You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

only 2nd time of mig welding

- Thread starter andy28

- Start date

- Messages

- 17,009

There's no point in saying otherwise as it won't help you to learn...... they're awful!

Looks like you're travelling way too fast, slowing it down will allow you to run continuous beads rather than intermittent blobs.

How thick is that steel and what machine are you using?

Have you looked at our tutorials?

Looks like you're travelling way too fast, slowing it down will allow you to run continuous beads rather than intermittent blobs.

How thick is that steel and what machine are you using?

Have you looked at our tutorials?

daedalusminos

Member

- Messages

- 2,149

- Location

- Norwich

Oh dear, what was the first time like?

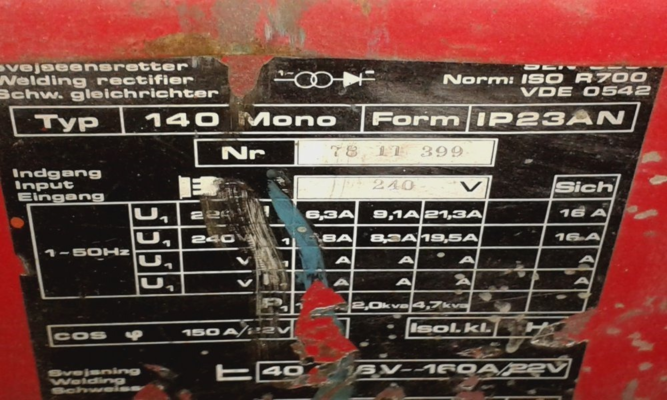

What machine is it, gasless or gas, what gas?

Unsure on thickness....give us a rough idea

What machine is it, gasless or gas, what gas?

Unsure on thickness....give us a rough idea

daedalusminos

Member

- Messages

- 2,149

- Location

- Norwich

Check the wire isn't rusty, if so change it and the liner.

Clean your metal...both where welding and where the earth connects.

You'll need to be near max power setting for 3mm

Clean your metal...both where welding and where the earth connects.

You'll need to be near max power setting for 3mm

daedalusminos

Member

- Messages

- 2,149

- Location

- Norwich

postie jon

Member

- Messages

- 878

- Location

- Aberdeenshire, Scotland

dont be disheartened,everyone has or had to learn at some point, i will never forget my welding tutor at college on the 2nd day "looks like puppy sheet in the snow"....

andy28

Member

- Messages

- 156

mate my hands are not always very steady due to my disability ..Should have said, I agree with @Wozzaaah , looks like you're skating across the surface, do you have good view/steady hand?!

mate good point as I feel will get there in end..dont be disheartened,everyone has or had to learn at some point, i will never forget my welding tutor at college on the 2nd day "looks like puppy sheet in the snow"....

Use both hands on the torch to keep it steady. It is extremely important to be comfortable, rest your arms on the bench if you are able to. Don't be afraid of the sparks and the heat. Don't start moving straight away. Let a weld pool form and then slowly move the torch. I remember watching a mate trying to weld with no prior experience and it looked a lot like what you have produced. It's a slow deliberate movement with torch that you want to be aiming for.

postie jon

Member

- Messages

- 878

- Location

- Aberdeenshire, Scotland

shouldve gone to specksavers......I'm the only one seeing Clint Eastwood firing a gun to the left it seems. I actually thought this was an art piece.

andy28

Member

- Messages

- 156

thank you mate I get the point on movement think also will give her a service...Use both hands on the torch to keep it steady. It is extremely important to be comfortable, rest your arms on the bench if you are able to. Don't be afraid of the sparks and the heat. Don't start moving straight away. Let a weld pool form and then slowly move the torch. I remember watching a mate trying to weld with no prior experience and it looked a lot like what you have produced. It's a slow deliberate movement with torch that you want to be aiming for.

ajlelectronics

Forum Supporter

- Messages

- 8,599

- Location

- Gloucester, England

You still haven't cleaned the steel. You will not get good results until you do.

andy28

Member

- Messages

- 156

ok mate I get that..You still haven't cleaned the steel. You will not get good results until you do.

Rusty

Member

- Messages

- 600

andy28

Member

- Messages

- 156

thank you mate I feel getting there..Looking much better though

If you're right handed you can hold the gun in your right hand and then use your left hand to prop yourself up or steady your harm. However make sure you don't have your hands too close to the arc. I find having my elbow to the opposite hand holding the gun resting on the work surfacing that its hand resting on my gun hands arm helpful to keep me steady when welding.