Fazerruss

Member

- Messages

- 3,033

Just a little job I'm on with tonight.

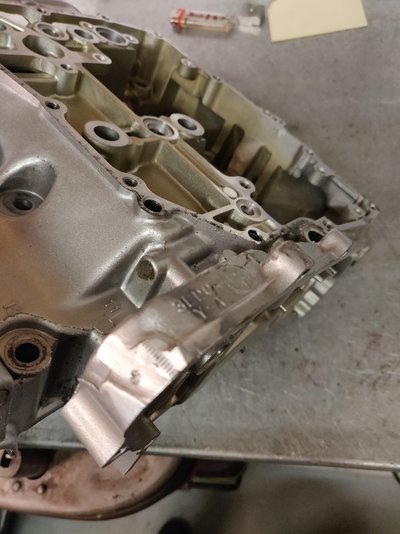

Yamaha TDM 850 broken starter motor mounting lug on crank case.

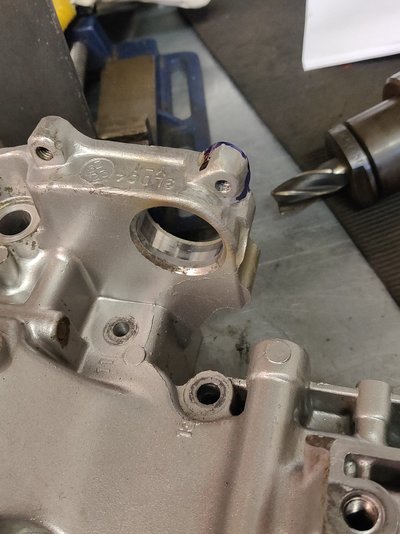

Here is the damage......

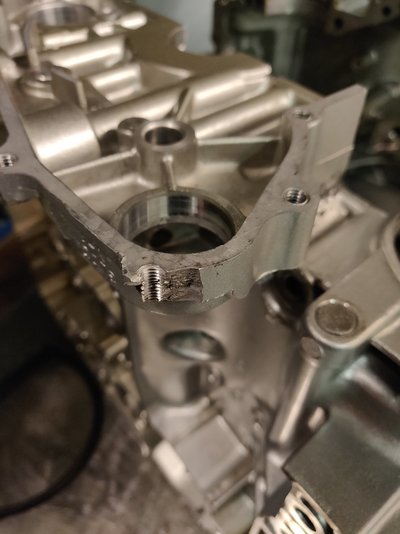

Cleaned up ready for Tig.....

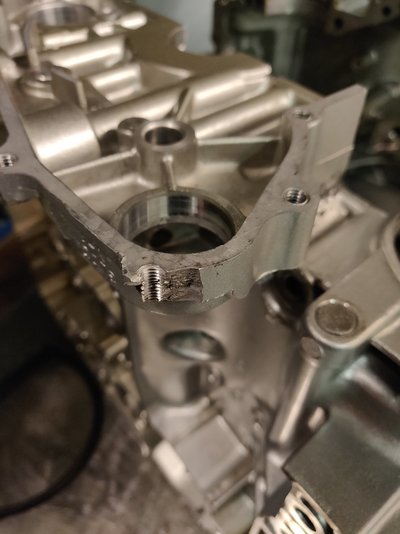

Build up with 4043 rods. Tig set to max 130 amp but using pedal....

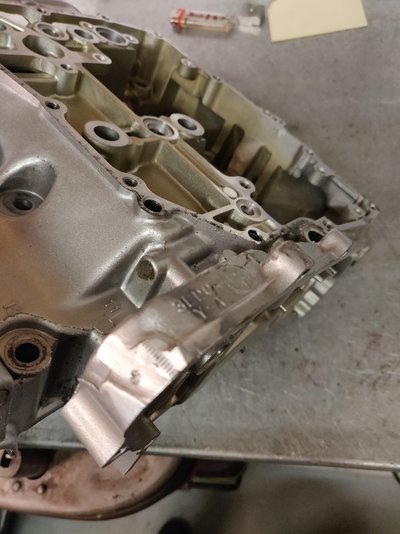

Filed into shape.....

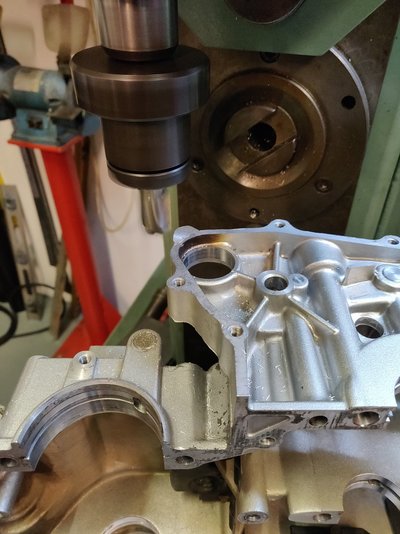

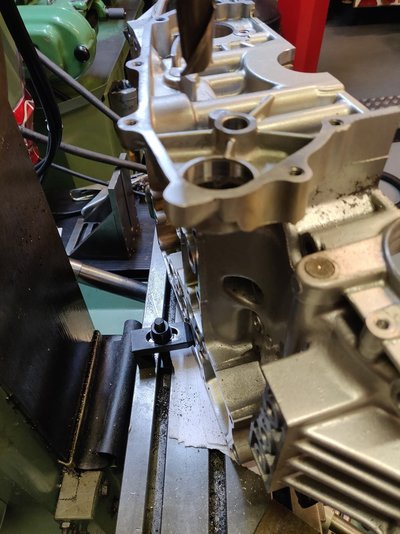

Just need to put in mill to skim the surface level and drill / tap an m6 hole.

Job for tomorrow now I think....

Yamaha TDM 850 broken starter motor mounting lug on crank case.

Here is the damage......

Cleaned up ready for Tig.....

Build up with 4043 rods. Tig set to max 130 amp but using pedal....

Filed into shape.....

Just need to put in mill to skim the surface level and drill / tap an m6 hole.

Job for tomorrow now I think....