I've taken on a little bit of work welding/repairing the front bodywork of a Mk1 Golf, for a friend. The rest of the car is remarkably rot-free, basically what seems to have happened is most of the usual rusty areas have been addressed before, including sill repairs, rear panel, underneath. But they obviously didn't look at the front, except a bodged repair which I've found, where they slapped a plate over a dodgy area, leaving it to rust underneath even worse!

Anyway, here's the (lots of) pics so far.

Car arrives:

Count the cars!

Front part of inner wing is cut off and previously spot-welded areas carefully ground off:

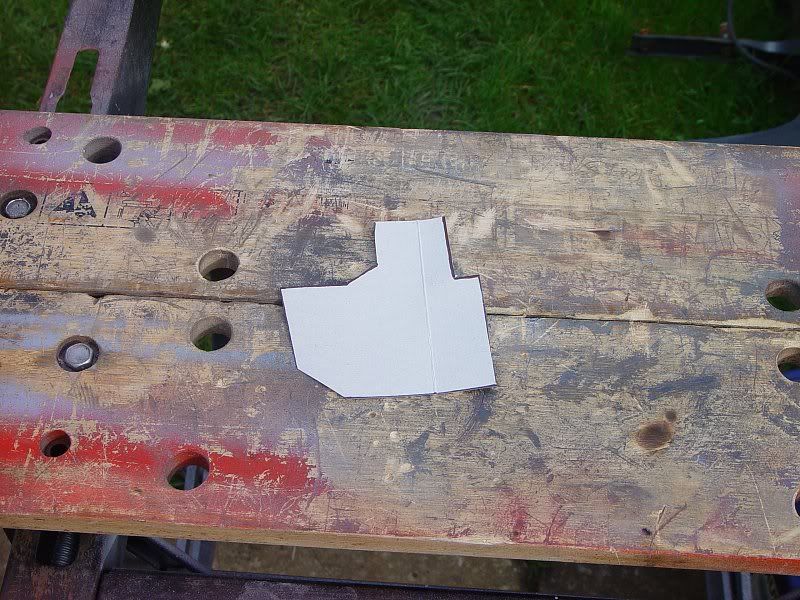

The front panel needs repairs to its flanges. Cut out rusty area:

Small repair piece:

Ready to weld:

Tacked in place:

Remaining welds done (butt welding):

Welds ground neat (yellow in appearance, due to reflection from other areas on car!):

Another area needing repair:

And another. Cardboard template for this more complicated shape:

Transfer to sheet metal:

Cleaned up:

Bent into shape:

Trial fitting:

After some adjustments, more/less ready to weld in:

And welded in place:

Then painted in primer for now:

So, now its ready for the large repair panel. 1st fitment:

Drilling, to allow plug welds to front panel and battery tray:

And front panel drilled for plug welds:

Trimmed accurately, ready to weld:

And its secured:

Next area. Yuk!:

After the sealant was removed (which needed high pressure degreaser and toothbrush assistance, it could be seen a repair panel had been crafted and slapped over rust:

Eventually, this was removed. Tricky access meant disconnecting suspension:

Previous welds now smoothed down and in primer:

Anyway, here's the (lots of) pics so far.

Car arrives:

Count the cars!

Front part of inner wing is cut off and previously spot-welded areas carefully ground off:

The front panel needs repairs to its flanges. Cut out rusty area:

Small repair piece:

Ready to weld:

Tacked in place:

Remaining welds done (butt welding):

Welds ground neat (yellow in appearance, due to reflection from other areas on car!):

Another area needing repair:

And another. Cardboard template for this more complicated shape:

Transfer to sheet metal:

Cleaned up:

Bent into shape:

Trial fitting:

After some adjustments, more/less ready to weld in:

And welded in place:

Then painted in primer for now:

So, now its ready for the large repair panel. 1st fitment:

Drilling, to allow plug welds to front panel and battery tray:

And front panel drilled for plug welds:

Trimmed accurately, ready to weld:

And its secured:

Next area. Yuk!:

After the sealant was removed (which needed high pressure degreaser and toothbrush assistance, it could be seen a repair panel had been crafted and slapped over rust:

Eventually, this was removed. Tricky access meant disconnecting suspension:

Previous welds now smoothed down and in primer:

this up in the next couple of months. keep the pics coming.

this up in the next couple of months. keep the pics coming.