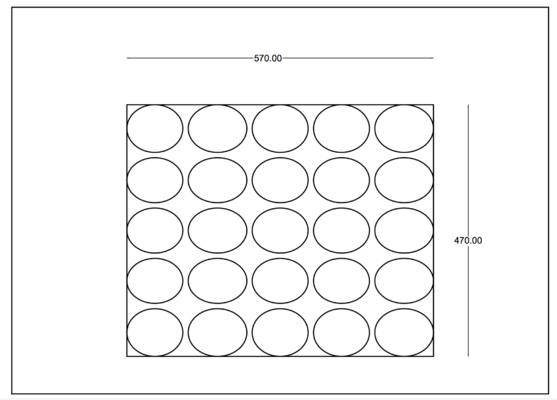

Started building a new booth for powder-coat, 1m x 1m x 1m

The four frames held on the front with clamps are doors, means i can save floor space when not in use and also keeps the dust and muck out of the booth.

Will be skinned with 0.9mm mild steel sheet when it arrives Monday.

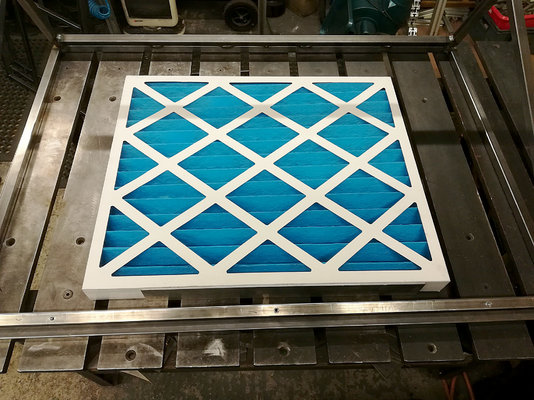

A 24" filter panel to go top/rear, venting through side wall panel.

Need to add centre struts to top/bottom and top/bottom doors to support skins.

Its a self-assembly design or it won't go out the door when i need it to

Coming along

The four frames held on the front with clamps are doors, means i can save floor space when not in use and also keeps the dust and muck out of the booth.

Will be skinned with 0.9mm mild steel sheet when it arrives Monday.

A 24" filter panel to go top/rear, venting through side wall panel.

Need to add centre struts to top/bottom and top/bottom doors to support skins.

Its a self-assembly design or it won't go out the door when i need it to

Coming along