Pigeon_Droppings

Member

- Messages

- 123

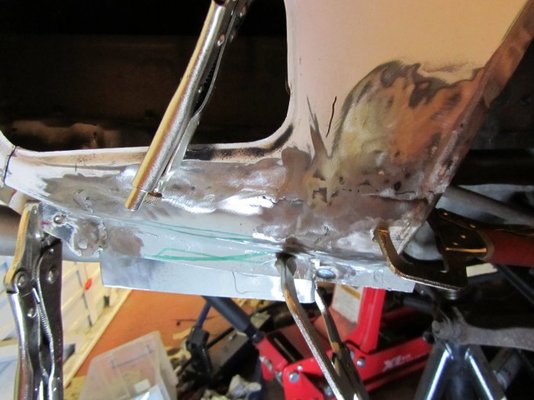

OK - decided to post my MR2 sill repair. Am new to MIG and also fabrication so please go easy on my efforts. Sill repair panels are not available for the MR2....toyota sell small repair sections at great expense so I had to come up with my own method of fabricating the sills. Am sure others have done this and it's probably not a new approach bbut it was new for me. The other alternative is to fit sills from a car which are a close match...from reading around this did not sound as easy as just sticking to the original shape.

As with all Jap cars ...the original intention was to just clean off the couple of rust bubbles and do a quick repair with a small patch (I can hear the more experienced repairers quietly laughing at the beginner)

As with all Jap cars ...the original intention was to just clean off the couple of rust bubbles and do a quick repair with a small patch (I can hear the more experienced repairers quietly laughing at the beginner)