after reading this thread about running a plasma cutter from a 13A plug

http://www.mig-welding.co.uk/forum/threads/can-i-cut-on-13amps.66649/#post-868580

I bought one of these

http://www.ebay.co.uk/itm/161778007256

so my first impressions were on how short the leads were, the power supply lead is 75cm long, the torch lead is 2.5m long (including the torch) and the earth lead is just under 1.5m long.

The instruction book supplied was for a CUT 50 plasma without the pilot arc.

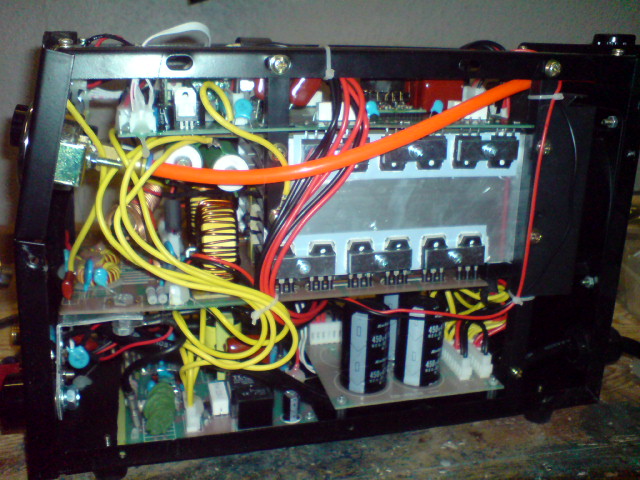

and here's what the inside looks like

it doesnt really show it in that picture but it looks like every cable connector is held together with glue from a hot glue gun.

I decided to ditch the earth lead supplied and used the one for my Tig welder, but as that has a large Dinse plug I got an adaptor for it

http://www.ebay.co.uk/itm/151764804618

and this is the pilot arc in operation

and the torch supplied is an AG60 torch, so consumables are readily available (on ebay at least).

it seems to work fine at 35A from a 13A plug, but blows fuses at 40A, so I started play with it set to 35amps. I did try with air pressures from 50psi to 70psi and found it was miles better at 50psi. at 70psi, its like the plasma was blown out and it would only work intermitantly, so reducing the pressure seemed to make it work better too. at 70psi it was struggling to cut 4mm thick steel but at 50psi it was cutting through 6mm steel.

I only really planned to get it for use for cutting metal upto 3mm thick, including rough cutting 0.9mm sheet steel before final trimming with some snips. the standard nozzle is 1.2mm wide for use upto 60 amps, so I've ordered some 0.9mm nozzles for upto 40 amps, so may produce a better cut on thinner section metal, but only time will tell.

I'll let you know how I get on with this later.

slightly off topic, but I was getting fed up with the number of hoses and cables I have, so I ended up screwing some large hooks into a beam in the roof of my garage, now they are easy to get to without getting tangled up. wish I'd done that years ago.

http://www.mig-welding.co.uk/forum/threads/can-i-cut-on-13amps.66649/#post-868580

I bought one of these

http://www.ebay.co.uk/itm/161778007256

so my first impressions were on how short the leads were, the power supply lead is 75cm long, the torch lead is 2.5m long (including the torch) and the earth lead is just under 1.5m long.

The instruction book supplied was for a CUT 50 plasma without the pilot arc.

and here's what the inside looks like

it doesnt really show it in that picture but it looks like every cable connector is held together with glue from a hot glue gun.

I decided to ditch the earth lead supplied and used the one for my Tig welder, but as that has a large Dinse plug I got an adaptor for it

http://www.ebay.co.uk/itm/151764804618

and this is the pilot arc in operation

and the torch supplied is an AG60 torch, so consumables are readily available (on ebay at least).

it seems to work fine at 35A from a 13A plug, but blows fuses at 40A, so I started play with it set to 35amps. I did try with air pressures from 50psi to 70psi and found it was miles better at 50psi. at 70psi, its like the plasma was blown out and it would only work intermitantly, so reducing the pressure seemed to make it work better too. at 70psi it was struggling to cut 4mm thick steel but at 50psi it was cutting through 6mm steel.

I only really planned to get it for use for cutting metal upto 3mm thick, including rough cutting 0.9mm sheet steel before final trimming with some snips. the standard nozzle is 1.2mm wide for use upto 60 amps, so I've ordered some 0.9mm nozzles for upto 40 amps, so may produce a better cut on thinner section metal, but only time will tell.

I'll let you know how I get on with this later.

slightly off topic, but I was getting fed up with the number of hoses and cables I have, so I ended up screwing some large hooks into a beam in the roof of my garage, now they are easy to get to without getting tangled up. wish I'd done that years ago.

(hopefully not your one, you've just got it

(hopefully not your one, you've just got it  )

)

and even more puzzling is to get them level.

and even more puzzling is to get them level.